Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Cr Layer - Dry Etching

Material Name: Cr

Recipe No.: 10298

Primary Chemical Element in Material: Layer

Sample Type: Layer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: The etching of thick Cr layers at a submicron scale has not been performed in detail so far,

partly due to the hardness of Cr, which makes the etching difficult. Furthermore, the following

deep oxide etching process necessitates a large Cr thickness (>= 150 nm), which leads to aspect

ratios of 0.5 for the 300 nm-large pores and 1 for the 150 nm-thick pore walls. Such aspect

ratios are very high for a metal layer. Taking into account the small resist thickness limited by

the e-beam lithography process, and the diversity of the resists used in this project, we had to

find an optimal procedure, allowing to etch small features in Cr with aspect ratios around 0.5

and a selectivity better than 1:3 to any kind of resist. Furthermore, the etching of small samples

requires the samples to be glued on a 4” substrate, e.g., a silicon dummy wafer. Since the glue

used possess a low thermal conduction, the process to be designed should also be temperature

independent.

Procedure (Condition): No data

Note: No data

Reference: Electron-Beam Lithography, Experimental Fabrication, pp. 69-89, Source not known.

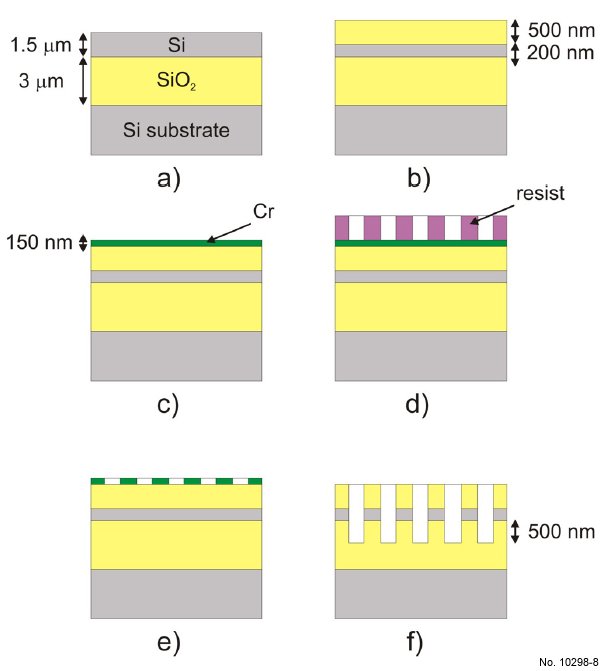

Figure 1: Full process designed to fabricate the IOSOI PPCs. a) Initial SOI wafer, b) formation of the

silicon core and the upper oxide cladding via thermal oxidation steps followed by wet etching in HF, c)

deposition of the Cr mask by sputtering, d) electron-beam lithography, e) patterning of the Cr mask and

f) patterning of the IOSOI structure.

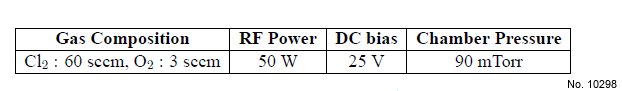

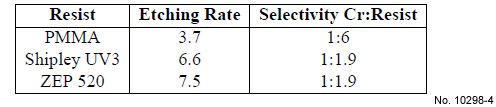

Table 1: Starting recipe used for the optimization of the Cr etching process.

Figure 2: Cross sectional SEM images of the sample after Cr etching with the recipe optimized for

larger feature sizes (given in table 1). The left picture was obtained by tilting the sample 15 deg. towards

the surface.

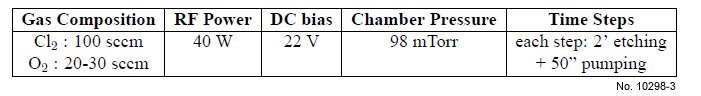

Table 2: Results of the Cr etching using the optimized recipe and the three types of resists.

Table 3: Optimized recipe used for the Cr etching process.

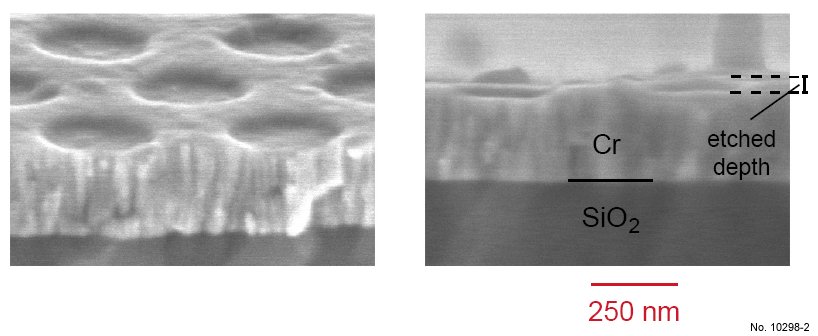

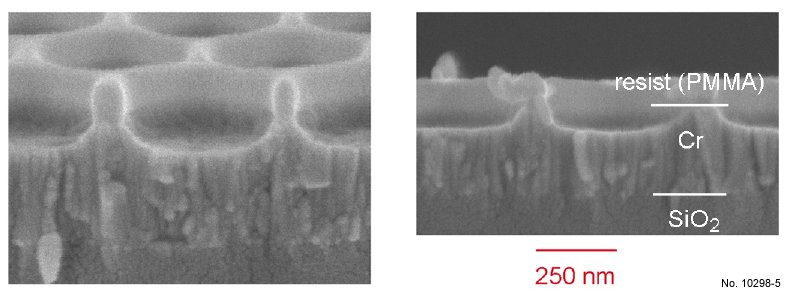

Figure 3: Cross sectional SEM images of the sample after Cr etching using the optimized recipe and

a 700 nm-thick PMMA mask. The total thickness of the Cr layer was 400 nm. The left picture was

obtained by tilting the sample 15. towards the surface.

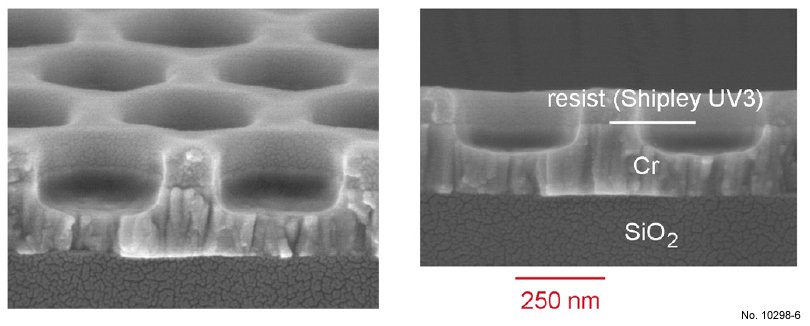

Figure 4: Cross sectional SEM images of the sample after Cr etching using the optimized recipe and

a 350 nm-thick Shipley UV3 mask. The total thickness of the Cr layer was 400 nm. The left picture was

obtained by tilting the sample 15. towards the surface.

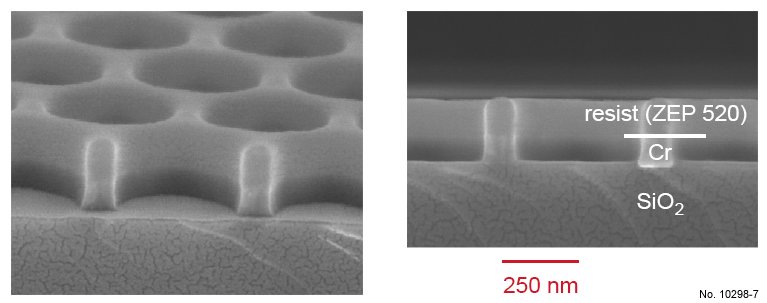

Figure 5: Cross sectional SEM images of the sample after Cr etching using the optimized recipe and

a 400 nm-thick ZEP 520 mask. The total thickness of the Cr layer was 140 nm. In this case, the resist

layer was thick enough to etch through the whole Cr layer. The left picture by obtained via tilting the

sample 15. towards the surface.