Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Tellurium Dioxide (TeO2) - Dry Etching

Material Name: Tellurium Dioxide

Recipe No.: 10334

Primary Chemical Element in Material: Te

Sample Type: Layer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

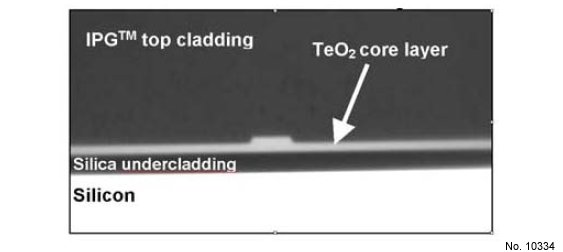

Etchant (Electrolyte) Composition: The final etching conditions were 30 sccm H2, 5 sccm CH4, 30 sccm Ar, 30 mT pressure,

150W RF power, and the rib was etched 0.8 microns deep. Post etch resist removal was

accomplished by an oxygen plasma strip to avoid damaging the TeO2 surface. The

waveguides were then clad with a 15 µm thick film of UV cured inorganic polymer glass

(RPO Pty Ltd, IPG) which has a refractive index of 1.509 at 1550 nm. End facets were then

hand cleaved on the waveguides with a diamond scriber. The resulting waveguide chips were

7.8 cm long.

Procedure (Condition): No data

Note: We report on the fabrication and optical properties of the first

very low loss nonlinear Tellurite planar rib waveguides ever demonstrated.

A new reactive ion etch process based on Hydrogen as the active species

was developed to accomplish the low propagation losses. Optical losses

below ~0.05 dB/cm in most of the NIR spectrum and ~0.10 dB/cm at

1550 nm have been achieved - the lowest ever reported by more than an

order of magnitude and clearly suitable for planar integrated devices. We

demonstrate strong spectral broadening of 0.6 ps pulses in waveguides

fabricated from pure TeO2, in good agreement with simulations.

Reference: S. J. Madden, K. T. Vu, Very low loss reactively ion etched Tellurium

Dioxide planar rib waveguides for linear and non-linear optics, 28 September 2009 / Vol. 17, No. 20 / OPTICS EXPRESS 176450-17651.

Figure 1: Optical micrograph of cleaved finished waveguide in the 1.6 µm thick Tellurite film.