Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

3D Charged Particle Trap - Dry Etching

Material Name: Silicon

Recipe No.: 10335

Primary Chemical Element in Material: Si

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: An Oxford Plasmalab 100 machine (Oxford Instruments

plc, Abingdon, Oxfordshire OX13 5QX United Kingdom)

was used for DRIE. The machine has RF plasma power of up

to 30 0W at 13.56 MHz, ICP power of up to 3000 W at

13.56 MHz, and a substrate temperature range from -150 to 400 C. Helium flows across the back side of the wafer at

2–10 sccm to maintain a constant pressure of 10 Torr. The SF6 flow ranges from 50 to 300 sccm, while the O2 flow rate

ranges from 5 to 40 sccm. For RIE, a South Bay Technology RIE 2000TM was used. It has an RF power range of 0–20 0W at a frequency of

13.56 MHz. It can reach a base pressure of 1 x 10 exp(-5) Torr and offers highly anisotropic etching with minimal undercutting.

Photoresist mask for silicon dioxide etching: A 0.004-mm oxide layer was grown thermally on Si

(front and back) by using a wet oxidation method. The hole pattern was transferred to the wafer using the photolithography

process described previously. Wet etching of an oxide resulted in an undesirable oxide

profile at the hole edges, as shown in Fig. 6. The AZ5214TM

photoresist (Clariant Corp., AZ Electronic Materials) was

ultimately used as the mask. The exposed oxide was etched in a buffered oxide etch solution.

Several different photoresists were tried as masks for

oxide etching, including AZ5214 (Clariant Corp.), SU8

2025TM (MicroChem Corp.), PR1-4000ATM (Futurrex,

Inc.), and SU8 2010TM (MicroChem Corp.). AZ5214 and

PR1-4000 A, being positive photoresists, had poor RIE selectivity

and developed poor sidewall profiles. These two

materials were not used as oxide etch masks. SU8 2025

photoresist is widely used for MEMS applications because

of its robust nature. This photoresist develops with vertical

profiles and has high selectivity to oxide. Better results

were obtained using SU8 2025 in RIE, but other problems

arose. SU8 2025 is a highly viscous photoresist and often

formed bubbles when applied to the wafer. These bubbles

had to be removed by using a pipette. We finally used SU8

2010, which has a much lower viscosity than SU8 2025. It

was easier to remove the bubbles from this photoresist

while maintaining high oxide selectivity during the RIE process.

During photolithography with the SU8 photoresist, we

also used OmniCoatTM by MicroChem, which allowed easy

stripping of the SU8 photoresist after the oxide mask had

been etched in the RIE process. OmniCoat was spun on the

wafer at 2000 rpm for 30 s and then baked at 200 C on a

hotplate for 1min. Then, the SU8 layer was spun on top of

the OmniCoat layer at 2000 rpm for 30 s. This wafer was

then baked on a hotplate at 65 C for 1 min, followed by a

2-min bake at 95 C. However, the spinning of SU8 2010

led to the formation of edge beads. These edge beads were

thicker and took more time to treat than a thinner and more

uniform layer of SU8. The edge beads adhered to the glass

mask when it was pressed against the wafer during the UV

exposure step. To prevent this, the baking time was

increased to 2.5 min at 95 C. This cured the edge bead

problems.

The problem of bubbles in the viscous SU8 2010 also

caused issues in Si etching. During photolithography, these

bubbles exposed the oxide to RIE, and they were consequently

etched in DRIE. Because larger features etch faster

in DRIE, the bubbles that were larger than 0.1 mm etched

through the wafer faster than the desired 0.1 mm holes. This

problem was solved by using SU8 2005, which is less viscous

than SU8 2010. The SU8 2005 was spun at 1000 rpm

for 30 s and was then soft baked at 65 C for 2 min and at

95 C for 5 min. The SU8 was then exposed to UV light

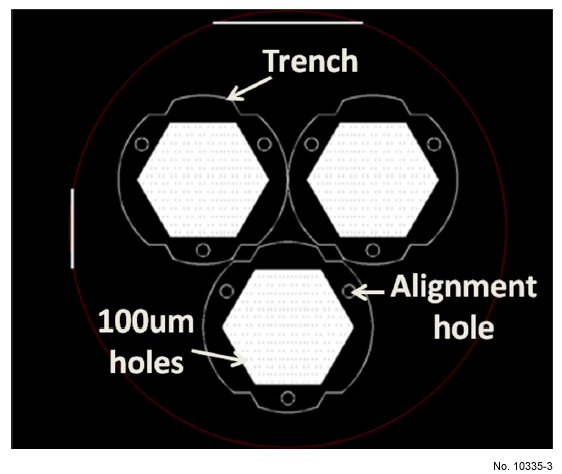

through the glass mask shown in Fig. 3.

SU8 is a negative photoresist, and thus, we used a mask

opposite to that shown in Fig. 3. The mask was mostly transparent,

while the holes and trenches were opaque. An SU8

layer ~0.010 mm thick requires 110–140 mJ/cm2 of energy

from the UV lamp, according to the product datasheet. A

postexposure bake was then performed with 2min of baking

at 65 C, 3 min of baking at 95 C, followed by another

minute of baking at 65 C. Finally, the wafer pattern was

developed by immersion in the SU8 developer, for 3min for

SU8 2010, and then 2 min for SU8 2005. The exposed oxide

areas were then ready to be etched by RIE.

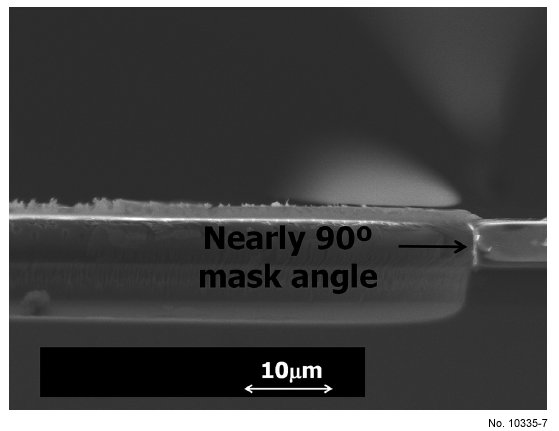

The following were the optimal RIE parameters for

oxide etching with a SU8 2010 mask: pressure=150 mT, RF power=150 W, CF4 flow=30 sccm, O2 flow=2 sccm,

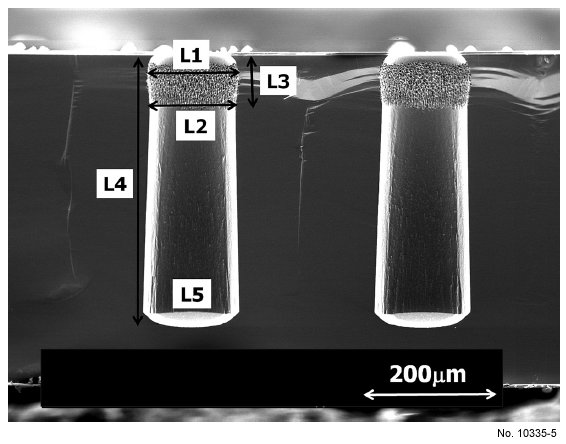

and duration=1 h.The results of the oxide etch are shown in Fig. 7. The image shows that some of the silicon was also etched during

RIE. This overetching was reduced by simply shortening the etch duration.SU8 was stripped by immersing the wafer in Remover

PGTM heated at 100 C for ~20 min.

Masks for Si etching: Both negative and positive photoresists used in throughwafer

deep etching tend to crack at cryogenic temperatures.

Silicon oxide is a commonly used hard mask for cryogenic

etching and has been used heavily in this research. Metal

masks were also used in this research but were found to be not

quite ideal, although they have a much higher selectivity.

We used a chromium (Cr) thin film metal hard mask

because of its higher selectivity to silicon in DRIE. Also,

growing 0.004 mm of oxide by oxidation can take up to 5

days, while metal film sputtering takes only a few hours. We

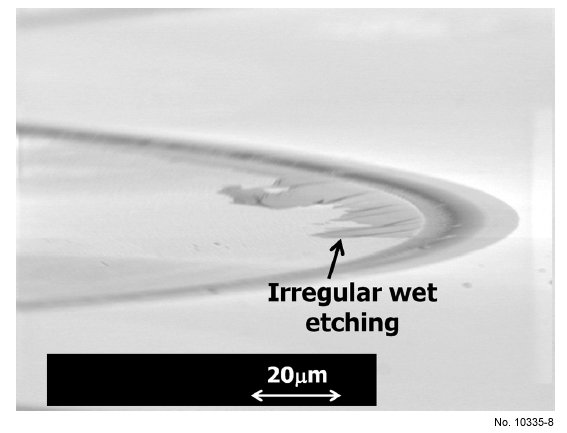

performed wet etching of a Cr film and the results were not

uniform, with irregular Cr pieces found in many places.

These irregularly shaped metal masks led to nonuniform

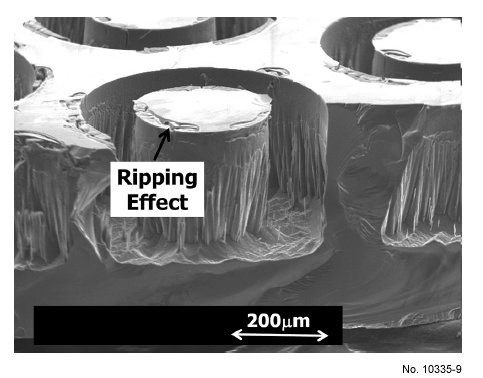

etching of Si around the feature boundaries, as seen around

the hole top and the island in Fig. 8.

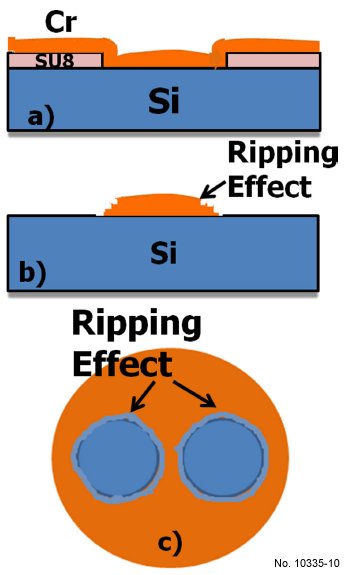

There were also unsatisfactory results when using the Cr

lift-off process instead of the Cr wet etch. This was because

of a thin metal film on top of the photoresist, which came

into contact with the metal layer during deposition. This

caused a ripping effect during lift-off, as shown in Fig. 9 and

explained schematically in Fig. 10. This effect resulted in a

rough edge on the metal hard mask in Fig. 9 (the holes

shown in this figure were from an early mask design with

0.5-mm-diameter holes). These rough edges created undesirable

distortions in the hole profiles.

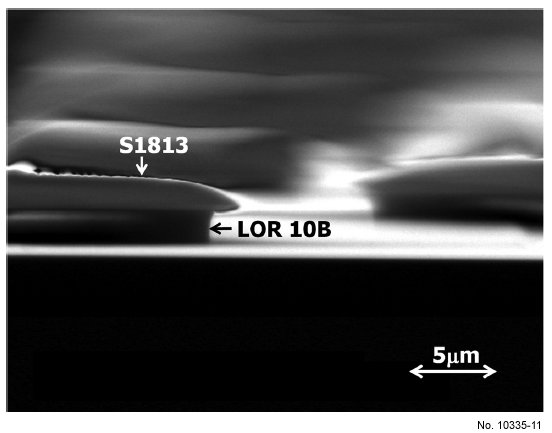

To reduce this ripping effect, we used a bilayer lift-off process

by MicroChem Corp. Lift-Off Resist (LOR 10BTM) is a photoresist composed of a 0.002-mm sublayer below another

positive resist, S1813TM, as shown in Fig. 11. This sublayer

produced a gap between the metal on the photoresist and that

on the wafer, which resulted in clean edges during the lift-off

process.

We used a wafer with a Cr mask and LOR bilayer lift-off

for deep reactive ion etching. In the wafer holes, we noticed

similar levels of bowing to those produced with the oxide

hard mask wafers. These metal masks accumulated negative

charges, which led to the deflection of ions, causing bowing

near the hole tops.

The oxide mask was deemed to be superior because of

the simplicity of the patterning process and because of the

mask’s ability to keep the DRIE chamber free of contamination.

It also prevented unwanted materials from being in the

final trap. Ultimately, purchasing Si wafers with 0.004 mm

oxide layers reduced the time spent on the basic task of Si

wafer wet oxidation.

In choosing between oxide and metals for the hard mask

materials, it was found that the metal masks displayed a

micromasking phenomenon. In the literature, they have been

shown to be an inappropriate material for clamping rings because they become polarized in active plasmas because of

their high conductivity. Self-sputtering led to the local transfer

of small amounts of metal atoms on the wafer, causing micromasking

of the silicon that affected the etch process.

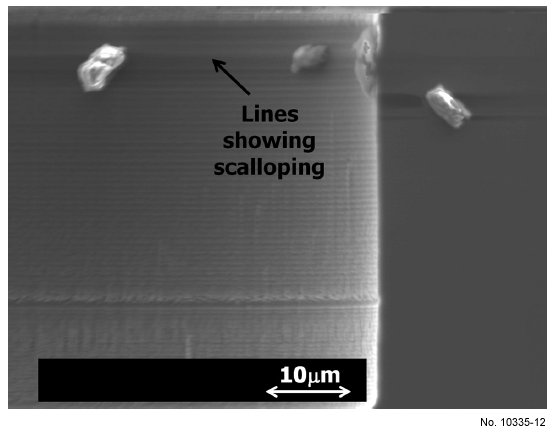

Selection of an etching technique for DRIE: Both the Bosch and cryogenic DRIE processes were

tested on the wafers, but the cryogenic version was chosen

over the Bosch process because of the following negative

characteristics of the Bosch process:

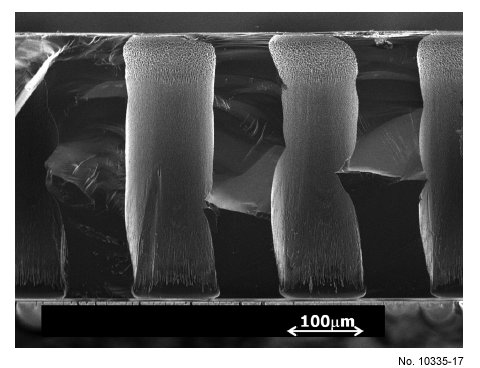

(1) It produced scalloping on the sidewalls (i.e., lines in

saw-tooth form) because of the alternating etching and

passivation cycles that are characteristic of this process.

An example of scalloping is shown in Fig. 12. Smooth

wafer sidewalls are required for the trap operation.

(2) It has low selectivity between the oxide and Si. A thicker

hard mask would be required to etch the holes completely

through 0.5 mm of Si.

(3) Metal masks like Cr and Al can be used for the Bosch

technique, but they have some disadvantages. As discussed

earlier, the metals exhibit a micromasking phenomenon

caused by the self-sputtering of the metal

films. The lift-off process for metal masks is challenging

because in the Bosch process, the feature size depends

largely on the LOR development time. Further calibration

of the development time is required to obtain better

feature size resolution. Metals can also act as contaminants

in the DRIE chamber and the positron traps.

Therefore, Al masks cannot be used in the Bosch technique

to solve the low selectivity issue between oxide

and Si.

(4) The Bosch process creates a fluorocarbon polymer during

the passivation cycle. This polymer forms a layer

inside the ICP tube and the DRIE chamber. This can produce

random changes in the etch rates and the etching

angles.

(5) If cryogenic and Bosch etching are performed alternately,

the DRIE chamber must be cleaned after each

etch. The chamber has to be heated from ~95 C to

room temperature and brought up to atmospheric pressure.

This wastes valuable resources, including liquid

nitrogen and time.

DRIE method selection: Effects of temperature,

pressure, ICP, RF power, gas flow, and O2 gas

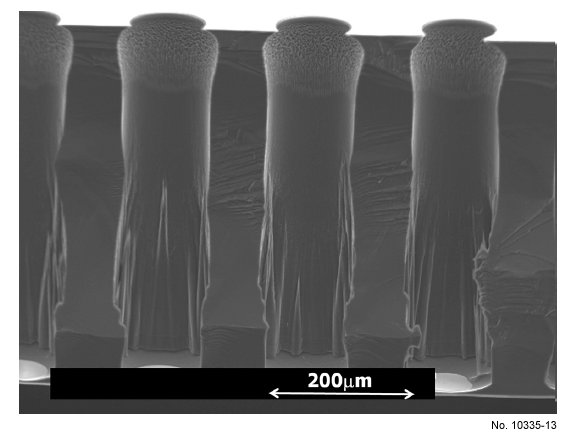

percentage on the etching results: Initially, the etching we carried out was based on a method

suggested by Craig Ward of Oxford Instruments. We optimized

his method to produce nearly vertical, smooth sidewalls with

minimum amounts of bowing and crystallographic effects. A

base reference method was achieved for future comparison.

This etch method had a process temperature of ~95 C, pressure

of 12 mTorr, total gas flow of 76 sccm (SF6 ž O2), O2 percentage

of the total gas flow of 7.9%, RF power of 3 W, and

ICP power of 700 W. Figure 13 shows an SEM image of a hole

profile produced while using these etch variables.

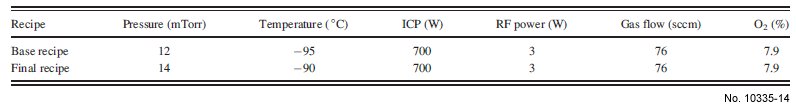

After this base result was established, each parameter was

altered while observing the resulting changes in the hole profile.

Major changes were observed in the hole profile with

increases in chamber pressure and temperature, as shown in

Table 1.

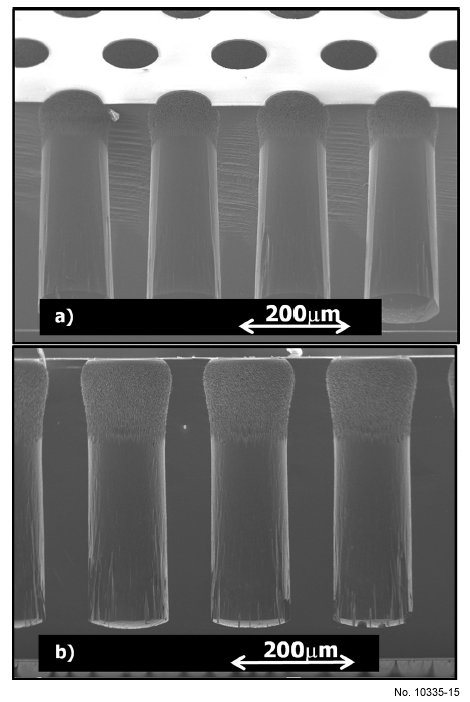

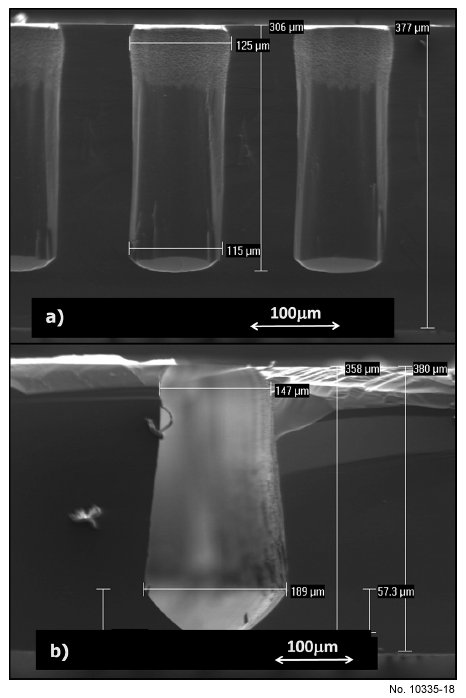

As shown in Fig. 14, a higher pressure (14 mTorr)

removed the sidewall roughness and a higher temperature

(~90 C) produced straighter sidewalls (89.8 deg.). Both parameters

were chosen for the final method. This method results

in high aspect ratios for the through-wafer holes with smooth

and near-90 deg. sidewalls.

Figure 15 shows a sample image of the final results when

using the new variables. A small amount of bowing has been

deemed acceptable for trap construction and can be removed

by grinding and polishing. With this final method, holes

were etched through Si wafers and the process has been

reproduced. Etched dies were later stacked axially and

bonded using a thermocompression bonding technique.

These bonded dies allowed the fabrication of one section of

the trap assembly process.

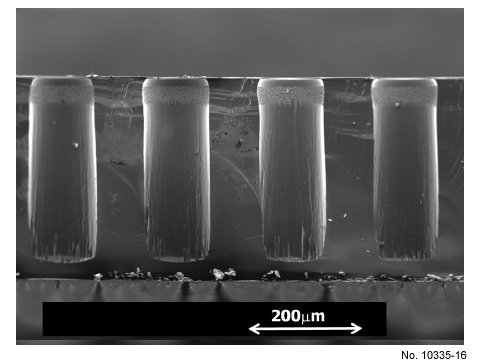

Challenges of cryogenic DRIE through-wafer etching: Several of the complications and issues faced during the

etching of anisotropic, high aspect holes in silicon wafers were associated with use of DRIE at cryogenic temperatures

with an oxide hard mask. These problems were addressed by

changing the process parameters of the DRIE machine. The

issues encountered in this research were bowing, notching,

undercutting, crystallographic plane features, variations in wafer

thickness, DRIE plasma variations, and contamination issues.

Bowing: Bowing is the convex sidewall shape near the hole top

shown in Fig. 16. Boufnichel et al. attributed bowing to

the multiple reflections of ions with incident trajectories that

were not normal to the wafer surface and deflection of ions

on the mask side slopes, which then sputter the passivation

layer at the top. Radicals penetrate through voids created in

the SiOxFy layer and assist the ions in the destruction of the

hole profile. Changing a few of the process parameters

enabled reduction of the bowing effect. When stacking and aligning hundreds of Si wafers axially, it is desirable to have

straight and identical sidewalls in all wafers, without any

deformations in their profiles. Another solution to remove

the bowing effect is to polish off the top of the wafer.

Notching/footing: Notching and footing occur at the bottom of the etched

hole and the ions affect the oxide at the wafer back. The oxide

is a nonconducting material that accumulates negative charges

on its surface and leads to the deflection of the positive ions in

the plasma. These deflected ions start etching into the Si walls

at the bottom of the hole, as shown in Fig. 16. It may be possible

to prevent notching by using a conducting material at the

bottom of the wafer, so that the conducting material will not

accumulate a charge and deflect the ions. To test this hypothesis,

aluminum (Al) was deposited on the back side of a wafer

as an etch stop, but the Al layer, being only 0.0005 mm thick,

started breaking away faster than the oxide. Also, the thermal

conduction was better on the Al etching surface than on the

oxide, which changed the hole profile. The crystallographic

effect appeared at the bottom of the holes. If the Al backing

remained, the table temperature would need to be increased

by at least 10 C to stop the crystallographic angles (which are

explained later in this section) forming at the hole bottom.

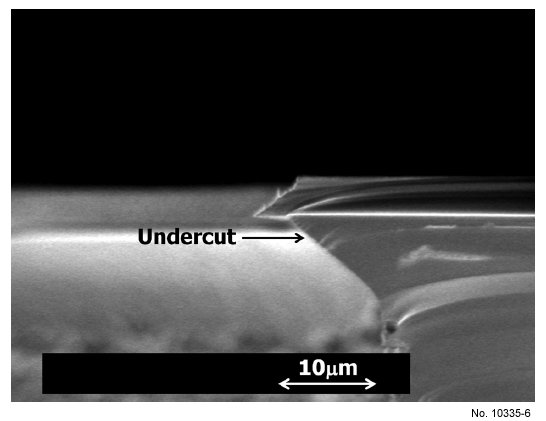

Undercutting: Undercutting is caused by the convex corners of the hard

mask, which are open to ions approaching from wider angles

than those for a feature side. It is difficult to remove an

undercut unless a perfectly 90 deg. hard mask corner is established. However, if the top of the wafer is removed by

polishing to eliminate bowing, then the undercut will be

removed simultaneously.

Crystallographic plane features: At certain temperatures below !90 C, the SF6 gas condensation

increases on the wafer surface. This surge results

in etch rate variation in the different crystallographic orientations

of Si. Crystallographic planes with higher atomic densities

etch more slowly and affect the profile at the hole

bottom. To eliminate this undesired feature, the temperature

must be precisely controlled at ~90 C.

Variations in wafer thickness: To ensure that we etched through the Si in all the holes

across the wafer, it was important that the wafer had a uniform

thickness. Changes in the wafer thickness caused

notching to appear in some hole bottoms. This was caused

by ion deflection by the oxide mask, even though some of

the holes had not etched completely through to the oxide on

the back side. A lower total thickness variation of

<0.0005 mm across the wafer was required to ensure that all

wafer parts etched through completely and simultaneously.

Variations in the DRIE plasma: The DRIE plasma was seen to vary in a concentric ring

pattern across the wafer, and it etched more quickly near the

center. According to Hoekstra et al., the clamping ring

induces a deviation in the electrical field lines in the presheath

and thus produces a deviation in the ion trajectory.

This leads to higher ion concentration in the wafer center.

The DRIE specifications from the manufacturer indicate a

variation of 65% in plasma, leading to the same amount of

variation in the etch depth across the wafer. This specification

was found to be accurate. Considering the variation in

the etch depth, it was necessary to ensure that the oxide on

the back did not break until all features were resolved. This

was accomplished by visual inspection near the end of the

etching routine.

Contamination issues: The DRIE process chamber was contaminated by the

metal masks or by the Bosch process. With the Bosch process,

an unidentified tan powder was found in the chamber,

and this powder was difficult to remove with isopropanol

and cleanroom wipes. Because of this contamination, other

DRIE mask materials for Si were avoided. Even with an oxide

mask and when more than six or seven wafers were

etched without cleaning the chamber, some scratches were

still observed on the wafer table. This caused an increase

in the He flow, which altered the wafer temperature and

produced a hole profile change. This issue was solved by

polishing the table using a Scotch BriteTM 3M No. 96

scouring pad, which produced a smoother aluminum table

for wafer placement.

Trench width calibration: The anisotropic etching rate was highly dependent on the

aspect ratios of the etched features. A lag was found when

etching narrower features. In the initial etches, the mask

design had a trench width that was equal to the diameter of

the holes (0.1 mm). The trenches had a higher etch rate

because they contained more exposed Si, even though they

were the same width as the holes shown in Fig. 17. The trenches thus etched through the wafer before the holes,

causing the samples to separate prematurely inside the

chamber.

In the early stages of the research, the trench features

were eliminated to tune the variables for hole etching only.

When the trench features were added back into the mask, the

width also had to be adjusted. The trench width was calibrated

by using a set of ten lines on a temporary mask. The

line widths ranged from 0.1 to 0.01 mm, with intervals of

0.01 mm. This mask was patterned alongside the holes and

was then etched for 90 min. The trenches were imaged in the

SEM and were compared with the hole etch rate. The etch

rate of the 0.035 mm line width was closest to that of the

holes. Another temporary mask was prepared with 0.035mm

trenches and 0.1mm holes and was patterned and etched.

The 0.035 mm trenches broke through before the holes were

completely etched. The alignment holes (shown and marked

in Fig. 3) toward the wafer’s outer edge had a lower etch

rate. This was because of the nonuniform plasma mentioned

earlier. The alignment holes toward the outer edge required

wider trenches. Further research is underway to determine

appropriate trench widths so that all features can be resolved

without breaking the oxide. Possible solutions might include

the use of a bare Si wafer on the back of the etch wafer,

which would allow etching to continue until all features are

etched.

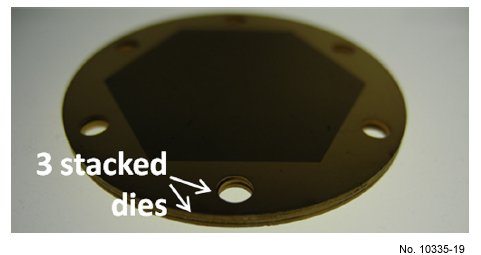

BONDED STACKS OF WAFERS: We used plasma-assisted gold (Au) thermocompression

bonding to stack the etched dies. Au thin films were sputtered

on the etched dies. The Au coated dies were then precleaned

and surface activated in an O2 plasma environment

for 60 s. The dies were pressed manually at room temperature

and were then pressed using a manual hydraulic press.

The stack was then heated to 200 C for 20 min and subsequently

ramped down to room temperature. This experiment

yielded a stack of three etched dies, as shown in Fig. 18.

Hole alignment during the bonding process is still to be

resolved. Future work will involve the use of sapphire rods

inserted completely through the alignment holes (of the

order of 0.1 mm in diameter) of all the bonded dies. This is

important because any deviation from the alignment center

may obstruct the charged particle paths during trapping.

Procedure (Condition): No data

Note: Positrons are charged antiparticles that annihilate upon contact with electrons or any form of

matter. Two of the authors (Lynn and Weber) have proposed a new approach to store large

numbers of charged particles such as positrons. The proposed structure consists of thousands of

0.1-mm-diameter holes etched through silicon wafers, which are then stacked axially to form

cylindrical microtubes to store a large number of positrons. The authors used deep reactive ion

etching on the wafers to create the through-holes with smooth and straight sidewalls. To produce

the best possible etching results, they iteratively modified the etching parameters, including the

chamber pressure, temperature, radio frequency power, inductively coupled plasma power, SF6/O2

gas flow, and O2 gas content. These iterations addressed the fabrication issues that were

encountered, such as bowing, notching, undercutting, nonuniform etch rates across the wafer, and

preferential etching along certain crystal planes. The trench widths were calibrated to match the

etch rates between all the wafer features. The final results enabled the etching of through-wafer

vias with straight sidewalls (89.9–90.1 deg.), smooth surfaces, and high aspect ratios (~5:1) with

minimal defects. This paper describes the etching process used to produce these vias.

Reference: Ankita Verma, Joshah Jennings, Ryan D. Johnson, Marc H. Weber, and Kelvin G. Lynn, Fabrication of 3D charged particle trap using through-silicon vias etched

by deep reactive ion etching, J. Vac. Sci. Technol. B 31(3), May/Jun 2013, pp. 032001-1 - 032001-9.

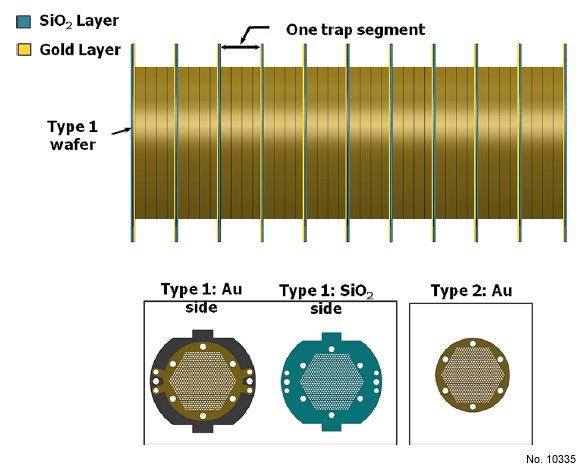

Figure 1: (Color online) Axially stacked wafers contain holes, hence form one

tube with each of the holes.

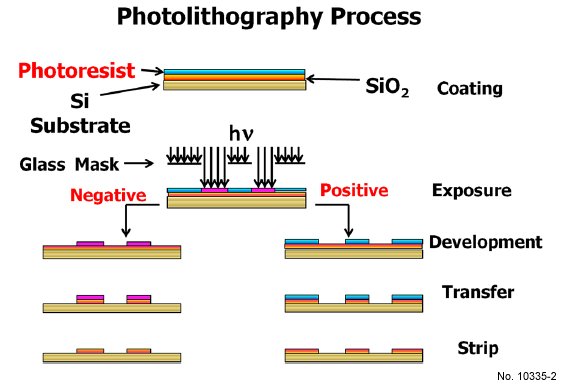

Figure 2: (Color online) Technique of photolithography.

Figure 3: (Color online) Mask used during photolithography.

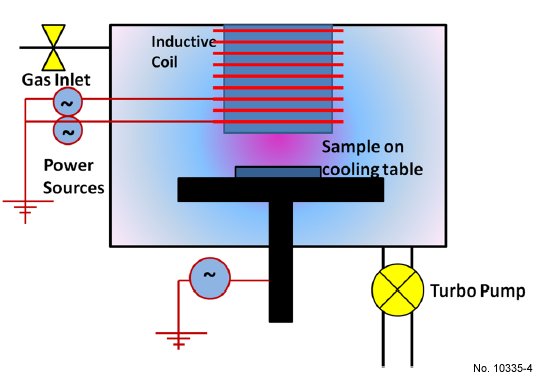

Figure 4: (Color online) Schematic diagram of DRIE with inductive coil which

is not present in RIE.

Figure 5: Hole characteristics measured using SEM.

Figure 6: Slanting edges of etched oxide.

Figure 7: Reactive ion etching result after 1 h of RIE with process pressure of

150 mT, RF power at 150 W, CF4 flow of 30 sccm, and O2 flow of 2 sccm.

Oxide angle after RIE was closer to 90 deg. as compared with earlier attempts

of wet etching.

Figure 8: Irregular wet etching of Cr mask.

Figure 9: Example of an unsuccessful Cr lift off.

Figure 10: (Color online) Examples of ripping effect: (a) Cr thin film sputtered

on SU8 that is patterned on Si, (b) ripped Cr on Si after lift-off, (c) top view

of wafer after lift off.

Figure 11: Image bilayer.

Figure 12: Example of scalloping in Bosch technique. (Dust particles appearing

in the image should be neglected.)

Figure 13: Base etch results in which temperature was ~95 C, pressure was

12 mT, total gas flow (SF6 ž O2) was 76 sccm, O2 percentage in gas was

7.9%, RF power was 3W, and ICP power was 700 W.

Table 1: Results with higher pressure and higher temperature than the base variables after calibration etches.

Figure 14: Result of calibration etches: (a) Higher pressure, (b) higher temperature

than base recipe.

Figure 15: Result of final etch recipe in which temperature was ~90 C, pressure

was 14 mT, total gas flow (SF6 ž O2) was 76, O2 percentage in gas was

7.9%, RF power was 3W, and ICP power was 700 W.

Figure 16: Example of notching and bowing occuring in an etched sample.

Figure 17: (a) Holes etched 306 µm in 120 min. (b) Trenches etched 358 µm in

120 min.

Figure 18: (Color online) Stack of three bonded dies.