Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Si Wafer - Dry Etching

Material Name: Silicon

Recipe No.: 10308

Primary Chemical Element in Material: Si

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

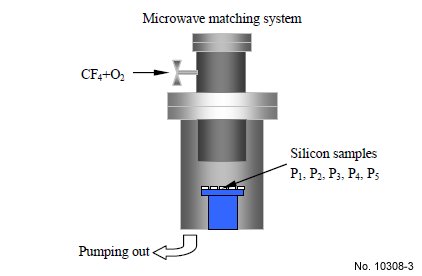

Etchant (Electrolyte) Composition: Figure 1 shows a schematic diagram of the experimental apparatus. A CF4 and O2 gas mixture was discharged within a

stainless steel chamber by applying a 2.45 GHz microwave to generate fluorine and oxygen atoms, which were

transported into a reaction chamber evacuated to less than 1 x 10 exp(-2) Torr. The samples were placed 140 mm away from the

discharge region. The samples were n-type, (111) single crystalline silicon. The maximum power of the igniting

microwave was 500 W. The pumping system was at the sidewall of the bottom of the process chamber and gases entered

the chamber from side above.

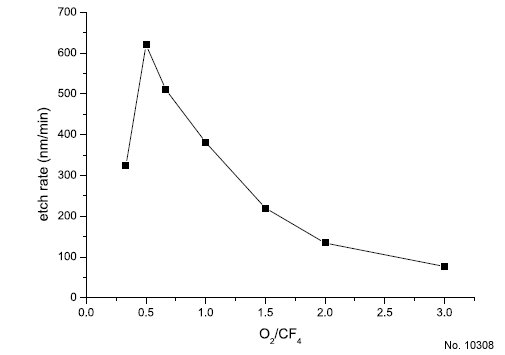

The etching rate of single crystalline Si as a function of the O2 to CF4 flow rate ratio under a constant pressure of 0.3 Torr.

The CF4 flow rate was fixed at 44 seem in this experiment. At small O2 concentrations with flow rate ratios less than 0.5,

the Si etching rate increased with increasing flow rate. This can be explained by the increase of the amount of fluorine

atoms by adding O2 to CF4 owing to the oxidation of CF, in the discharge and transportation regions. On the other hand,

the Si etching rate decreased with increasing O2 flow rate when the flow rate ratio exceeded 0.5. The reason for this

behavior was considered to be due to the adsorbed oxygen molecules or oxidized layer formed on the surface, which

prevented fluorine atoms from reacting with Si.

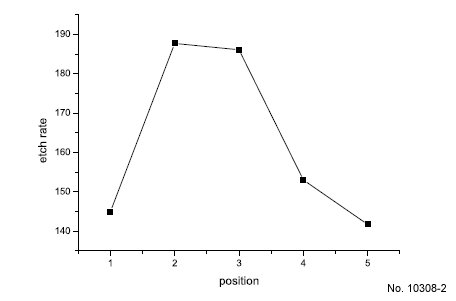

The etch rate along the diameter of the holder with same other conditions varied, and the different position on the holder

is shown in Fig. 1. If mass flow rate of CF4 was fixed at 44 sccm, the chamber pressure was set at 0.3 torr, and the

sample holder was at room temperature, the distribution of the etch rate is shown in Fig. 4.

Procedure (Condition): No data

Note: Silicon is one of the most common materials used in optical micro-electro-mechanical systems (MEMS). For the

optical applications the surface quality plays a vital role in the performance of elements, so the control of surface

morphology, such as surface smoothing, is very important to produce optical MEMS elements with high reliability and

high quality. The most commonly used etching methods such as reactive ion etching (RIE) always left damage layer on

the etched surface leaving the surface with high roughness. In this paper 2.54 GHz micro wave excited plasma was used

to treat the silicon surface, and the different etching conditions of CF4 and O2 mixture were investigated. The surface

quality after this down-stream plasma treatment was studied by atomic force microscopy (AFM) measurement.

Reference: Hui Ju, Wenkui Wang, The surface treatment of silicon wafer by microwave down-stream

plasma etching, Proceedings Volume 6831, Nanophotonics, Nanostructure, and Nanometrology II; 683114 (2008) https://doi.org/10.1117/12.755881.

Figure 1: The down-stream plasma etching system.

Figure 3: The relation between etch rate and flow rate ratio of O2 and CF4.

Figure 4: The etch rate distribution along the diameter direction of the holder.