Alphabetical Index

Chemical Composition of Steels

Keyword Search

Steel Names

Alloyed Steels

Carbon Steels

Cast Irons

Chromium Steels

Cold Work Tool Steels

Creep Resistant Steels

Hot Work Tool Steels

Molybdenum Steels

PM steels

Stainless Steels

Structural Steels

Tool Steels

Vanadium Steels

White Cast Irons

M2C Carbides

M3C Carbides

M7C3 Carbides

M23C6 Carbides

MC Carbides

Light Microscopy

EDS/WDS Microanalysis

Scanning Electron Microscopy

Transmission Electron Microscopy

X-Ray Diffraction

Help

Contact Us

Home

Carbides in NCWV/D3 steel

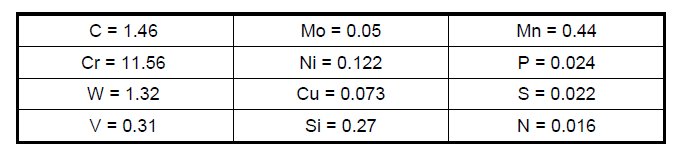

Table 1: Composition of material for the study, NCWV/D3 steel, in wt%

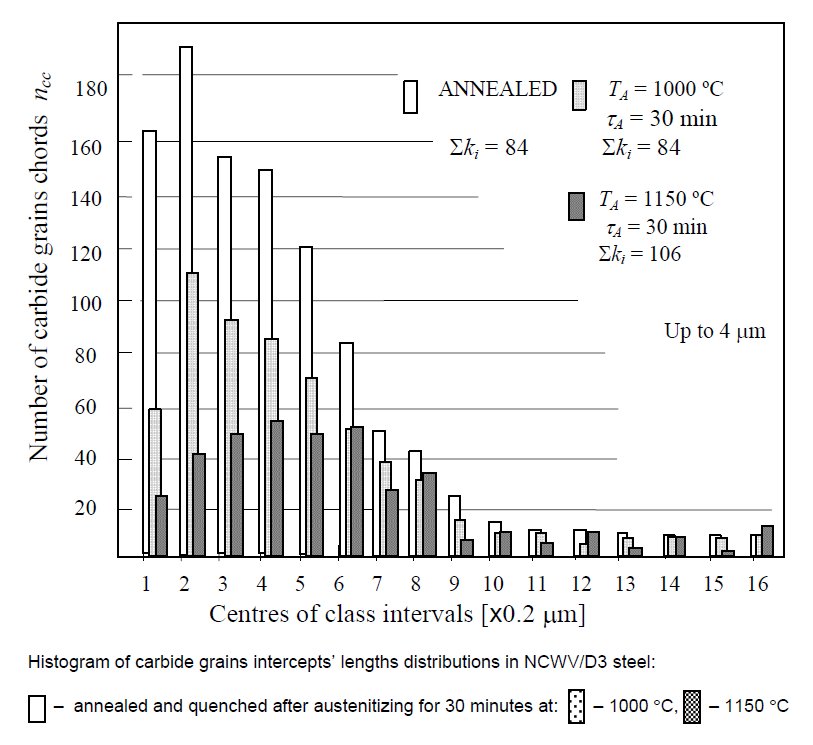

Figure 1: Histogram of carbide grains intercepts’ lengths distributions in NCWV/D3 steel.

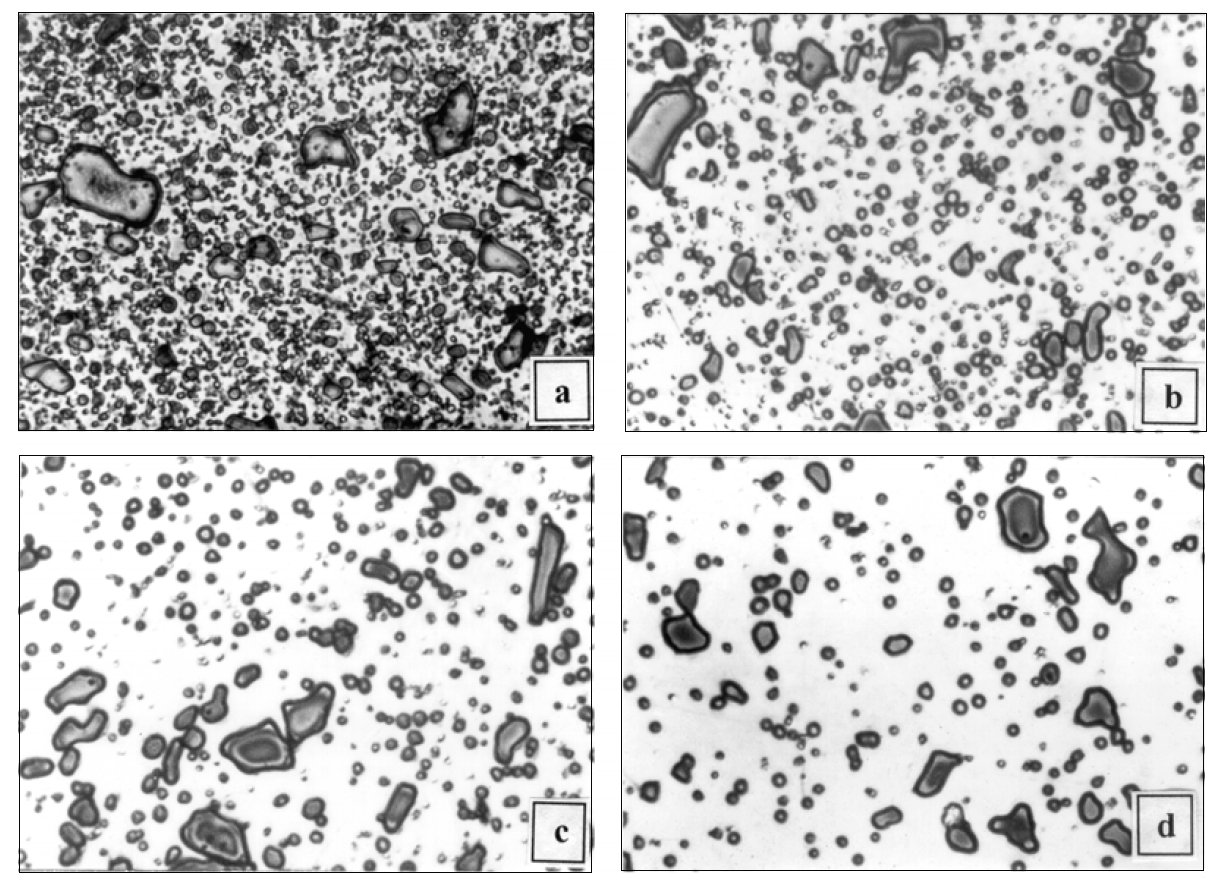

Figure 1: Picture of carbide grains in NCWV/D3 steel: (a) in the soft annealed state, (b,c,d) quenched after austenitizing for 30 minutes at: (b) 950 C, (c) 1050 C, and (d) 1150 C. Murakami’s reagent was used for etching. Magnification 1,000x.

Carbide name: Carbides

Record No.: 730

Carbide formula: No data

Carbide type: No data

Carbide composition in weight %: No data

Image type: LM

Steel name: NCWV/D3 steel

Mat.No. (Wr.Nr.) designation: 1.2080

DIN designation: X210Cr12

AISI/SAE/ASTM designation: AISI D3

Other designation: No data

Steel group: Cold work tool steels

Steel composition in weight %: See the table 1.

Heat treatment/condition: Heat treatment of samples of diamter = 12 mm, length = 60 mm, assigned for determination of carbides contents using method of electrolytic extraction at 900 to 1150 °C and austenitizing times of 10, 30, and 90 minutes, was performed in a furnace with protective environment/atmosphere of technically clean nitrogen. The accuracy of temperature control was ±2 °C. After the austenitizing the samples were quenched in a hardening oil. To avoid eventual decarbonated layer the samples surface was ground on centreless grinder to remover the layer of thickness at least 0.5 mm.

Note: The NCWV/D3 tool steel was the subject of the study. In the course of the investigation carried out it was found that during austenitizing of the steel the carbides contents decreased from 24.84 wt% in the annealed state down to 13.33 wt% after austenitizing at 1150 °C during 30 minutes. It was also stated that the carbides contents in the quenched steel after austenitizing in the temperature range from 900 to 1150 °C during 30 minutes may be determined from the equation. Dissolution of carbides during austenitizing brings about the increase of elements Cr, W, and V contents in austenite up to 7.27%, 1.06%, and 0.086%, respectively, after austenitizing at 1150 °C during 30 minutes. It was also noticed that there is a rectilinear correlation between the contents of dissolved carbides in austenite and the contents of Cr and W in matrix of the tool steel quenched after austenitizing in the temperature range from 900 to 1150 °C and constant time of 30 minutes.

The electrolytic extraction of carbides was carried out in a 5%-HCl acquaeous solution of specific gravity of 1.19 g/cm3, with the current density of 10 mA/cm2. The extraction time was 18 to 20 hours. The carbides extraction method in details has been presented in literature. Percentages of Cr, W, and V in matrix of the quenched steel samples were determined by performing chemical analysis of electrolytes obtained after the carbides extraction. The percentage of chromium was determined by a potentiometric method whereas of tungsten and vanadium by a colorimetric method.

According to the study results presented in for the experimented steel, and by Geller for the X12M steel of similar composition, apart from the chromium carbides of M7C3 type, the carbides of M23C6 type occur in very small amount which dissolve completely in austenite during austenitizing steel at 1050 °C during 30 minutes [8]. The occurrence of carbides of M23C6 in NCWV/D3 steel was also identified by Kaluza.

Big primary carbides of the investigated NCWV/D3 steel annealed and quenched after austenitizing in the temperature range from 900 to 1150 °C for 30 minutes usually possess irregular shape, whereas lesser secondary carbides possess spheroidal or close-to-spheroidal shape.

It results from histograms presented in Fig. 1 that in rods of diameter 13 mm of the investigated NCWV/D3 stee obtained by forging and then soft annealed the distribution of carbide grains intercepts’ lengths is close to logarithic-normal with carbides of 0.4-mm intercepts’ length being the most numerous fraction.

Qualitatively similar distributions were obtained in samples of the quenched steel after austenitizing at 1000 and 1150 °C, with decreasing number of carbides of the least dimensions, that is of intercepts’ lengths down to about 1 ěm, occurring.

In the quenched steel after austenitizing at 1000 °C during 30 minutes still the most numerous fraction are the carbides of intercepts’ lengths of 0.4 ěm whereas after austenitizing at 1150 °C the carbides fractions of intercepts of 0.6 to 1.2 ěm. Micrographs of carbides of the investigated NCWV/D3 steel annealed and quenched after austenitizing at 950, 1050, and 1150 °C respectively, for 30 minutes are presented in Fig. 2.

Links: No data

Reference: Not shown in this demo version.