Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

ZrO2 Thin Film - Dry Etching

Material Name: ZrO2

Recipe No.: 10310

Primary Chemical Element in Material: Zr

Sample Type: Thin film

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

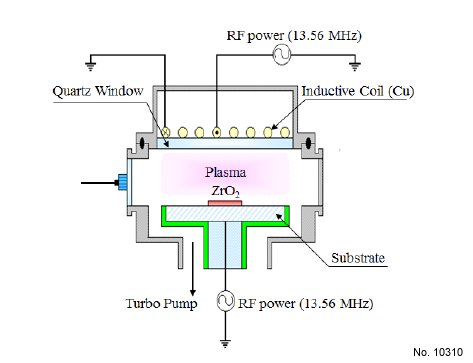

Etchant (Electrolyte) Composition: The ZrO2 thin films used in this work were deposited by

atomic layer chemical vapor deposition. The total thicknesses of

the ZrO2 thin films were about 100 nm. The dry etching process

was performed in an ICP system, as shown schematically in Fig.

1. This consisted of a cylindrical chamber with a diameter of 26

cm. The top copper coil was operated with 13.56 MHz RF power,

and was located on the chamber lid, to generate high-density

plasma. The bottom electrode was connected to another 13.56

MHz asymmetric RF generator, to control the DC-bias voltage.

The distance between a quartz window and the substrate electrode

was 9 cm. The chamber was evacuated to 10 exp(-6) Torr using a

mechanical pump (2M80, BOC Edwards) and a turbo molecular

pump. The ZrO2 thin films were etched with CF4/Ar gas mixing.

The gas mixing ratio and process pressure were varied, to find the characteristics of etching. For these experiments, RF power,

DC-bias voltage, process pressure and substrate temperature

were 600 W, - 250 V, 15 mTorr and 45C, respectively. In addition,

plasma etching of ZrO2 thin films was investigated by including

the RF power, DC-bias voltage, and process pressure of 500 W ~

650 W, - 150 V ~ - 300 V, and 9 ~ 20 mTorr in the CF4/Ar gas mixing

ratio. The etch rates were measured using a depth profiler KLA

Tencor, alpha-step 500; Sanjoe, Ca, USA). The chemical reactions on

the surfaces of the etched ZrO2 thin films were evaluated using

X - ray Photoelectron Spectroscopy (XPS, Thermo VG, SIGMA

PROBE; East Grinstead, West Sussex, England). The source type

for the XPS analysis was Al K alpha with a spot size of 400 µm. The energy step size was 0.1 eV.

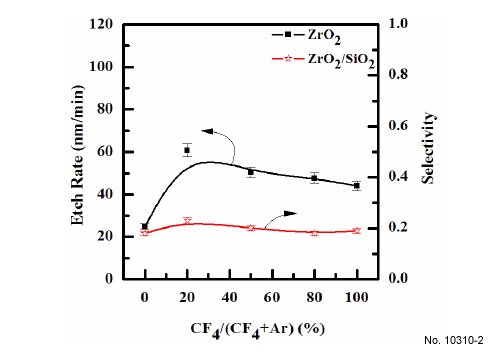

For the characterization of ZrO2 thin film in an ICP etching

system, the plasma etching of ZrO2 thin film and selectivity of

ZrO2 to SiO2 were systematically investigated as various etch

chemistries. Figure 2 shows the etch rate of ZrO2 thin film and

selectivity of ZrO2 to SiO2 as a function of reactive species concentration,

when the total flow rate was maintained at 20 sccm.

Other process conditions, such as RF power, DC-bias voltage,

process pressure, and substrate temperature, were maintained at

600 W, - 250 V, 15 mTorr, and 45C, respectively. Comparisons of

etch rates of the ZrO2 thin film in Ar- (25 nm/min) and CF4- (44.03 nm/min) based plasmas showed that the chemical etching was

more effective than physical sputtering [10]. The etch rate of

ZrO2 thin film increased, while the selectivity of ZrO2 to SiO2 also

increased. The maximum etch rate of ZrO2 was 60.8 nm/min at a

20% of CF4/(CF4+Ar) gas mixing ratio. It is well known that fluorine

components of ZrO2 thin film form high-volatile by-product,

such as ZrF4 (melting point: 450C). The evident enhancement

of the ZrO2 thin film etch rate in the pure CF4 plasmas allows

one to assume that the chemical etch pathway provided by the

F atom is the dominant mechanism for the given set of input

process parameters. In the case of the chemical etching of

the ZrO2 thin films, we expect the contribution of this pathway

to be much lower, compared with the ion assisted chemical reaction.

The reason for this is that for ion energies of about 300 - 500

eV, typical sputtering yields for metal oxides do not exceed 0.5 -

1 atom/ion. In CF4-based plasma, addition of the CF4 up to 20%

increased the etch rate through the action of two mechanisms: 1)

the accelerated chemical reaction by the ion-stimulated desorption

of the reaction products, and 2) increase of the contribution

of the chemical etching. Nevertheless, when the CF4 content exceeds

20%, the etch rate begins to fall, due to the gdisappearanceh

of the chemical etching.

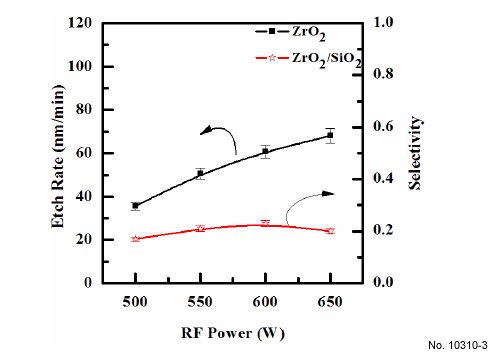

Figure 3 shows the etch rate of ZrO2 thin film as a function of

RF power. Other process conditions, specifically CF4/Ar(20:80%)

plasma, DC-bias voltage, and process pressure, were also maintained

at - 250 V, and 15 mTorr. As RF power increases, the ZrO2

thin film also increases, starting from 35.7 nm/min at 500 W, and

then reaches a maximum of 68.08 nm/min at 650 W. It can be

seen that an increase in RF power causes a monotonic increase

in both dissociation and ionization rates, and thus, in the densities

and fluxes of F atoms and positive ions. In our case,

such layer can result from the deposition of solid F that is then

bonded with surface oxygen to form Zr-F, as well as from F radicals

incorporated in the polymer-like structure.

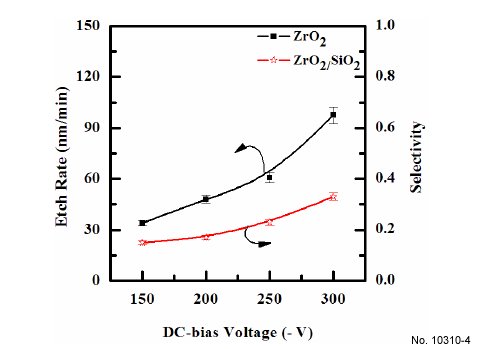

The etch rates of ZrO2 thin film are shown in Fig. 4 as functions

of the DC-bias voltage. Other process conditions, namely

CF4/Ar(20:80%) plasma, RF power and process pressure, were

also maintained, at 600 W, and 15 mTorr. As the DC-bias voltage

increases from - 150 to - 300 V, the etch rate of ZrO2 thin film

increases from 33.98 to 97.5 nm/min. The selectivity of ZrO2 to

SiO2 was slightly increased. An increase in etch rate can be related

to the increase of mean ion energy, resulting in increasing

sputtering yields for the ZrO2 thin film, and reaction products.

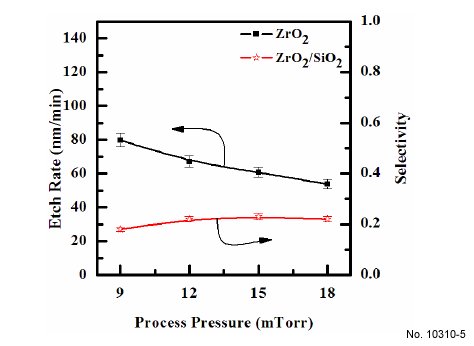

The effect of process pressure on etch rate is shown in Fig. 5. As process pressures increased from 9 to 20 mTorr, the etch

rates of ZrO2 decreased from 79.98 to 53.8 nm/min. However,

we obtain a similar non-monotonic behavior, as was mentioned

for the effect of the gas mixing ratio. In our opinion, the

effect of gas pressure can be explained as follows: an increase in

gas pressure at fixed CF4/Ar mixing ratio leads to an increase in

both density and flux of fluorine atoms on the etched surface,

but causes a decrease in ion flux and mean ion energy. As

a result, with increasing gas pressure, there is a tendency for

the chemical etch pathway to accelerate, but a worse condition

obtains for the ion stimulated desorption of reactive products,

probably resulting in a decreasing fraction of acceptable free

surface for chemical reaction [17]. Similar to the effect of the

gas mixing ratio discussed above, these two factors working in

opposite directions produce a non-monotonic behavior of the

etch rate.

Procedure (Condition): No data

Note: In this study, we carried out an investigation of the etching characteristics (etch rate, and selectivity to SiO2) of ZrO2

thin films in a CF4/Ar inductively coupled plasma (ICP) system. The maximum etch rate of 60.8 nm/min for ZrO2

thin films was obtained at a 20 % CF4/(CF4+Ar) gas mixing ratio. At the same time, the etch rate was measured as a

function of the etching parameter, namely ICP chamber pressure. X-ray photoelectron spectroscopy (XPS) analysis

showed efficient destruction of the oxide bonds by the ion bombardment, as well as an accumulation of low volatile

reaction products on the etched surface. Based on these data, the ion-assisted chemical reaction was proposed as

the main etch characteristics for the CF4-containing plasmas.

Reference: Han-Soo Kim, Jong-Chang Woo, Young-Hee Joo, and Chang-Il Kim, The Use of Inductively Coupled CF4/Ar Plasma to

Improve the Etch Rate of ZrO2 Thin Films, TRANSACTIONS ON ELECTRICAL AND ELECTRONIC MATERIALS, Vol. 14, No. 1, pp. 12-15, February 25, 2013.

Figure 1: Schematic diagram of the inductively coupled plasma system

for ZrO2 thin film etching.

Figure 2: Etch rates of ZrO2 thin films as a function of the CF4/Ar gas

mixing ratio. The RF power was maintained at 600 W, the DC-bias

voltage was - 250 V, the process pressure was 15 mTorr, and the substrate

temperature was 45C.

Figure 3: Etch rates of ZrO2 thin films as a function of the RF power. The

gas mixing was maintained at CF4/Ar(20:80%) plasma, the DC-bias

voltage was maintained at - 250 V, the process pressure was 15 mTorr,

and the substrate temperature was 45C.

Figure 4: Etch rates of ZrO2 thin films as a function of the DC-bias voltage.

The gas mixing was maintained at CF4/Ar(20:80%) plasma, the

RF power was maintained at 600 W, the process pressure was 15

mTorr, and the substrate temperature was 45C.

Figure 5: Etch rates of ZrO2 thin films as a function of the process pressure.

The gas mixing was maintained at CF4/Ar(20:80%) plasma, the

RF power was maintained at 600 W, the DC-bias voltage was - 250 V,

and the substrate temperature was 45C.