Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

X-Cut Alpha Quartz - Dry Etching

Material Name: X-cut alpha quartz

Recipe No.: 10331

Primary Chemical Element in Material: Si

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: Experiments were performed using an STS320 RIE system

employing a liquid cooling system. The chamber pressure was

fixed at 20 mTorr, and the RF power was fixed at 300W5. This

led to a bias voltage which ranged from 650 to 700 V. The

target and the bottom plate were held at 15 C.

Etch targets were polished x-cut single crystal quartz

wafers provided by LapTech Precision and (where mentioned)

polished fused silica (amorphous SiO2) wafers provided by

Valley Design. All targets were segments of 1" discs or smaller

samples cleaved from 1" discs. Shadow masks for the argonconcentration

trials were 500 µm thick fused quartz wafers

with 8 mm by 2 cm central rectangular windows. Shadow

masks for the mask effect trials were 1 cm by 3 cm plates

0.3 to 1 mm thick made of fused silica, alumina, or Ni with

4mmdiameter holes through their centers. Etching gases were

SF6 and Ar, with total gas flow rate fixed at 18.3 sccm. All gas

percentages are in volume %.

Prior to etching, debris was removed from the surface of

thewaferswith a dry nitrogen gun, and all etch runs beganwith

a 5 min oxygen plasma clean (50 WRIE power, 300 mTorr of

chamber pressure) to remove residual organic contaminants.

In the mask effect trials, wafers were etched in individual

runs for 5.5 h with either no mask or one of the three possible

shadow masks using both 100% SF6 and 87.5% Ar (i.e.

12.5% SF6 by volume). Etch depth and surface roughness

were measured using both a contact and optical profilometer

(ZYGO New View). SEM images and energy-dispersive x-ray

spectroscopy (EDS) spectra were obtained with a JEOL-7000F

in secondary electron mode.

Wafers masked only by quartz were etched at several ratios

of SF6 to Ar to study the effects of the Ar concentration on

the etch rate and long-etch-time pitting. At 0%, 50%, 75%,

and 87.5% Ar these etches were carried out for much longer

times to obtain membranes of less than 20 ìmthickness. Long

etches with 50% Ar were also conducted on fused silica to

study the dependence of the pitting and etch rate on crystalline

microstructure, and conducted on x-cut quartz masked by Ni

to study the long-etch stability of this mask.

Procedure (Condition): No data

Note: In this paper we investigate the effect of Ar concentration and shadow mask material on the

etch rate, surface roughness, and micromask pit density and depth for reactive ion etching

(RIE) of x-cut alpha quartz. The ratio of SF6 to Ar is varied at constant power and pressure to

find an optimum Ar concentration for thinning x-cut quartz while maintaining good surface

quality. The recipe is used with an STS320 RIE system to produce smooth, through-hole-free,

insulating quartz membranes of 7 ìm thickness in selective locations on 100 ìm thick x-cut

quartz wafers. We demonstrate that surface quality is much improved by replacing at least

75% of the SF6 by volume with Ar, and that for non-inductively coupled plasma RIE the

standard mask material nickel is detrimental to surface quality for long etch times.

Reference: M D Minnick, et al., Optimum reactive ion etching of x-cut

quartz using SF6 and Ar, J. Micromech. Microeng. 23 (2013), pp. 1-7.

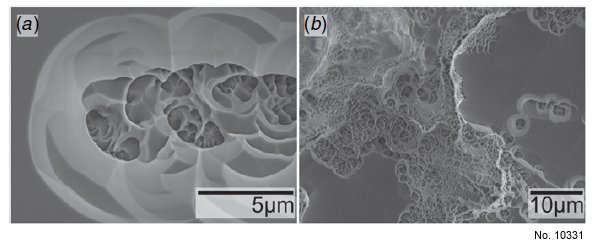

Figure 2: Deep pitting in quartz etched using 0% Ar (SF6 only) after

only 5.5 h (26.5 µm etch depth), (a) near the center and (b) near the

edge of the etch mask.

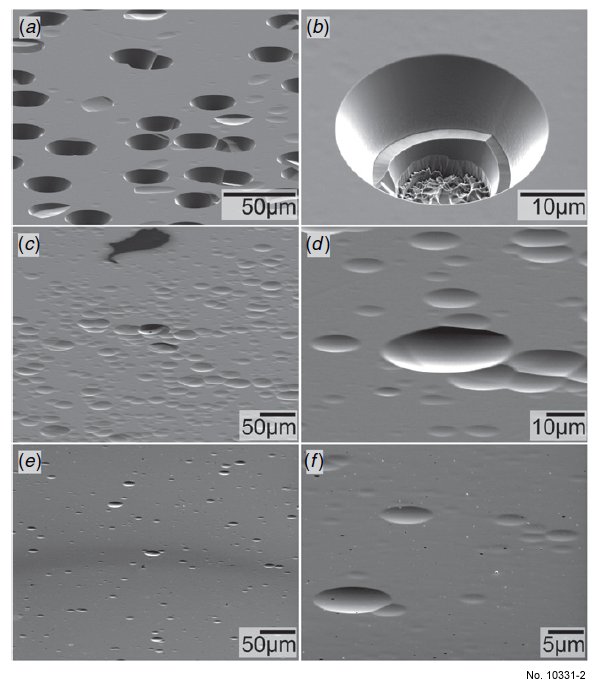

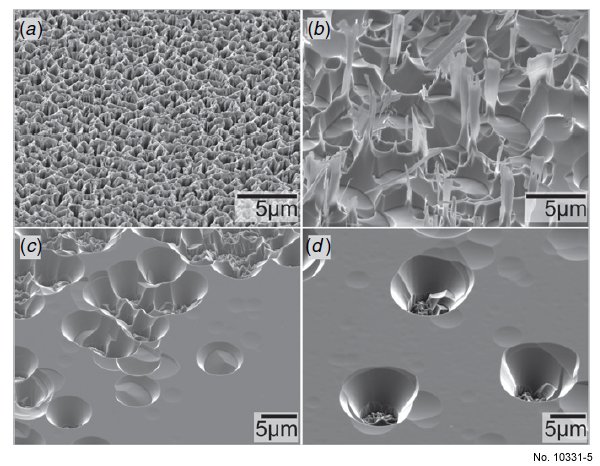

Figure 3: Reduced pitting after long etch times with increasing

Ar%: (a), (b) 50% Ar, 21.25 h (c), (d) 75% Ar, 29.73 h,

(e), ( f ) 87.5% Ar, 33 h. With 50% Ar, pit depth increases with etch

time and breaks through the thin membrane resonator as shown in

(b) (72.2 µm etched out of a 100 m wafer). 75% or more Ar did

not show a pit depth increase as the etch progressed and 87.5% Ar

showed even lower pit depth and density.

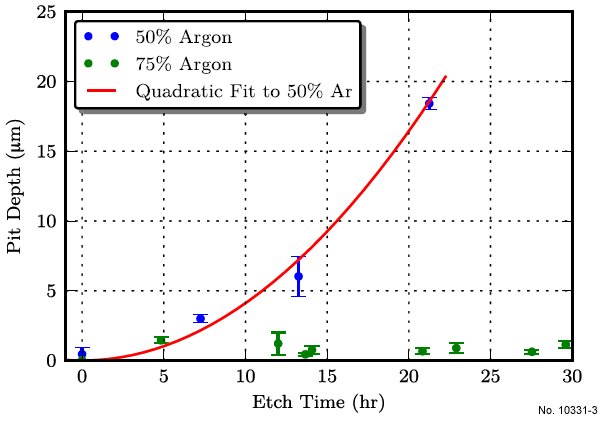

Figure 4: Pit depth versus etch time for 50% and 75% Ar. This plot

illustrates that pit depth increased as the etch progressed for 50% Ar,

but not for 75% Ar.

Figure 5: Results of etching fused silica with 50% Ar (50% SF6) for

21.25 h, depth of 97.4 µm, (a) typical center pit and (b) increased

pitting near the edge of the shadow mask. The smoother angles

observed, especially at the bottom of the pits, supports the

hypothesis that the crystal direction dependence of the etch rate is

responsible for the sharp-angle pitting when etching x-cut quartz.

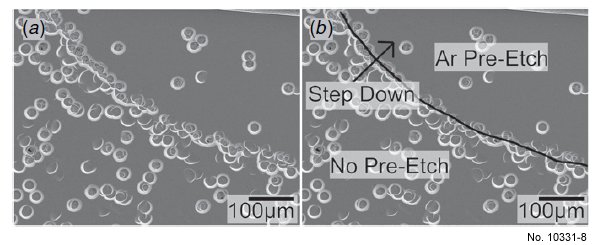

Figure 6: Reduced (but not eliminated) pitting from an extra Ar

pre-etch and a quartz ridge transformed into a curve of

densely-packed pitting, (a) clear and (b) annotated.

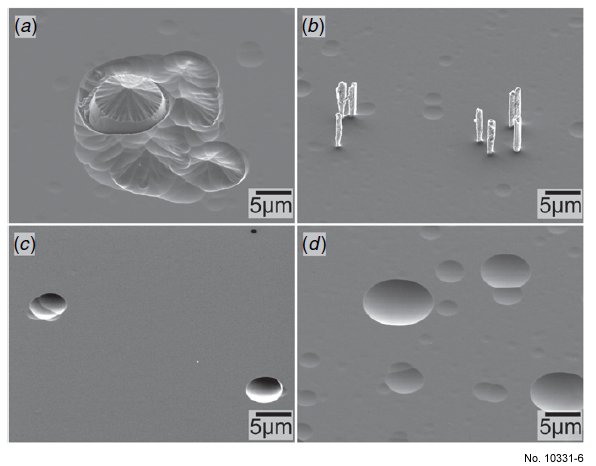

Figure 8: Surface of x-cut quartz after etching for 5.5 h with 100%

SF6 while shadow masked with (a) alumina, (b) Ni, (c) fused silica,

and (d) no mask. The quartz surface is not only etched far more

slowly with alumina as the shadow mask, but also greatly damaged.

Ni masking gave more pitting than silica masking and left residue

on the surface. Pitting with fused silica masking is similar to no

masking.

Figure 9: Surface of x-cut quartz after etching for 5.5 h with

87.5% Ar while shadow masked with (a) alumina, (b) Ni, (c) fused

silica, and (d) no mask. The shadow masking material has a much

smaller effect on surface quality when Ar is present in the etch gas.

The surface damage with an alumina mask is greatly reduced by the

introduction of Ar gas. Initial pitting is similar for Ni and quartz

masks but surface damage is still present for non-quartz masking. Ni

masking resulted in hollow column-shaped surface structures.

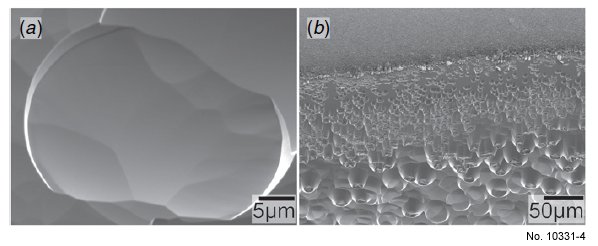

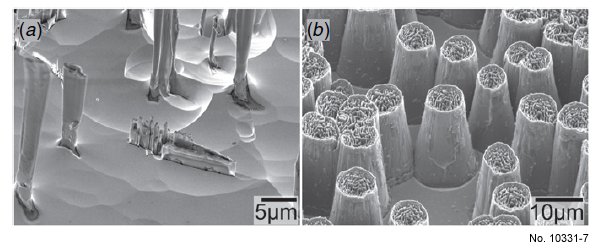

Figure 10: Structures observed on the surface for deep etching x-cut

quartz with Ni shadow masking using (a) 87.5% Ar and

(b) 93.75% Ar. Lowering the SF6 concentration reduces the lateral

etch rate and changes the structures from (a) hollow pillars to

(b) conical-shaped structures.br>