Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Nb - Dry Etching

Material Name: Nb

Recipe No.: 10321

Primary Chemical Element in Material: Nb

Sample Type: Bulk

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: The microwave cavity discharge system, capable of maintaining

discharges at pressures above 1 Torr. In the

microwave discharge, the high energy transfer efficiency

from the microwave electric field to the gas results in high

electron and high radical densities in the plasma. These

plasma conditions are more favorable for plasma etching

than for sputtering processes. Also, the higher gas

temperature in the plasma contributes to a higher rate of

chemical reactions and vaporization of Nb chlorides. The

Nb samples are placed in the quartz tube of a reaction

chamber. Low background gas pressure is achieved using

a system of mechanical and turbo molecular pumps, both

corrosive gas resistant. The gas in the reaction chamber

has high constant flow rates, so that reactive species lost

due to the chemical reaction can be replenished and

products of the chemical reaction removed away from the

sample. The gas flow control is achieved through flow

meters connected to a controller. For processes that

demand more than one reaction gas, a mixing chamber is

placed in front of the reaction chamber to facilitate a

better mixing of the gases. The experimental set-up is

connected to a spectrometer with the CCD camera for

emission spectroscopy measurements. Emission

spectroscopy is used as a process monitoring technique as

well as a tool to determine the reaction mechanism of the

plasma etching process.

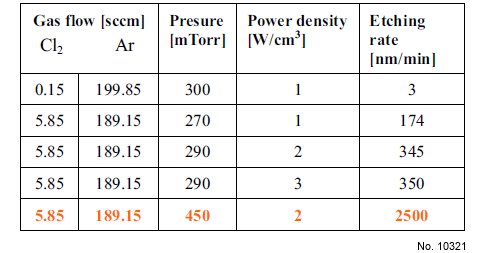

We determined the etching rates from the difference in

sample mass before and after exposure to Ar/Cl2

discharge. From Table 1, one can see that the etching rate

increases with a higher amount of Cl2 in the gas mixture.

The dependence of the etching rate on the reactive gas

concentration is an indicator of the chemical etching

contribution to the Nb removal mechanism.

Procedure (Condition): No data

Note: The preparation of the cavity walls has been one of the

major challenges in the superconducting radio-frequency

(SRF) accelerator technology. Therefore, constant

research and development effort is devoted to develop

surface preparation processes that will improve roughness

and lower the level of impurities, like hydrogen or oxygen,

embedded in bulk Nb, having in the same time reasonable

etching rates. Plasma based surface modification provides

an excellent opportunity to achieve these goals. We

present Ar/Cl2 discharge treatment of bulk Nb where we

achieved etching rates comparable to the rates obtained

with the electropolishing method without introducing

impurities in Nb. The current experiments were

performed on disk shaped Nb samples, exposed to plasma

produced in a microwave discharge system. Surface

composition and topology measurements were carried out

before and after plasma treatment. Upon determining

optimal experimental conditions on disk shaped samples,

we will apply the same procedure on the single cell

cavities, pursuing improvement of their RF performance.

Reference: M. Raškovic, et al., PLASMA TREATMENT OF BULK Nb SURFACE IN

THE Ar/Cl2 DISCHARGE, Proceedings of SRF2007, Peking Univ., Beijing, China, TUP: Poster Session I, pp. 323-326.

Figure 1: Experimental conditions and etching rates

obtained during plasma treatment of disk-shaped Nb

samples.