Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

TiN - Wet Etching

Material Name: TiN

Recipe No.: 10332

Primary Chemical Element in Material: Ti

Sample Type: Thin film

Uses: Etching

Etchant Name: None

Etching Method: Wet etching

Etchant (Electrolyte) Composition: Test vehicles consisted in HfO2/TiN film stacks deposited in 100 nm

deep nanotrenches and 200 nm deep cylindrical nanoholes.

Nanotrenches were etched in a 100 nm thick polySi film, using a 10 nm

SiO2 etch stop layer on a Si wafer. Trench CD was 31–35 nm, with a

pitch of 90 nm. Trenches were covered with 1.5 nm HfO2 and 25 nm

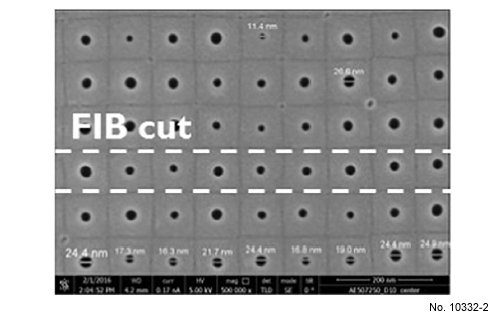

TiN deposited by ALD (atomic layer deposition). Nanoholes were

manufactured using a sacrificial nanopillars scheme. First 200 nm-tall nanopillars were etched in Si wafers

with a pitch of 90 nm and a diameter of about 40 nm, as described

in [6]. The diameter of the Si pillars was decreased by steam oxidation.

Then the space between the pillars was filled with silicon dioxide by

PEALD (plasma-enhanced ALD). The oxide overburden was removed by

a STI-like CMP stopping on the Si pillars. Finally, the Si pillars were

back-etched using a timed wet TMAH etch. The obtained nanoholes had

a top diameter varying from 11 to 27 nm, as shown in the SEM picture

in Fig. 2. Finally, the nanoholes were covered with HfO2/TiN films similarly

to the nanotrenches.

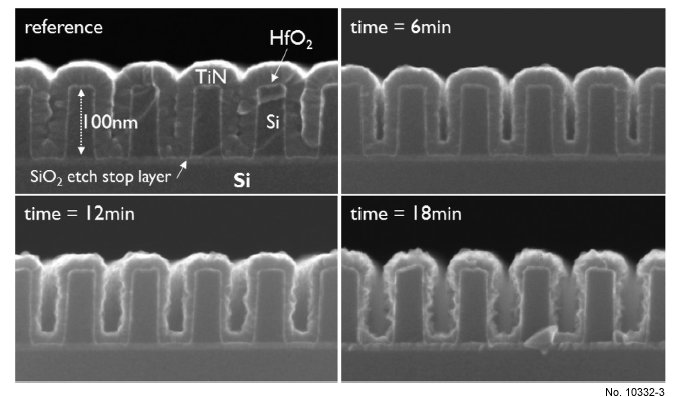

Etch tests were performed on coupons in beakers using APM 1:4:20

at 65 °C or room temperature (RT), adapting the etch rate to the layer

thickness to enable a kinetic analysis. To avoid any influence of the

presence of air-oxidized TiN at the surface of the TiN films on the results

of a kinetic test, a 2 min dilute HF (0.5%v) etch was performed at RT just before the APM etch.

Procedure (Condition): No data

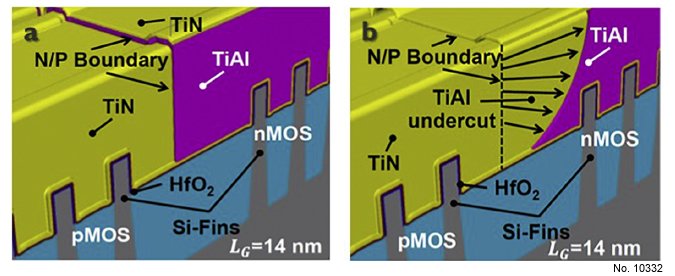

Note: In the manufacturing of multi-Vt FinFET transistors, the gate material deposited in the nano-spaces left by the

removed dummy gate must be etched back in mask-defined wafer areas. Etch conformality is a necessary

condition for the control of under-etch at the boundary between areas defined by masking. We studied the

feasibility of TiN etching by APM (ammonia peroxide mixture, also known as SC1) in nano-confined volumes

representative of FinFET transistors of the 7 nm node and below, namely nanotrenches with 1-D confinement

and nanoholes with 2-D confinement. TiN etching was characterized for rate and conformality using different

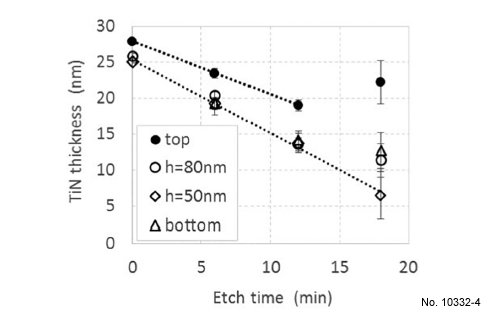

electron microscopy techniques. Etching in closed nanotrenches was conformal, starting and progressing all

along the 2-D seam, with a rate that was 38% higher compared to a planar film. Etching in closed nanoholes

proved also to be conformal and faster than planar films, but with a delay to open the 1-D seam that seemed to

depend strongly on small variations in the hole diameter. However, holes between the fins at the bottom of the

removed dummy gate, are not circular and do present 2-D seams that should lend themselves for an easier start

of conformal etching as compared to the circular nanoholes used in this study. Finally, to explain the higher etch

rate observed in nano-confined features, concentrations of ions in nanoholes were calculated taking the overlap

of electrostatic double layers (EDL) into account. With negatively charged TiN walls, as measured by streaming

potential on planar films, ammonium was the dominant ion in nanoholes. As no chemical reaction proposed in

the literature for TiN etching matched with this finding, we proposed that the formation of ammine complexes,

dissolving the formed Ti oxide, was the rate-determining step.

Reference: Guy Vereecke, et al., Wet etching of TiN in 1-D and 2-D confined nano-spaces of FinFET

transistors, Microelectronic Engineering 200 (2018) 56–61.

Figure 1: nMOS first process simulation of an N7 bulk FinFET. The shown cross-section is along a shared 14 nm gate at the n/p boundary after TiAl etch using either (a)

a fully anisotropic or (b) a fully isotropic etch. In (b) the n/p boundary undercut reaches the proximity of the first fin of the nMOS.

Figure 2: Top-down SEM view of nanoholes before HfO2 and TiN deposition,

showing the variability of holes' diameter and a FIB cut lamella for TEM inspection.

Figure 3: X-SEM of the nanolines test structure covered with 1.5 nm HfO2 and 25 nm TiN at different times of etching by APM 1:4:20 at RT after a 2 min dilute HF (0.5%

v) etch at RT.

Figure 4: Summary of TiN etch test on filled nanolines using APM 1:4:20 at RT,

showing the higher etch rate in-between nanolines as compared to the top.

Dotted lines are the linear regression lines for the data sets at top and 50 nm

above trench bottom.

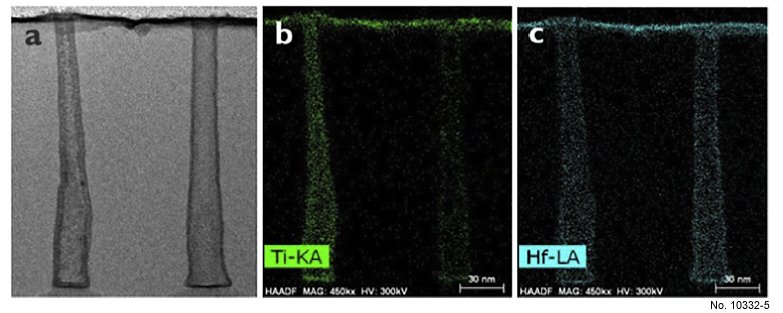

Figure 5: Pictures of nanoholes covered with 5 nm TiN on 1.5 nm HfO2 after 3 min etching in APM 1:4:20 at RT after a 2 min dilute HF (0.5%v) etch at RT: (a) TEM, (b)

Ti EDS map, (c) Hf EDS map. The diameters at the top were 12.6 nm and 15.3 nm, for the left and right hole, respectively.

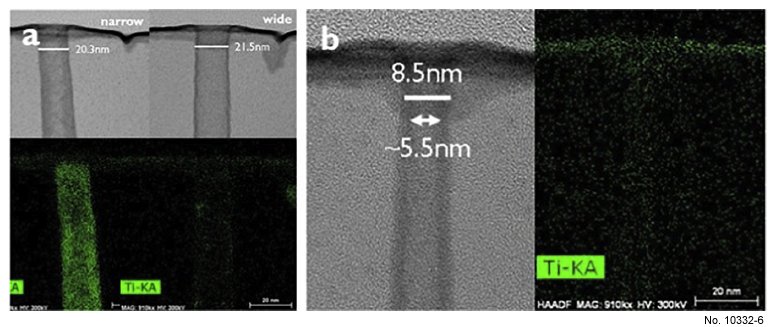

Figure 6: TEM pictures and Ti EDS maps of nanoholes filled with 10 nm TiN on 1.5 nm HfO2 after etching in APM 1:4:20 at 65 °C for 30 s (a) and 1.5 min (b), after a

2 min dilute HF (0.5%v) etch at RT.