Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Nano-Fabrication of 30 nm Size MTJ - Silicon - Dry Etching

Material Name: Silicon

Recipe No.: 10313

Primary Chemical Element in Material: Si

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: See the data file.

Procedure (Condition): No data

Note: No data

Reference: Bernardo Josť Calmeiro Pires, Sub-100 nm Spintronic devices on large area wafers, MSc Thesis, Technico Lisboa, 2016, pp. 6, 10.

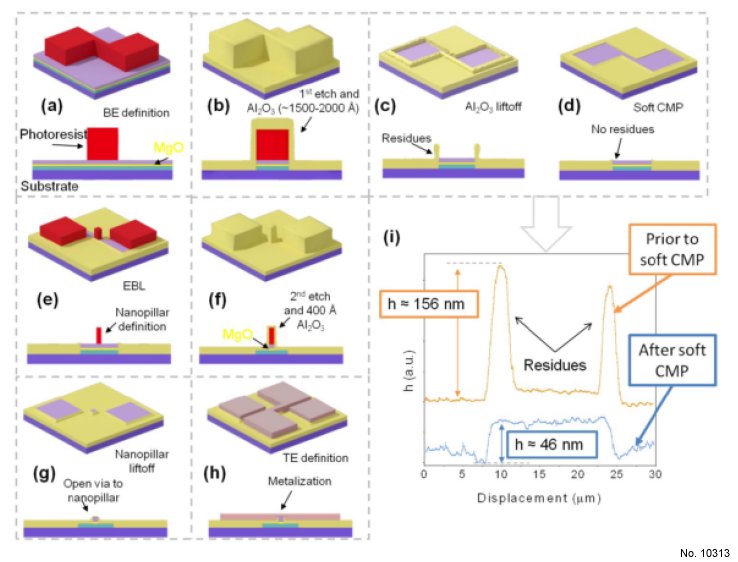

Figure 1: Layout of the nano-fabrication process. (a) BE definition by using optical lithography. (b) Stack full

etch and passivation with a thick Al2O3 layer. (c) Oxide lift-off leaving residues. (d) Removal of oxide residues

using a soft CMP step. (e) Nano-pillar definition and pads protection using EBL. (f) Second etch in two steps and

passivation with a thin Al2O3 layer. (g) Opening of the via to the nano-pillar by oxide lift-off. (h) TE definition by

optical lithography and metallization. (i) Profilometer scans of BE following the thick oxide lift-off (c) and after being

submitted to a soft CMP step (d) to remove lift-off residues.

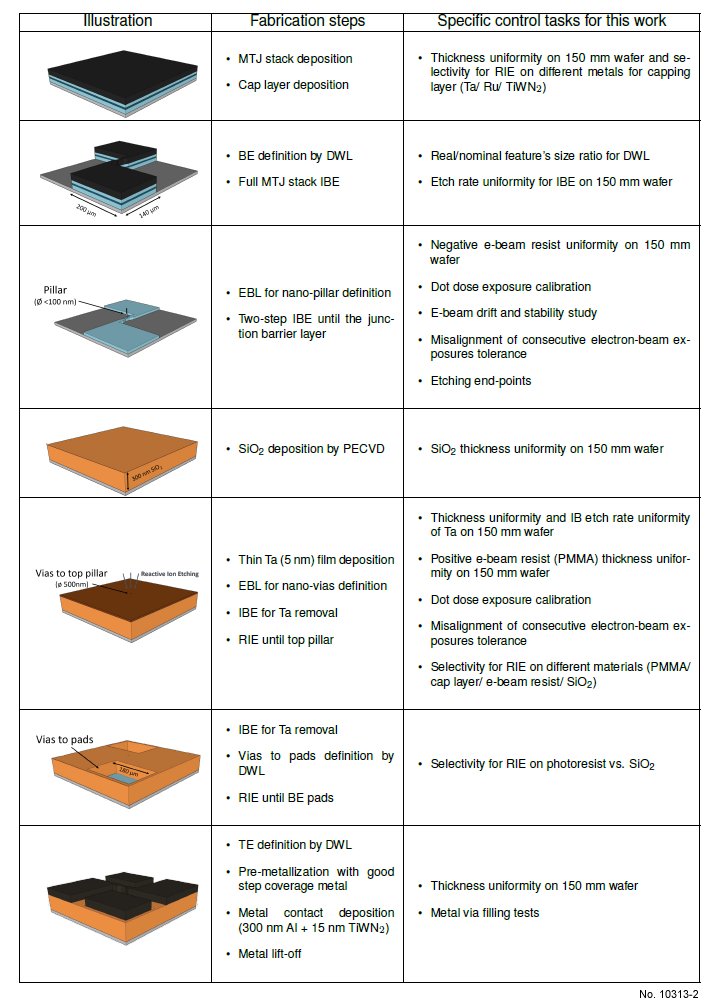

Figure 2: Nano-fabrication of 30 nm size MTJ in 150 mm wafer using RIE approach to open via to pillar.