Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Sub-Micrometer Trenches in Silicon - Dry Etching

Material Name: Silicon

Recipe No.: 10333

Primary Chemical Element in Material: Si

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

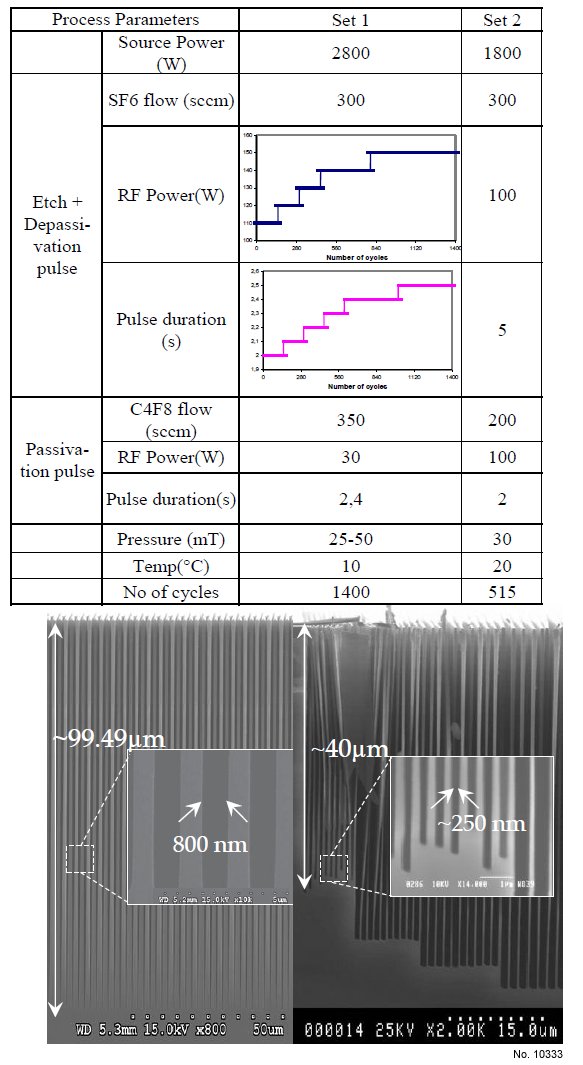

Etchant (Electrolyte) Composition: Bosch process etching: The basic Bosch process is a time-multiplexed plasma etch process typically involving three distinct steps that alternate - depassivation, etch and repassivation. Some steps maybe performed concurrently. To overcome the problem of excess bowing at the top of the trenches and of narrowing at the bottom, numerous etch trials accompanied by a detailed study of the relationship between the three etch steps were performed. The best etch profile was obtained using a two-step process in which the depassivation and the etching were

combined in one step. Since silicon etching takes place in this

case at a lower pressure than in the regular Bosch process, this

leads in a decrease of both etch rate and selectivity. Two sets

of experiments were performed with the optimized Bosch

process. Set 1constitutes simple trench test structures of 800

nm width, whereas Set 2 consists of trenches increasing in

width from 250 nm to 5ìm, with spacing of ~250nm between

them. Both were fabricated on standard <100> p-doped silicon

(Ultrasil – resistivity 0.01-0.015 Ohm x cm). The detailed etch

programs used for the two experiments are shown in Table 1,

and the obtained results are represented in Figure 1. Using the

Set 1 etching conditions in Table 1, 800 nm-wide trenches with

extremely vertical profiles and no bowing were manufactured,

reaching aspect ratios as high as 124:1 (Figure 1a). As feature

size decreases, achieving high aspect ratios becomes easier.

Being able to achieve a ratio of 124:1 on trenches as wide as

800 nm-wide trenches is therefore a challenge, requiring

dynamic adjustments of both the duration of the steps and of

the plasma power for Set 1. The previous HAR record of

107:1 was obtained on 374 nm-wide structures using Set

2 etch parameters, which, by extrapolating data from Figure 3,

would result in an aspect ratio of approximately 80:1 if

applied to 800nm structures. Using the Set 2 etch conditions

in Table 1, the highest aspect ratio was obtained for the 250

nm-wide trenches. The etch extended 40 µm in depth, resulting

in an extremely high 160:1 aspect ratio. The post-etch dicing

of the samples for the purpose of SEM observation resulted in

collapsed walls, as apparent in Figure 1b, however the

effectiveness of etch is apparent from the regular square

profile at the bottom of the trenches, which also suggests that

even higher aspect ratios might be possible by further etching.

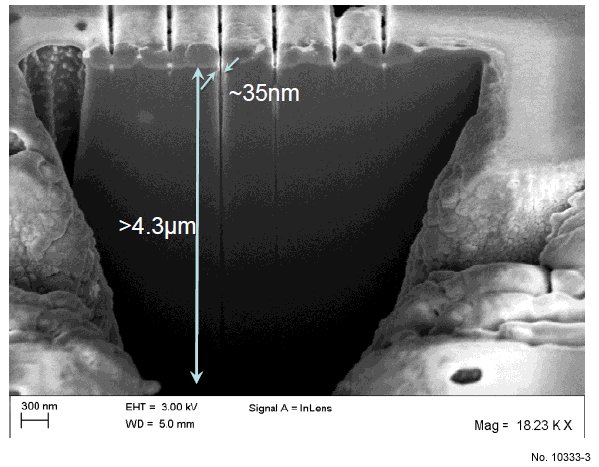

Cryogenic DRIE: By comparison with the Bosch process, cryogenic DRIE

offers the benefit of producing highly vertical sidewalls with

no scalloping effect, which are of great s ignificance when

etching sub-micrometer structures. This is a consequence of

the process being carried out at extremely low temperatures,

and results in reduced isotropic etching of silicon.

The challenge in case of cryogenic etches is to use a suitable

mask that will resist at such temperatures and that can be

patterned at sub-micrometer length scales. For the final set of

experiments performed in this work (Set 3), we used a

combination of focused ion beam (FIB) etching and cryogenic

DRIE to achieve HAR trenches with widths in the tens of

nanometers range. The FIB was used to pattern lines of 35+/-

10 nm width and 500 nm spacing on a 70 nm-thick aluminum

film. This created a hard mask for the subsequent etching,

which used the process parameters shown in Table II. Figure

2 shows the corresponding SEM results, indicating that aspect

ratios of >125:1 could be achieved. We also note that the FIB

was used again, before the imaging, to etch a vertical

rectangular hole that exposes a partial cross-sectional view of

the etching. We would like to explicitly mention that these are

preliminary results and that further work is ongoing.

Procedure (Condition): No data

Note: This paper focuses on Deep Reactive Ion Etching (DRIE) of sub-micrometer features. Very high aspect ratios up to 160:1 on trenches of 250 nm have been achieved using the Bosch process and 120:1 on 35 nm-wide trenches using a cryogenic process. The proposed etch recipes are specifically optimized for sub-micrometer features, and are not compatible with feature sizes in the tens of micrometer range. Based on analyzing data from our experiments and from literature, we show that a previously reported two-parameter empirical logarithmic law accurately describes the dependency of aspect ratio on trench width over a wide range of widths and etch parameters, including the sub-micrometer regime. We also propose a new figure of merit that describes the ultimate aspect ratio achievable for any given etch process.

Reference: Jayalakshmi Parasuraman, et al., Very High Aspect Ratio Deep Reactive Ion Etching of Sub

micrometer Trenches in Silicon, JMEMS-2012-0181, pp. 1-4.

Figure 1 + Table 1: Table 1: Parameters for deep etching of sub-micron features. Figure 1: HAR structures manufactured using the Bosch process: (a) 800nmwide

trenches with a depth of 99.5 µm (aspect ratio 124:1) and (b) 250 nm - wide trenches with a depth of 40 µm (aspect ratio 160:1). Some of the walls

collapsed during the dicing procedure.

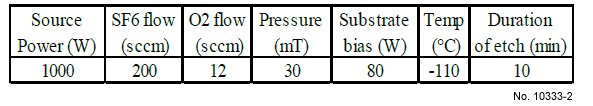

Table 1: Process parameters for the cryogenic etch process (Set 3).

Figure 2: SEM image of ~35 nm trench etched to a depth greater than 4.3 µm,

hence with aspect ratio >125:1. A rectangular hole was etched using the FIB

to allow cross-sectional visualization.