Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Si Wafer - Wet Etching

Material Name: Si

Recipe No.: 10312

Primary Chemical Element in Material: Si

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Wet etching

Etchant (Electrolyte) Composition: The technique involves minimal equipment, most of

which is readily available. The only specialized equipment is

a photoresist spinner, a contact mask, and a thermal oxidation

furnace. Other equipment includes ovens for soft and

hard baking of photoresist, an alignment fixture for holding

the mask in contact with the wafer, a temperaturecontrollable,

heater-jacketed Pyrex bath with a water-cooled

lid, magnetic stir bars, a hot plate/stirrer, and various Pyrex

and Teflon beakers capable of holding the wafers. The materials

required include (110) lightly doped silicon wafers

rhp >=0.1 Ogm x cm, photoresist, photoresist developer, hydrofluoric

acid (HF 50% in H2O), ammonium fluoride (NH4F 40% in H2O), concentrated sulfuric acid (H2SO4), 30% hydrogen

peroxide solution (H2O2 that is not stabilized is preferred,

stabilized H2O2 contains tin), potassium hydroxide (45%

KOH by weight in H2O), and isopropyl alcohol.

When reading this procedure, there are a few items to

keep in mind. First, any mention of water for mixing solutions

or rinsing means deionized H2O. For mixture recipes,

the proportions are volumetric, unless otherwise stated. Finally,

after each step involving an aqueous mixture, the wafers

should be rinsed in deionized H2O for 5 min then blown

dry with a moisture-free and oil-vapor-free gas.

A photomask of the desired pattern is needed for pattern

development on the masking layer. The one used here is

designed for trench production, and consists of 1.041 cm by

0.512 cm die patterned in chromium. Each die consists of 74

sets of five trenches, with 5, 10, 15, 20, and 30 mm widths.

They are separated by 10 mm lines that are the silicon walls

after processing. The trenches and walls are aligned with the

0.512 cm direction. Eight test patterns are dropped in around

the periphery and in the center of the wafer for quantification

of the etch process ~see Fig. 1!. Dimension tolerance, photoresist

exposure, wafer orientation marks, and 66 sets of

trenches make up the features of the diagnostics die.

The first step is to create the masking material on the

cleaned silicon wafers. A thermally grown oxide or nitride is

required. The layer needs to be thick enough to last until the

end of the second KOH etching step. A 7600 Å wet silicon

oxide layer is grown at ~1000 °C on 3-in. (7.5 cm)-diam

boron-doped (110) Si wafers. To estimate the thickness of the

masking layer required, the observed oxide etch rate in the

KOH baths is abut 10 Å/min. Including all process steps, a

1000 Å would have been sufficient in this example. The

silicon:silicon dioxide etch selectivity for the entire process

is about 3000:1.

Once the masking layer is grown, it needs to be patterned.

Shipley 1813 photoresist is applied to the wafer, then it is

spun at 3500 rpm for 30 s. The wafer is then softbaked at

95 °C for 30 min. After the photoresist is softbaked, the wafer

is mounted in the mask alignment fixture. The fixture

consists of two aluminum frames that can be tightly clamped

together. On one-half of the fixture there is an opening so

that the photomask is fixed in it with epoxy mounting seals.

The tolerances between the alignment pins and fixture holes

should be as small as possible to minimize slippage. The

wafer should be oriented such that a 35.3° counterclockwise

angle between the wafer flat and the desired patterned mask

lines is formed. This is a critical step, since the degree of

misalignment determines the amount of anisotropy achieved,

and the microscopic roughness of the sidewalls. A tolerance

of 62° is found to be adequate for the process, though alignment

within 61° is routinely achievable. When the fixture is

clamped together, the photoresist should be in contact with

the photomask everywhere on the wafer. Any gaps will lead

to poor image registration. The wafer is then exposed to the

ultraviolet (UV) light source. Exposure time will have to be

determined for each process, but the exposure used in this

case is 26 s for a Model 23 Optical Associates light source in

a Model 750 Optical associates mask aligner. It is important

to make sure the wafer is at a constant distance from the light

source to minimize exposure variation.

Photoresist developing is done in a 5:1 H2O: Shipley 351 Microposit developer for 45 s. (The developer is a NaOH,

surfactant, H2O mixture.) It is hardbaked at 140 °C for 30

min. After this coating, a backside coating of photoresist is

applied with another hardbake. The backside coating is used

to preserve the back side oxide. The wafer is then placed in

a buffered oxide etch (BOE) for 10–11 min, or until the

wafer becomes hydrophobic, to etch through the oxide masking

layer. A HF:NH4F 1:11 solution is used to inhibit swelling

and liftoff of the photoresist. The photoresist is then

stripped in a Piranha etch of concentrated H2SO4:30% H2O2

at 6:1, heated to 120 °C. (Depending on the hydrogen peroxide

temperature and age, it may not be necessary to apply an

external heat source.) It is recommended that the hydrogen

peroxide be refrigerated when not in use to prolong its lifetime.

The solution will turn yellowish once the wafer is

added to the solution, but will become clear once the photoresist

is fully removed. A thin oxide layer will form on the

silicon during the photoresist strip, so it is necessary to place

the wafer in the BOE for 30 s to remove the layer.

The next two steps are the most critical of the fabrication

process: the two KOH etches. The temperature tolerances are

very tight, because the etch rate can vary by more than 5000

Å/min within a 10 °C range. Therefore it is recommended

that a 61 °C tolerance be maintained. The first etch is 45%

KOH by weight in H2O heated to 80 °C. The solution is

placed in a heat jacketed Pyrex bath with stirring capabilities.

The bath needs to be covered to minimize fluid evaporation.

A water-cooled lid is recommended for fluid retention.

Stirring of the solution needs to be active enough to keep the

solution thoroughly mixed to minimize thermal and concentration

gradients ~120–150 rpm!. Place the wafers in the bath

only after it has reached its proper temperature. The etch rate

is about 3 mm/min with a typical anisotropy of 150:1. After

the etch the trench sidewalls have been formed. The sidewalls

are perpendicular to the face of the wafer after this

etch, but between the bases and the sidewalls are slanted

faces that are parallel to the (311) plane and protrude about

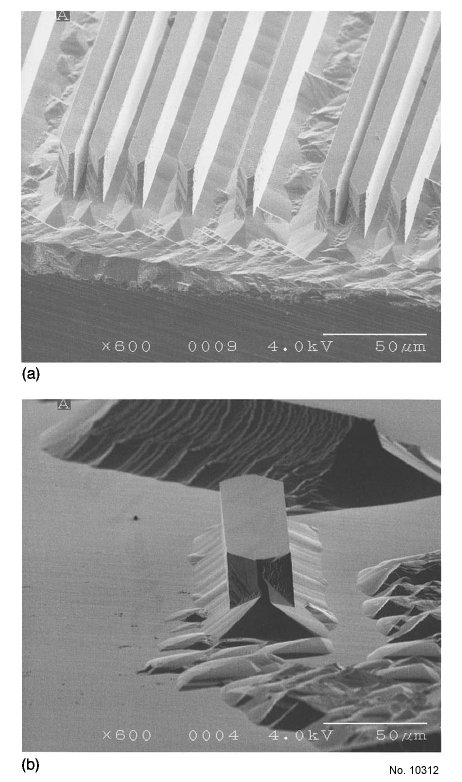

20 mm from the sidewall (see Figs. 1(a) and 1(b)).

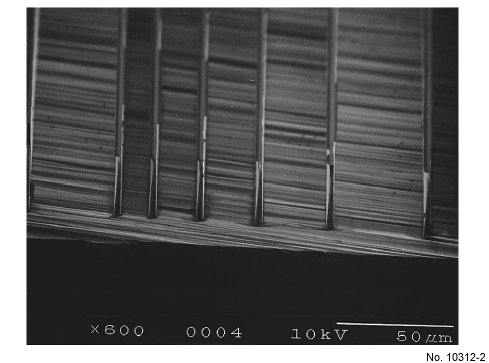

The second etching step uses a 25% by weight KOH in

H2O. The purpose of this etch is to remove the slanted faces

at the bottom of the trench. Once the KOH solution is in the

bath, a 5 cm layer of isopropyl alcohol is added to it. The

alcohol forms an immiscible layer on top of the KOH solution.

The alcohol can be mixed into the KOH by stirring at

about 120–150 rpm. The alcohol boils at 84 °C, so it is critical

that the bath always be kept below this temperature,

though the operating temperature of this bath is 8061 °C.

The bath needs to be stirred such that the alcohol layer is

mixed with the H2O. Wafers need to be spaced such that they

receive adequate circulation of the solution. The etch rate is

2500 Å/min, but the anisotropy is only 6:1 (see Fig. 2). This

etch attacks the slanted faces very effectively, and completely

removes them within 5–10 min. Longer etching risks

overetching in the lateral direction.

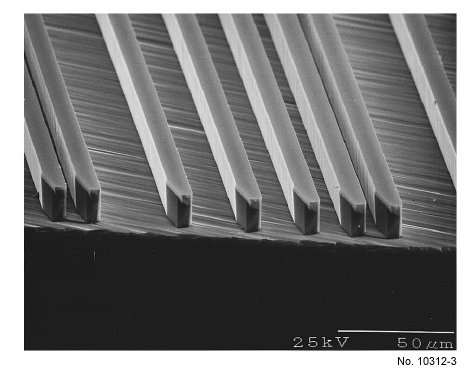

The last step is to remove the remaining masking oxide.

Typically 10–15 min in the BOE solution will suffice. The

wafer is rinsed for 5 min in H2O and then blown dry. After

this step the process is complete (see Fig. 3).

Figure 1 shows the effects of the 80 °C KOH, H2O etch

on (110) Si with the (111) aligned masking layer. The trench

walls are perpendicular to the (110) plane, and the etch rate

is about 2.5 µm/min. For the sample shown in Fig. 1(a), the

anisotropy is about 150:1, however, the trenches have slanted

bases. Other samples show trenches as deep as 40 µm, with

widths of 5 µm. Examining Fig. 1(b), in which there is more

than 100 µm between the walls, it can be seen that the slanting

face does not intersect the (110) plane. By measuring the

angles between the (111) and (110) planes with the slanting

plane, it is seen that the slant is about 32° from the (110), and

about 58° from the (111) face. This coincides with the (31T1)

plane intersecting the (111), and (1T0) planes. These slanting

layers are also seen for closely spaced grooves etched into

(110) silicon by Bean and Kendall. Also, the ends of the

trenches have been etched into other planes. The plane of the

ends of the trenches is (112).

Figure 2 shows the effect of the KOH/H2O/isopropyl alcohol

etch on another wafer. The sidewall etching is much

more pronounced, and the anisotropy is about 6:1 with an

etch rate of about 2500 Å/min. However, the most important

feature to note is the absence of the slanted plane. It is not

possible to see the slanted plane under any magnification.

The etch rate of this process is similar to that measured by

Price under similar conditions.

By combining the two etches, it is possible to get the best

features of both etches. The KOH/H2O etch is applied to

create the trench, with KOH/H2O isopropyl alcohol to remove

the slanted plane at the bottom. The result of the twostep

etch is shown in Fig. 3. The overall process anisotropy

is about 50:1 for the silicon. Of course this will vary to some

degree depending on the relative etching times of the two

solutions. One problem encountered during etching is that

the 5 µm trenches experienced a slightly lower etching rate

of about 3%. This is probably caused by poor fluid transport

within the trench. It should be noted, however, that poor

stirring during the second etch will destroy the patterned

features. Therefore, spacing of the wafers in the bath and the

degree of mixing must be carefully adjusted and maintained.

Procedure (Condition): No data

Note: A simple technique for creating trench structures in silicon using readily available wafer processing

techniques is discussed. By using orientation dependent etching of ~110! Si, it is possible to create

trenches in silicon with vertical sidewalls. The etching anisotropy of certain solutions used with this

technique is greater than 600:1 [110]:[111] etching, making it possible to fabricate virtually any

value of aspect ratio trench. For this technique, which makes use of two etchants, an anisotropy

of 50:1 is demonstrated. The equipment, materials, and processing steps required are

outlined.

Reference: Jeremy A. Theil, Deep trench fabrication by Si (110) orientation dependent etching, J. Vac. Sci. Technol. B 13(5), Sep/Oct 1995, pp. 2145-2147.

Figure 1: (a) Scanning electron microscopy secondary electron image of

etched trenches using 80° 45% KOH in H2O for 5 min. (b) Scanning electron

microscopy secondary electron image of etched mesas using 80° 45%

KOH in H2O for 5 min.

Figure 2: Scanning electron microscopy secondary electron image of etched

trenches using 80° 25% KOH in H2O and isopropyl alcohol for 120 min.

Figure 3: Scanning electron microscopy secondary electron image of etched

trenches using a combination of the two etchants, each for 5 min.