Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

ZnSe - Wet Etching

Material Name: ZnSe

Recipe No.: 10329

Primary Chemical Element in Material: Zn

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Wet etching

Etchant (Electrolyte) Composition: The research was carried out using crystal wafers of

undoped ZnSe(I) (without thermal annealing), ZnSe(II) (after thermal annealing) and doped ZnSe(Al) and ZnSe(Te) crystals grown by the Bridgman method.

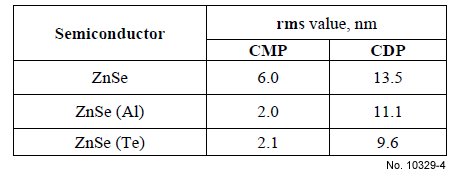

Chemical modification of the II-VI semiconductor

compounds surfaces is often carried out using bromine

containing mixtures. To obtain more perfect polished surface of ZnSe crystals, bromine containing

etching compositions such as Br2 in methanol or

ethanol with different bromine content has been used (Table 1).

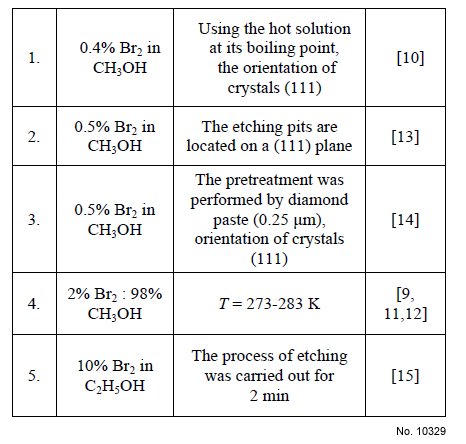

Mechanical polishing the samples. Polishing: ZnSe(I), ZnSe(II), ZnSe(Al), ZnSe(Te) plates after

cutting by our developed method should be performed

using abrasive powder with grain sizes M 10, M 5 and

M 1, or diamond powders ASM 28/20, ASM 10/7,

ASM 5/3, ASM 3/2, ASM 2/1 and ASM 1/0. The

polishing mixture is prepared in the form of abrasive

powders aqueous suspensions with distilled water. The

process should be carried out on a glass grinder,

alternately treating the plate with both sides within 1-

5 min by each abrasive (in order to decrease abrasive

grit) depending on the thickness of the damaged layer

that must be removed. After this, the samples should be

thoroughly washed with warm distilled water using the

addition of a small amount of detergent, then several

times with distilled water and dried in air. The

elimination rate of the surface layer was different

depending on the nature of these materials and abrasive

grit (Table 2). The ZnSe(Al) material elimination rate

was 6 µm/min when we made polishing by abrasive

diamond powders ASM 28/20, and by powder ASM 5/3

amounts to 4 µm/min. For ZnSe(Te) crystals the surface

layer elimination rate with abrasives ASM 28/20 is equal

to 18 µm/min and 2 µm/min with diamond powder ASM 5/3.

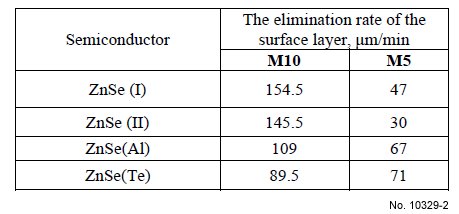

Chemical-mechanical polising: Elimination of the surface damaged layer should be carried out using the

CMP method. To make the CMP process for ZnSe(I),

ZnSe(II), ZnSe(Al), ZnSe(Te) samples, we developed

polishing solution at a volume ratio of components:

10 H2O2:10 HBr:80 EG characterized by small etching

and high polishing ability. We recommend holding the

etching mixture for 2 hours in order to achieve the

maximum concentration of free bromine, which is

formed during interaction of etching components. The

CMP process of wafers that are prepared in etching

solution with the rate 2 ml/min was carried out for 5 min

at T = 298 K using a cambric tissue covered glass

polisher, and CMP rate do not exceed 20 µm/min (Table 3).

Inter-cleaning the ZnSe surface after each stage

of treatment: After each stage of mechanical treatment

carried out surface inter-cleaning of undoped and doped

ZnSe single crystals should be made for removing dirt

from the surface of plates produced during cutting,

grinding and mechanical polishing. At first, to remove

the physical or mechanical contamination (dust, abrasive

particles, metallic materials and semiconductor crumbs,

which are formed during grinding) by rinsing in distilled

water with addition of surface-active substances.

Removing organic contaminants (grease, glue, residues,

suspension, and fingerprint) was conducted by

degreasing in organic solvents (ethanol, acetone), after

which the crystals should be thoroughly dried in flow of

purified air before the following technological

operations.

Procedure (Condition): No data

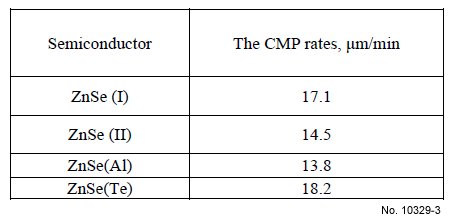

Note: The process of chemical polishing the undoped and doped ZnSe crystals

surface with H2O2 – HBr etchants has been studied. The dependence of the samples

polishing rate on the concentration of H2O2 in HBr solution has been investigated.

Surface states after chemical etching have been established using electron and atomic

force microscopies, and it was shown that the surface state is improved after chemical

etching. Etchant selection to develop slow polishing compositions for chemicalmechanical

polishing the investigated materials has been made. Concentration regions of

polishing solutions have been found for various types of ZnSe surface treatment: to

remove the damaged layer, to control the etching rate, to obtain samples of a given

thickness.

Reference: V.Ì. Tomashyk, et al., Optimization of conditions for treatment of ZnSe crystal surfaces

by chemical etching, Semiconductor Physics, Quantum Electronics & Optoelectronics, 2013. V. 16, N 2. pp. 140-145.

Table 1: The etchant compositions for chemical treatment

of ZnSe crystals.

Table 2: The elimination rates of ZnSe crystals surface

layer during mechanical polishing by free abrasives.

Table 3: The CMP rates of undoped and doped ZnSe

crystal surfaces.

Table 4: Surface roughness of undoped and doped ZnSe

after chemical treatment in the new bromine emerging

etchants.