Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Diamond Thin Film - Laser Etching

Material Name: Diamond

Recipe No.: 10305

Primary Chemical Element in Material: C

Sample Type: Thin film

Uses: Etching

Etchant Name: None

Etching Method: Laser etching

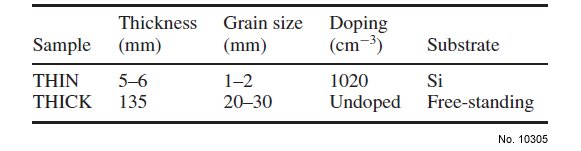

Etchant (Electrolyte) Composition: Two thicknesses of thin film diamond deposited by the

technique of microwave plasma enhanced chemical vapour

deposition (MWPECVD) have been employed in this

study. The properties of these two films designated THIN

and THICK are summarized in table 1. Both types of

films displayed a morphology consisting of randomly aligned

coalesced crystallites. Prior to laser processing and subsequent

characterization, the samples were subjected to a wet etching

treatment consisting of immersion in a saturated solution

of H2SO4:NH4(SO4) (30 min, 200 C) followed by a

H2O2:NH4OH solution (15 min, boiling); this has been shown

to remove surface graphitic layers. An excimer laser

(Lambda Physik LPX305i) operating at 193 nm (ArF) with

an average pulse duration of 20 ns was used throughout. The

output beam of the laser system, measuring 20 mm ~ 10 mm,

was directed onto a chrome-on-quartz mask; the mask pattern

was then directly projected via a 10:1 reduction lens system

(NA = 0.05) onto the sample placed on a microprocessor

controlled x-y-z stage. The system has been described in

more detail elsewhere. SEM images were recorded using

a Hitachi S800 instrument; film profiling was carried out

using a Tencor Instrument profilometer. Raman scattering

analysis was performed with a Renishaw System 2000 Raman

spectrometer (He.Ne (632.8 nm) laser excitation). AES was

carried out in an ultra-high vacuum (UHV) chamber with a

base pressure 5 x 10 exp(-10) Torr. A primary electron beam

energy of 3 kV was used throughout with a low beam current

(1 µA) to minimize electron induced damage within the

surface region; a Varian 981-2707 cylindrical mirror analyser

(CMA) and associated electronics was used to produce

differential Auger spectra. Electrical measurements were

made using a Hewlett Packard HP4140B semiconductor

parameter analyser.

Procedure (Condition): No data

Note: Excimer laser projection patterning with an ArF (193 nm) source has been

employed in the irradiation of thin diamond films. The effect of a number of

process parameters including laser fluence and processing ambient on the

quality of the etch product has been investigated; scanning electron

microscopy shows that good control of etch quality may be achieved with

excellent lateral reproduction of images down to 2 ìm. Raman scattering

and Auger electron spectroscopy of irradiated films have been correlated,

and modifications in the diamond surface have been quantified according to

processing parameters. Electrical tests on laser modified surfaces show that

the reactivities of metals have a major role in the performance of contact

metallizations on such a material. The viability of excimer laser etching of

diamond as a manufacturing technique is considered.

Reference: Simon S M Chan, et al., The effect of excimer laser etching on thin

film diamond, Semicond. Sci. Technol. 18 (2003) S47–S58.

Table 1: Details of diamond films used within this study. ‘Grain size’ is the average size of the grains on the top surface of the film as judged by scanning electron microscopy.