Alphabetical Index

Chemical composition

Keyword Search

AFNOR Steels

AISI/SAE Steels

BS Steels

DIN Steels

EN Steels

JIS Steels

JUS Steels

GB Steels

GOST Steels

Mat.No (Wr.Nr.) Steels

Alloy Steels

Boron Steels

Carbon Steels

Case Hardening Steels

New Diagrams

Nitriding Steels

Spring Steels

Steel Companies

Structural Steels

Tool Steels

Help

Home

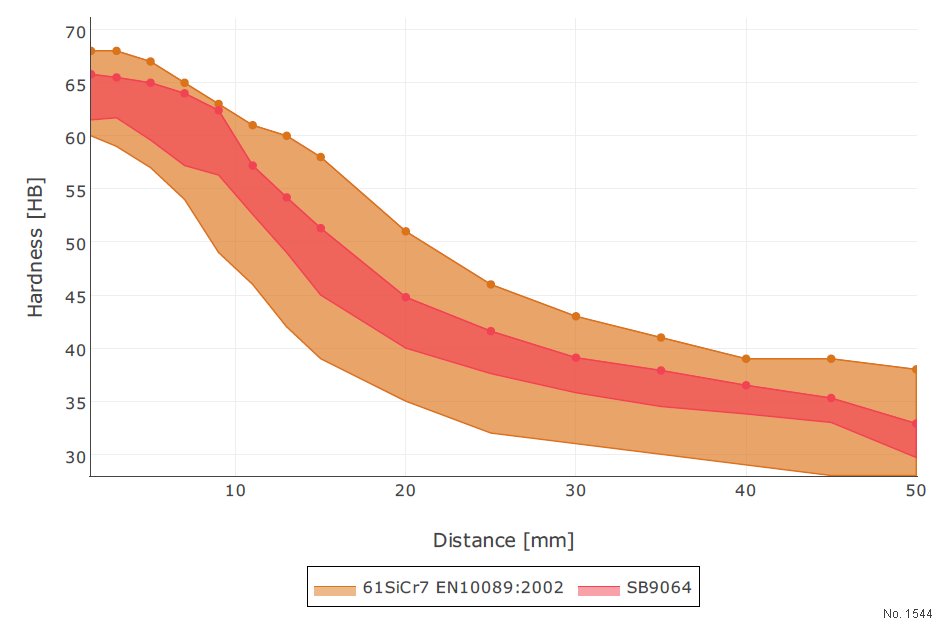

61SiCr7 Steel

Steel name: 61SiCr7

Diagram No.: 1544

DIN designation: 61SiCr7

Chemical composition in weight %: 0.59-0.64% C, 1.60-1.80% Si, 0.70-0.90% Mn, 0.035% P, 0.025% S, 0.20-0.40% Cr

Steel group: Spring steels

Applications: 61SiCr7 is a Silicon Manganese alloy steel mainly used for heavy duty springs, but also used for tooling where impact resistance is of importance. As-quenched hardness is expected to fall within a range of about 58 - 63 HRC. Hardenability is considered fairly high.

Comment: Ms=238 C, Ac1=772 C, Ac3=814 C.

Reference: Not shown in this demo version.

Heat Treatment

Hardening: 870oC/in oil

Tempering: Tempering at min. 150 C immediately after the temperature after hardening has reached 40 -50 C

Hardenability Diagram

Click the image to enlarge the diagram.

Disclaimer: The material data is a central depository of information based on global actual tests and calculated software data that is available to the public for a fee. The information and data presented herein are typical or average values and are not a guarantee of maximum or minimum values. Applications specifically suggested for material described herein are made solely for the purpose of illustration to enable the reader to make his own evaluation and are not intended as warranties, either express or implied, of fitness for these or other purposes. There is no representation that the recipient of this literature will receive updated editions as the become available.