Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

TiN Metal Hardmask - Wet Etching

Material Name: TiN

Recipe No.: 10317

Primary Chemical Element in Material: Ti

Sample Type: Layer

Uses: Etching

Etchant Name: None

Etching Method: Wet etching

Etchant (Electrolyte) Composition: Residue removal experiments were conducted in beakers at

45ºC for 2 minutes. The residue removal efficiency was

evaluated from SEM results (Hitachi S-5500) in the areas of

etched sidewalls, via bottoms and on the tops of the wafer.

The Cu etch rate experiments were conducted at 30 °C and

40 ºC and Cu experiments were at 30 ºC, 40 ºC and 55 ºC; each

experiment was 10 minutes in duration. TiN etch rate

experiments were conducted at 30 °C for 10 minutes, 40 ºC for

7 minutes and 55 ºC for 5 minutes. The etch rates were

calculated as the difference in thickness, before and after,

divided by the chemical treatment time. The TiN, Co and Cu

thicknesses were measured using a Four Point Probe Meter

333A. The TEOS, low-k and SiON etch rate experiments were

conducted at 30 °C, 46 ºC and 55 ºC for 10 minutes each. The

TEOS thickness was measured with KLA-Tenor SM300. Lowk

and SiON material thicknesses were measured with Auto SE

Spectroscopic Ellipsometer by HORIBA JOBIN YVON.

The hydrogen peroxide used for HCX-T002C formulation

was semiconductor grade PURANAL (Aldrich 40267), and

semiconductor grade hydrogen peroxide by VWR (JT2190-3)

was used for the HCX35 series formulation study.

The test for Cu oxidation barrier functionality was

conducted by first removing CuOx from Cu blank wafer pieces

with an in-house procedure. Then the Cu wafer pieces were

treated with the experimental product under study: HCXT002C

at 50 ºC, HCX35 at 55 ºC or HCX35-1 at 55 ºC, each

for 2 minutes followed by a 5 minute deionized water (DIW)

rinse and dry. Another Cu blank wafer piece with CuOx

removed was used as a control, with the only treatment being a

5 min DIW rinse and dry. SEM was used to examine the CuOx

growth on all three Cu blank wafer pieces.

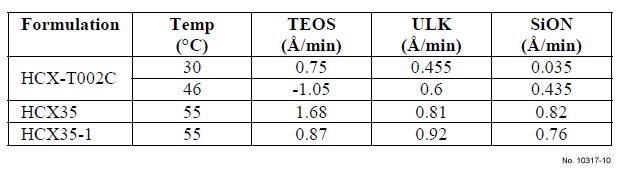

Fig. 1 shows that the TiN etch rate is increased with

increasing H2O2 concentration at 30 ºC and pH 9.2. In the

absence of hydrogen peroxide the TiN etch rate is zero. H2O2

is used to oxidize TiN to permit removal of TiN. The low Cu

etch rate (<2 Å/min) shown in Fig. 1 is due to the presence of

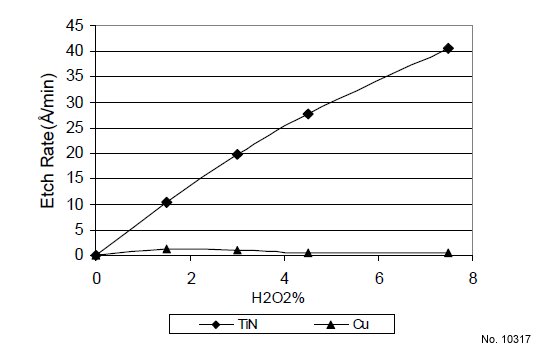

the Cu corrosion inhibitor which prevents Cu from being oxidized and subsequently removed during the process. Fig. 2

shows that the TiN etch rate is increased with “compound A”

concentration at 45 ºC. In the absence of “compound A”, the

TiN etch rate is about 62 Å/min. With 1.5% “compound A” in

the formulation the TiN etch rate is nearly doubled. To further

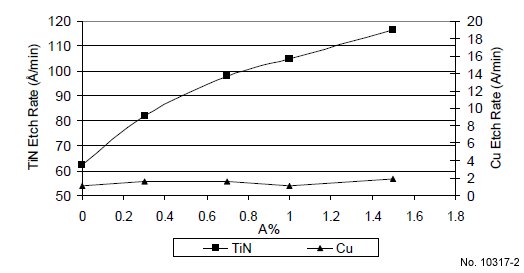

enhance TiN/Cu etch rate selectivity, another novel TiN etch

enhancement component, “compound B”, was added to a

formulation containing 1% of “compound A”. The resulting

TiN etch rate is increased with “compound B” concentration at

45 ºC as shown in Fig. 3. Fig. 2 and 3 show a low Cu etch rate

overall (<2Å/min), and that “compound A” and “compound B”

have no impact on Cu etch rate at 45 ºC.

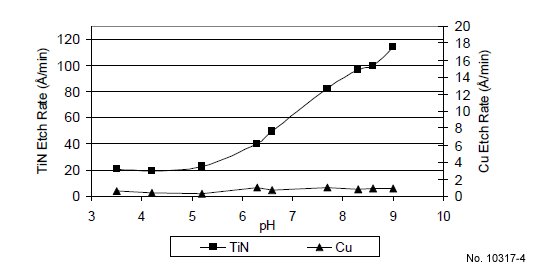

Fig. 4 shows the TiN and Cu etch rates versus pH at 45 ºC

for formulations containing 1% “compound A”. The TiN etch

rate increases with increasing pH because the etch rate is

directly related to HO2- species concentration. As the pH

increases, the concentration of HO2- also increases, resulting in

a higher TiN etch rate. Fig. 4 also shows that the TiN etch

rate can be tuned by simply adjusting the pH. To obtain a

constant TiN etch rate while maintaining H2O2 concentration

unchanged, it is important to keep pH unchanged. The Cu etch

rate remains very low (<2 Å/min) throughout the pH range

studied due to the presence of the copper corrosion inhibitor.

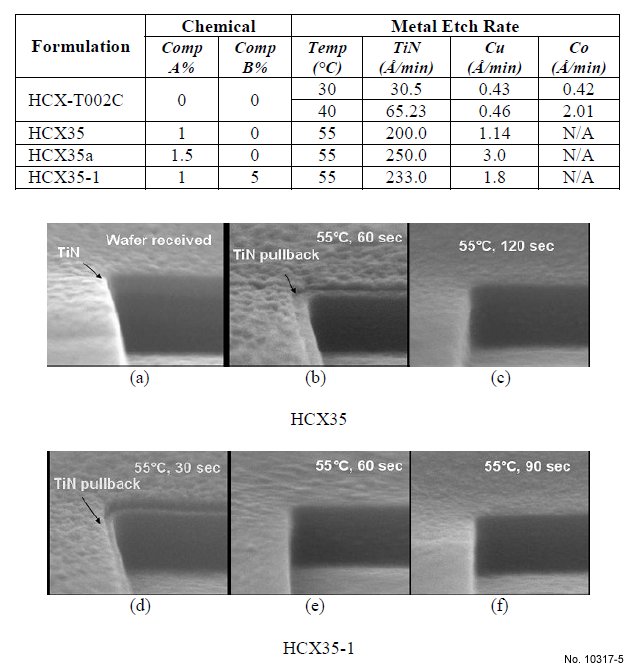

Metal etch rates of various formulations are shown in Table 1. By increasing process temperature from 30 to 40 ºC, the TiN

etch rate of HCX-T002C is increased from 30 Å/min to 65

Å/min. HCX35a with 1.5% “compound A” shows a higher

TiN etch rate (250 Å/min) vs. the TiN etch rate of HCX35

with 1% “compound A“ (200 Å/min), however, the Cu etch

rate is excessive for HCX35a, and the formulation is not

compatible with Cu. HCX35-1 with 1% “compound A” and

5% “compound B” shows a 233 Å/min TiN etch rate and a low Cu etch rate (<2 Å/min).

Fig. 5 illustrates (via SEM) two progressions of TiN

etching with process time at 55 ºC. In the first (Fig. 5 a-c),

HCX35 creates the TiN pullback after 60 seconds and complete

TiN removal after 120 seconds. In the second (Fig. 5 d-f),

HCX35-1 creates a significant TiN pullback after 30 seconds,

and complete TiN removal after 90 seconds. After 60 seconds

process time the TiN mask is almost completely removed by

HCX35-1 compared with HCX35 which shows only the TiN

pullback morphology in the same amount of time.

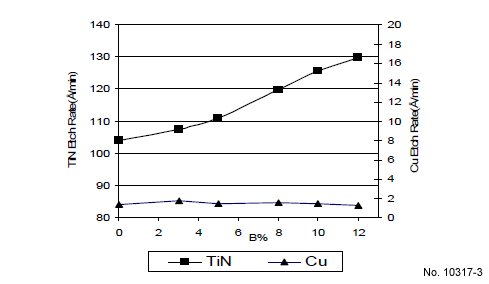

The effect of various formulations on the dielectric material

etch rates are shown in Table II, which highlights the low

impact of formulations on low-k, SiON and TEOS dielectrics.

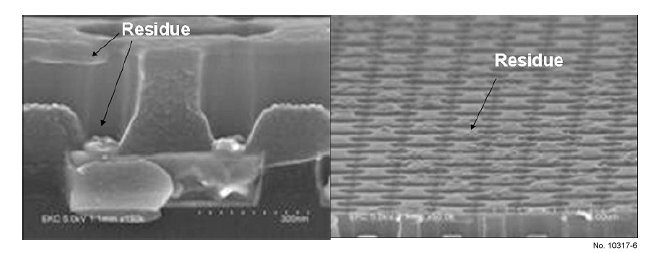

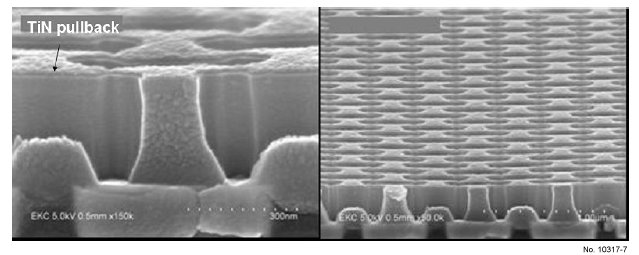

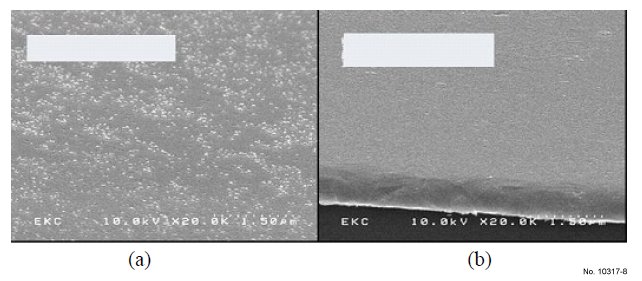

Fig. 6 shows the etching residues after dry etching using

TiN as an etching mask. Fig. 7 shows the complete removal of

these etching residues after treatment with HCX-T002C at

45ºC for 2 minutes, and also shows the TiN pulled-back

morphology.

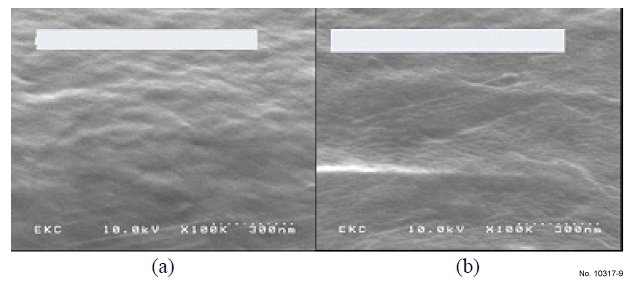

The SEM in Fig. 8 and 9 show the effect of the formulas on

copper oxidation. Fig. 8(a) shows that CuOx [3] was re-grown

after a 5 minute DIW rinse and dry. Fig. 8(b) and Fig. 9(a) and

(b) show that there are no CuOx formations after Cu was

treated with HCX-T002C, HCX35 and HCX35-1 respectively,

demonstrating that all three formulas have the ability to prevent

CuOx growth.

The formula, HCX-T002C, with a TiN/Cu etch rate

selectivity of more than 60 has been developed. The formula is

compatible with Cu, Co, low-k, TEOS and SiON dielectric materials and is able to remove all etching residues. This

formula prevents Cu oxidation during and after cleaning,

thereby relaxing queue-time restrictions between cleaning and

subsequent process steps.

HCX-T002C is ideal for applications that benefit from TiN

mask pullback morphology. HCX35 and HCX35-1

formulations with TiN/Cu etch rate selectivity greater than 200

have been developed. These formulations are compatible with

Cu, low-k, TEOS and SiON materials, and prevent Cu

oxidation during and after cleaning. The etch residue cleaning

performance of these formulations are currently under study.

Procedure (Condition): No data

Note: Formulations with TiN/Cu etch rate selectivity

greater than 60 at 40 °C for TiN pullback and 200 at 55° C for

complete TiN mask removal, respectively, have been developed.

The formulations are compatible with Cu, low-k and SiON

materials, and prevent Cu re-oxidation.

Reference: Hua Cui, TiN Metal Hardmask Etch Residue Removal with

Mask Pullback and Complete Mask Removal for Cu Dual Damascene Device, ASMC 2012, pp. 305-307.

Figure 1: TiN and Cu etch rate vs. H2O2 % at 30 ºC (pH: 9.2).

Figure 2: TiN and Cu etch rate vs. comp. A% at 45 ºC (H2O2 fixed,

pH: 8.8).

Figure 3: TiN and Cu etch rate vs. comp. B% at 45 ºC (H2O2 fixed,

pH: 8.8).

Figure 4: TiN and Cu etch rate vs. pH at 45 ºC.

Figure 5: TiN Etch SEM for HCX35 and HCX35-1.

Figure 6: Wafer SEM as received.

Figure 7: SEM after cleaning at 45 ºC, 120 sec (removed residues,

formed a TiN pullback).

Figure 8: Two Cu coupons with CuOx removed: (a) 5 min DIW rinse

only (b) Treated with HCX-T002C chemical at 50 °C for 2 min and then

5 min DIW rinse.

Figure 9: Two Cu coupons with CuOx removed: (a) Treated with

HCX35 at 55 °C for 2 min, then 5 min DIW rinse (b) Treated with

HCX35-1 at 55 °C for 2 min and then 5 min DIWrinse.

Table 1: Etch rate on various dielectric materials.