Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

GaAs - Dry Etching

Material Name: GaAs

Recipe No.: 10322

Primary Chemical Element in Material: Ga

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: All test wafers were taken as 3-inch S.I. GaAs wafers

with thickness ~650 µm. These wafers were then coated

within 30 µm thick positive photoresist AZ 4620 and exposed

to define circular holes with 70 µm diameter. The patterned

photoresist was post-baked at 120°C to improve plasma etch

resistance and adhesion. The patterned wafers were then

mounted on a carrier wafer with wax to make them loading

compatible with ICP system. This is necessary in view of the

fact that ICP etching requires cooling of the wafer during

etching, which is very difficult to achieve without carrier wafer.

GaAs wafers were then etched in standard ICP system,

one at a time. An oxygen plasma de-scum step prior to

etching was utilized in order to remove any residual

photoresist in the hole, which would have otherwise

contributed to the roughness of the etched surface. Plasma of

etcher is inductively coupled through a coil at 13.56 MHz,

with independent energy control provided by 13.56 MHz RF

biasing on the substrate. Helium gas was used to cool

backside of the wafer. The substrate temperature was set at

20 °C for all test conditions. The etch chemistry was a

mixture of Cl2/BCl3 through mass flow controlled process

gas lines. The chamber was evacuated to a base pressure of ~

9 x 10 exp(-6) Torr by a turbo-molecular pump backed by a dry

mechanical pump before initiating the etch process. The etch

gases mixture was introduced through an annular region at

the top of chamber lid. ICP etching was carried out using

positive photoresist mask to etch holes selectively. All the

etching runs were carried out through a design of

experiments by varying ICP power, process pressure,

Cl2/BCl3 flow rate ratio and chuck bias power. The etch rate,

etch depth, etch profile, mask selectivity and surface

morphology of etched features were determined by Scanning

Electron Microscopy (SEM). Deposition on the etched

sidewall was analysed by high resolution Energy Dispersive X-ray Analysis (EDAX).

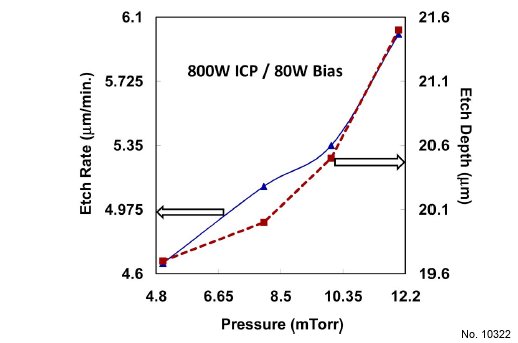

Effect of Pressure: Fig. (1) shows the variation of etch rate and the undercut

with the process pressure. The process pressure is varied

from 5 mTorr to 12 mTorr at a constant ICP power of 800W,

RF bias power of 8 0W and Cl2:BCl3 ratio of 4:1. It is seen

that the etch rate increases gradually from 4.6 µìm/min to

6 µm /min, when the pressure is raised from 5 mTorr to

12 mTorr. The increase in the etch rate with the pressure is

attributed to an increase in the concentration of reactive

chlorine species that enhances chemical component of the

etching. This suggests reactant limited regime at lower

pressures. In addition, it is evident from the figure that the

undercut also increases from 19.6 µm to 21.5 µm when the

pressure is increased from 5 mTorr to 12 mTorr. The reason

for the enhanced undercut can be understood as follows.

Actually the mean free path and plasma efficiency reduces as

we raise the pressure. This results in a reduction in sputtering

component on the etched surface. The decrease in sputtering

component with increasing pressure results in poor surface

morphology of etched surface with higher undercut. On the

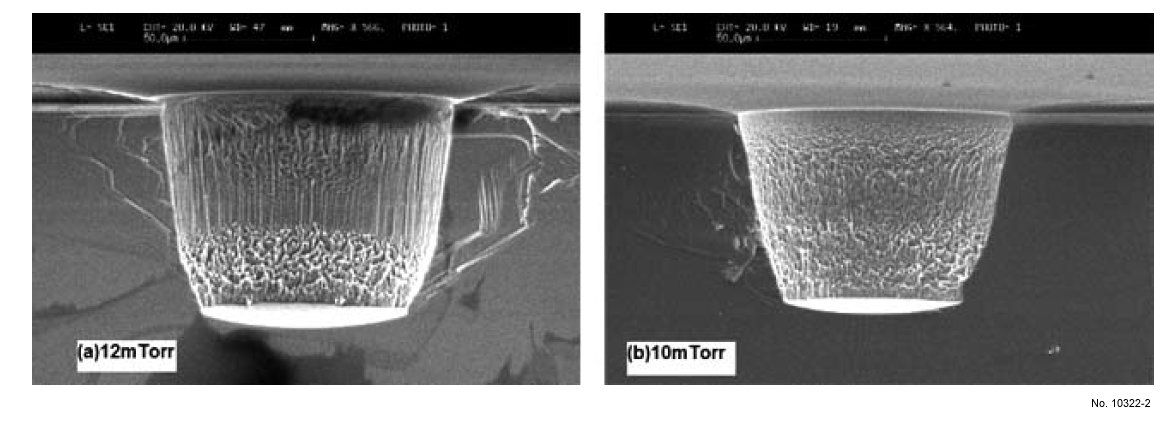

other hand, the etch profiles obtained at the pressure of

10 mTorr and 12mTorr under identical conditions are shown

in Fig. (2). It is clear from the figure that the better surface

morphology of etched surface is achieved at 10mTorr with

slight narrowing at the bottom of etched profile.

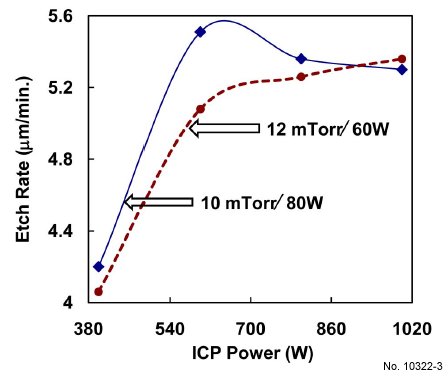

Effect of ICP Power: In Fig. (3), we show the variation of etch rate with ICP

power for two different pressures of 10 mTorr and 12 mTorr.

It is obtained here that the etch rate gets increased with the

ICP power up to 600 W at 10 mTorr pressure and 80 W RF

bias power, suggesting that the etching is limited by reaction

rate mechanism. This is attributed to higher concentration of

reactive chlorine radicals, which increase the chemical

etching component and hence ion flux that enhances the

bond breaking and sputter de-sorption efficiency of the etch

process. Further increase in the ICP power (above 600 W)

however leads to a relatively constant etch rate, which is

mainly due to competition between the sputtering and the

etch reaction as a consequence of increased ions that are

sputtering the adsorbed species (neutrals or ions) out of the

surface prior to etch reaction. This sputter de-sorption at

higher ICP powers results in etched surface with better

surface morphology at the same RF chuck bias power.

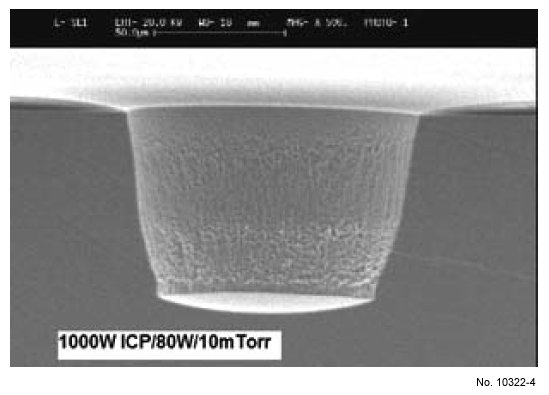

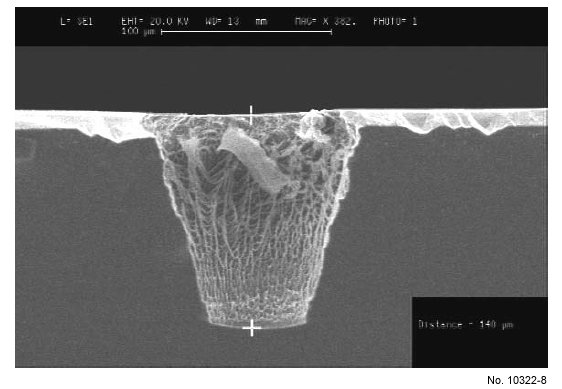

Fig. (4) shows the etch profile obtained at higher ICP

power of 1000 W, when the pressure is kept as 10 mTorr.

Under this situation, the etch profile with smooth etched

sidewalls is obtained. Fig. (3) also shows that the reaction

limited regime is enhanced up to 800 W with an increase in

the process pressure to 12mTorr at 60 W RF bias power.

Further, as the concentration of reactive species is increased

with pressure, their sputter de-sorption at 600 W is not

sufficient to remove active species. Hence, the etch rate is

found to saturate after 700 W up to 1000 W at 12 mTorr and

60W RF bias power.

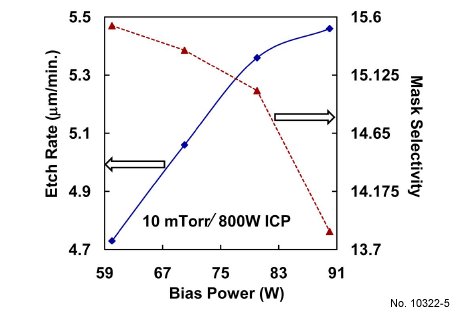

Effect of RF Bias Power: The dependence of etch rate and mask selectivity on the

RF bias power is shown in Fig. (5). It is clear from the figure

that the etch rate depends strongly on the bias power and it

gets enhanced rapidly from 4.73 µm/min to 5.36 µm /min,

when the bias power is increased from 60W to 90W. These

observations were made at 800 W ICP power, 10 mTorr

pressure and 4:1 as the Cl2:BCl3 ratio for 15 min as the etch

time. Enhancement in the etch rate is mainly attributed to

higher physical etching component at higher bias power due

to enhanced sputtering as a result of increased ion energy,

which improves removal of etch by-products and assists in

bond breaking. In addition, the etch an-isotropy is found

to enhance as RF bias power is increased. This is expected as

the ion energy gets increased due to the higher DC bias,

which leads to the straight sidewall profile of the etched

feature.

The GaAs: photoresist etch selectivity was determined by

the ratio of GaAs etch rates to photoresist etch rates. This is

portrayed in Fig. (5), where photoresist selectivity shows a

strong dependence on the RF bias and ICP power. Mask

selectivity is found to deteriorate from 15.53 to 13.85 when

the bias power is increased from 60 W to 90 W. This is

mainly caused by enhanced physical etching component at

higher RF biases. It would be worth mentioning that this is

one of the best reported selectivity using photoresist mask

for GaAs etching applications at low pressures. The increase

of resist etch rate with RF bias power and ICP power is due

to dominant physical etch mechanism. Actually larger RF

bias power increases the energy of ions bombarding the

wafer surface and the higher ICP power increases the density

or flux of the ions bombarding the wafer surface. Both of

these activities finally enhance the physical etch mechanism.

On the other hand, the reduced resist etch rate with

increasing pressure is mainly due to less physically and

higher chemically driven processes as a result of increased

reactant concentration at higher pressure.

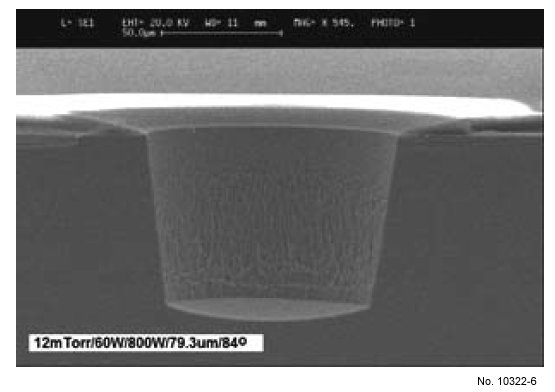

The desired etch profile with controlled side wall angles

and surface smoothness can be obtained with a proper

balance between enhanced sputter de-sorption of etch byproducts

and surface protection by by-products. The sputter

de-sorption of etch by-products is a function of ion energy

that depends upon pressure and ICP/bias power. Based on

above experimentation we arrived at a optimum recipe with

ICP power of 800 W, bias power of 60 W and pressure of

12 mTorr that resulted in etch profile with smooth surface

and controlled sidewalls with angle of ~84º, without

narrowing at the bottom, as shown in Fig. (6).

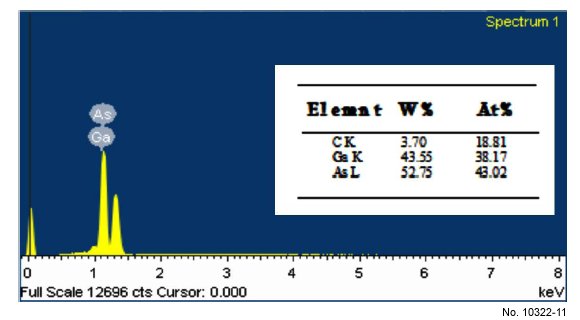

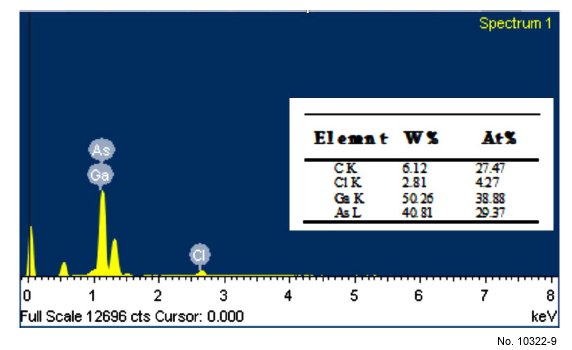

The straighter sidewall at the bottom is perhaps due to

the balanced chemical and physical etching components at

800 W ICP and 60 W RF bias. The EDAX spectrum of

optimum etched surface, as shown in Fig. (7), also indicates

negligible deposition of CClx polymer, most probably due to

a better balance between enhanced sputter de-sorption of

etch by-products and surface protection by by-products.

Moreover, the etched GaAs surface roughening is strain

induced, which tends to be more at defect sites due to

higher strain that leads to non-uniform etching.

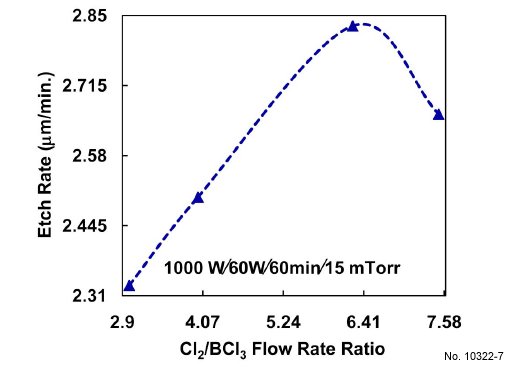

Etch Rate Variation with Cl2: BCl3 Flow Rate Ratio: Fig. (8) shows the etch rate variation with Cl2/BCl3 flow

rate ratio in ICP plasma for an etch time of 60 min at the

pressure of 15 mTorr. Here we observe that the etch rate is

increased from 2.3 µm/min to 2.7 µm/min as the flow ratio is

enhanced from 3 to 6.5. This is mainly due to an increase in

chlorine radicals with increasing percentage of Cl2 in gas

mixture that is responsible for chemical etching. Etch byproducts

staying on the surface block the fresh enchant

species from reacting. This saturates the etch process and

eventually leads to a reduction in etch rate at the above ratio

of Cl2:BCl3 as 6.5. In other words, above 6.5 ratio, reactant

limited regime dominates that reduces the etch rate. This

behavior suggests that the balance between physical etching

component and chemical etching component gets

deteriorated with the flow rate ratio, which degrades the

surface smoothness. On the other hand, the de-sorption of

chemical species limits the etching process at higher Cl2 flow

rates, leaving some of the residue on the surface itself.

This is shown in Fig. (9).

The EDAX spectrum of etched surface clearly indicates

the deposition of CClx polymer at high flow rates and

pressures (Fig. 10), which would have otherwise sputtered

away at low pressures due to higher ion energy.

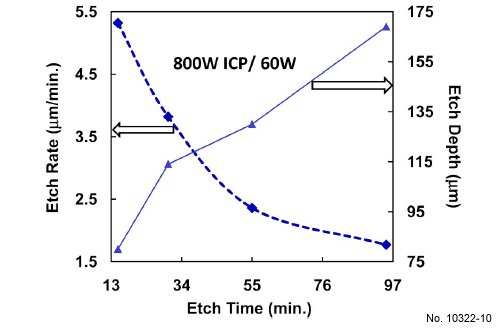

Effect of Etch Time: Fig. (11) shows the dependence of average etch rate and

etch depth on the etch time for ICP power of 800 W, 12 mTorr pressure and 60 W bias power. The average etch rate

is found to decrease with etch time, from 5.26 µm/min at an etch depth ~ 79..m to 1.71µm/min at an etch depth ~ 162..m.

This is mainly due to the reduction in the effectiveness of

supplying reactive species and removal of etch by-products

with increased depth. The etch rate reduction can be

compensated by increasing the gas flow rates and pressure.

However, this in turn results into deeper etch profiles with

severe by-product deposition on the sidewalls. This makes it

necessary to incorporate a polymer cleaning process for

deeper profiles after completion of etching step.

Procedure (Condition): No data

Note: GaAs etch characteristics like etch rate, etch profile sidewall angle, etch surface morphology and selectivity are

studied as a function of Inductively Coupled Plasma (ICP) power and Cl2/BCl3 flow rate ratio in ICP at low pressure

(<15mTorr) and low RF bias power (<100W) regime to achieve moderate GaAs etch rate with an-isotropic profiles and

smooth surface morphology. The low pressure regime etching at Cl2/BCl3 flow rate ratio of 4:1 has resulted in vertical

etch profiles with controlled sidewall angle ~84 deg., smooth surface morphology and good mask selectivity ~15 without

significant deposition of CClx polymer on the etched sidewalls but with limited etch depth ~ 100 µm using photoresist

mask. The mask selectivity is found to be a strong function of RF bias power and ICP power and a weaker function of

process pressure. The resultant etch depth increases with an increase in pressure and flow rate ratio at the expense of etch

surface morphology, as the desorption of chemical species limits the etching process at higher Cl2 flow rates and leaves

some of the residue on the surface.

Reference: D.S. Rawal, et al., A Highly Selective Low Pressure Inductively Coupled Plasma Etching

Process for GaAs Using Photoresist Mask, The Open Plasma Physics Journal, 2011, 4, 34-39.

Figure 1: Variation of etch rate and undercut with the pressure.

Figure 2: Etch profiles obtained under identical conditions at the pressure of (a) 12 mTorr and (b) 10 mTorr.

Figure 3: Variation of etch rate with ICP power.

Figure 4: Etch profile obtained at 10 mTorr pressure.

Figure 5: Dependence of etch rate and mask selectivity on RF bias

power.

Figure 6: Optimum etch profile with smooth surface morphology

and controlled sidewall angle of ~84º.

Figure 7: EDAX spectrum of etched surface at 12mTorr pressure,

800 W ICP and 60 W RF bias.

Figure 8: Etch rate variation with Cl2/BCl3 flow rate ratio at

15 mTorr/1000 W ICP/60 W RF bias.

Figure 9: Etch profile obtained at 15m Torr with Cl2= 125 sccm and

BCl3= 20 sccm flow rates and 1000 W ICP/60 W RF bias.

Figure 10: EDAX spectrum of etched surface at high gas flow rates.

Figure 11: Dependence of average etch rate and etch depth variation

on etch time.