Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

AlN, AlxGa1-xN, and GaN - Wet Etching

Material Name: AlN, AlxGa1-xN, and GaN

Recipe No.: 10344

Primary Chemical Element in Material: Al, Ga

Sample Type: Layer

Uses: Etching

Etchant Name: None

Etching Method: Wet etching

Etchant (Electrolyte) Composition: AlN and GaN bulk substrates were obtained from

HexaTech, Inc. and Kyma, Inc., respectively. GaN bulk crystals

were prepared by hydride vapor phase epitaxy (HVPE)

on sapphire substrates followed by substrate removal. AlN

single crystal wafers were obtained from free standing AlN

single crystalline boules grown by physical vapor transport

(PVT). Detailed information on the substrate properties

and wafer preparation can be found elsewhere. Average

dislocation densities of the AlN and GaN wafers were estimated

to be less than 10 exp(3) cm(2) and 10 exp(6) cm(2), respectively,

based on X-ray topography.

Selective etching of the III-polar and N-polar surface

was obtained using KOH aqueous solution. Etching temperature

was maintained at 70 C, and the concentration of KOH

was approximately 0.18 mol/L. AlGaN bulk crystals are currently

not available. Consequently, investigation of the polarity

etching selectivity of AlN and AlxGa(1-x)N (0 <= x <= 1)

was performed using epitaxial films with thickness around

800 nm grown by metalorganic chemical vapor deposition

(MOCVD) on 2-in. sapphire substrates. Using X-ray diffraction

(XRD), the dislocation density of these films was estimated

to be around 3 x 10 exp(10) cm(2). The investigated films

were fabricated as lateral-polarity-structures (LPS) with

alternating 10 lm wide III-polar and N-polar stripes. An

inertness of III-polar material was established in agreement

with the previous work on GaN and AlN. Consequently, LPS

are ideal structures for KOH etching experiments, since the

change of the height difference between the III-polar and

N-polar stripe is a simple but reliable measure of the etching rate.

The surface morphology of the etched AlN and GaN

bulk crystals was characterized by an Olympus BH-2 differential

interference contrast (DIC) optical microscope.

Scanning electron microscope (SEM) images were recorded

using a JEOL 6400F field emission SEM operating at 5 kV.

TEM cross-section samples were prepared by mechanical

wedge polishing followed by Arþ ion milling (Fischione

Model 1010). TEM imaging was performed with a JEOL

2000FX operated at 200 kV.

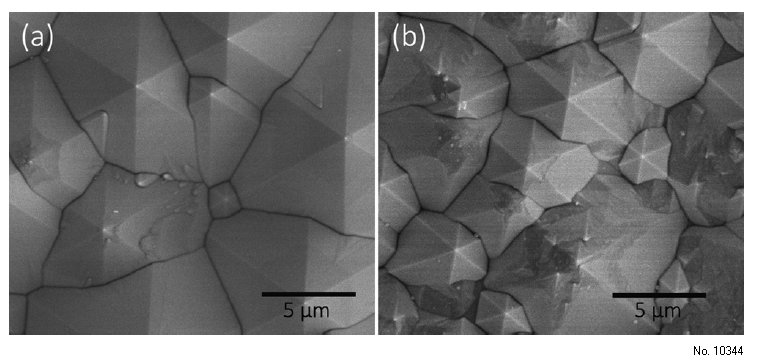

Initially, the surface morphology and etch rates of bulk

AlN and GaN crystals were established to allow for comparison

to the AlGaN layers. N-polar surfaces of AlN and GaN

etched under 0.18 mol/L KOH at 70 .C for 60 min are shown

in Figures 1(a) and 1(b), respectively. Both surfaces were

covered with oriented hexagonal etching hillocks with sizes

ranging from 1 µm to 10 µm. In contrast to the N-polar surface,

III-polar GaN and AlN surfaces were nearly inert to KOH wet etching. Ga-polar and Al-polar surfaces remained

atomically smooth after wet etching under the above condition

and no etching pits or hillocks were observed. The etch

rate of both polarities was determined and it was found that

the N-polar surface had an etch rate around 500 nm/min for

AlN and 40 nm/min for GaN, while the etch rates for IIIpolar

AlN and GaN are extremely low. These values yielded

an N-polar AlN to N-polar GaN selectivity higher than 12

and demonstrated the potential of KOH etching for substrate

thinning application or substrate removal from DUV LEDs

grown on AlN single crystalline substrates.

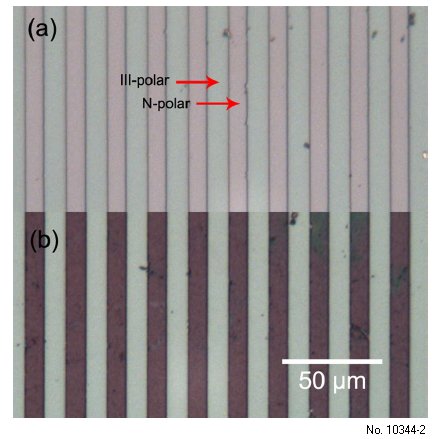

To further investigate the etching selectivity between

AlN and AlGaN, similar wet etching was performed on

AlGaN LPS grown on sapphire substrates. An optical microscope

image of an as-grown Al0.6Ga0.4N LPS (a) and of the

structure after 5 min of KOH etching (b) is shown in Figure

2. The 10 lm wide stripes with alternating III-polar and

N-polar orientation can clearly be distinguished. After the

KOH etching procedure, the III-polar material remained

unchanged. In contrast, the N-polar stripes were significantly

darker, which indicated a significant change of the surface

and thickness of the material.

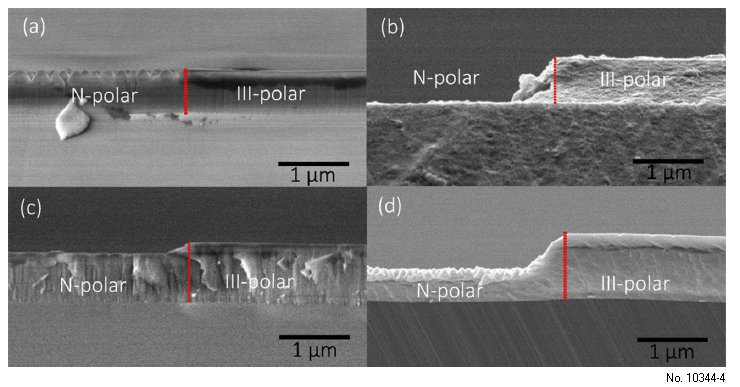

In order to determine the thickness and etch rate, crosssectional

SEM images of AlxGa(1-x)N LPS before and after

etching were recorded. It was found that the etch rate of the

III-polar AlGaN was below 2 nm/min while the etch rate of

the N-polar surface was significantly higher. This was consistent

with the earlier findings on GaN and AlN. Figure 3

shows SEM images of LPS with two different Al compositions. The red dashed line represents the inversion

domain boundaries. In the as-grown AlN LPS, the N-polar

and III-polar stripes equal in thickness even though the surface

morphology differed (Figure 3(a)). After the sample

was etched in 0.09 mol/L KOH aqueous solution for 6 min,

the N-polar region (~800 nm thick) was completely

removed, exposing the sapphire substrate, see Figure 3(b).

For the sample with 60% Al content, as revealed by Figures

3(c) and 3(d), the height difference between the N-polar and

III-polar Al0.6Ga0.4N changed from 140 nm to 450 nm, which

indicated a decrease in the etch rate with respect to AlN.

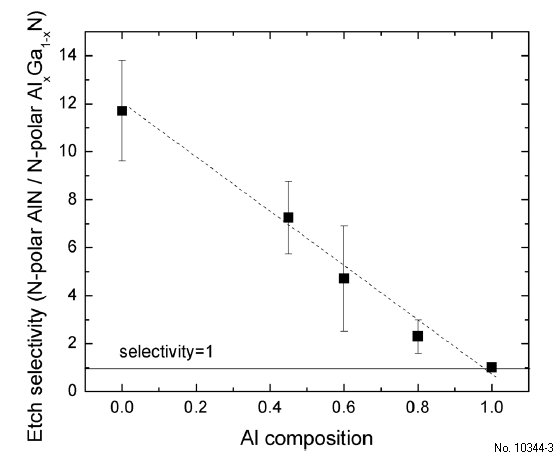

The selectivity between the N-polar AlN over N-polar

AlxGa(1-x)N as a function of Al composition is shown in

Figure 4. An etching selectivity to AlN greater than 1 was

observed over the whole compositional range of AlGaN. It

was further observed that the selectivity increased as Al

composition decreased. The maximum etching selectivity of

around 12 was achieved between AlN and GaN LPS. The

etch selectivity obtained under similar conditions for low

dislocation density bulk AlN and GaN crystals was approximately

13. This conforms to the data obtained for the LPS,

although the dislocation density in these structures was several

orders of magnitudes higher than that of the bulk AlN

and GaN materials. This indicated that under these mild

etching conditions, the dislocations did not play a role in the

etching behavior, and this etching scheme was demonstrated to be a very universal substrate removal method for materials

grown by different methods with different crystalline quality.

The formation and development of etching hillocks could

only be attributed to different bonding conditions of crystallographic

planes, which was an intrinsic property of IIInitride

crystal structure.

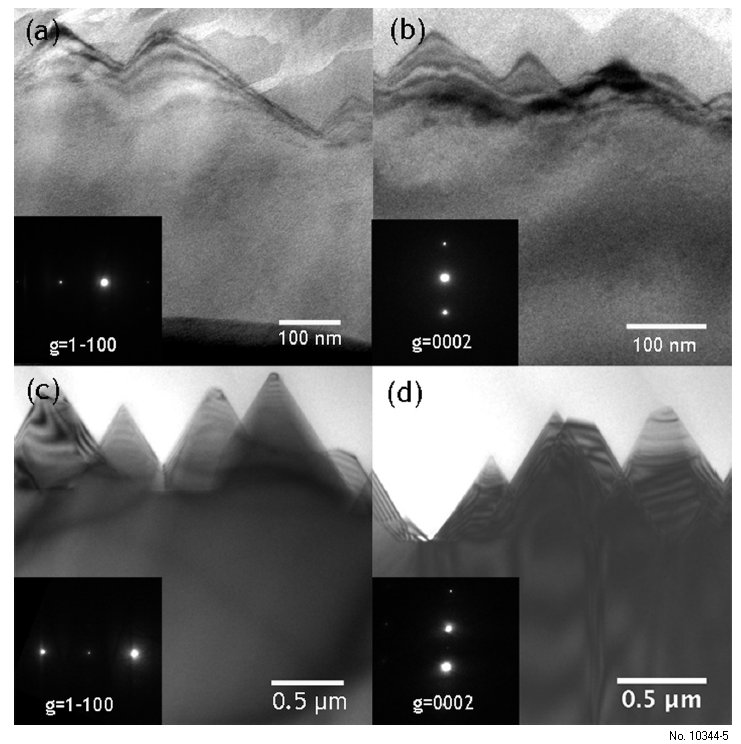

In order to demonstrate the relationship between etching

hillocks and underlying threading dislocations, thus further

generalize the etching behaviour for various materials’ system,

cross-sectional TEM was performed on N-polar AlN

and GaN after KOH etching at 70 C for 30 min, respectively.

As shown in Figure 5, no dislocations were observed

beneath the hillocks for either of the samples (GaN and AlN)

and either of the diffraction conditions (screw and edge dislocation).

Thus, the etch hillocks could not be associated

with dislocations.

Procedure (Condition): No data

Note: A controllable and smooth potassium hydroxide-based wet etching technique was developed for

the AlGaN system. High selectivity between AlN and AlxGa(1-x)N (up to 12x) was found to be

critical in achieving effective substrate thinning or removal for AlGaN-based deep ultraviolet light

emitting diodes, thus increasing light extraction efficiency. The mechanism of high selectivity of

AlGaN as a function of Al composition can be explained as related to the formation and dissolution

of oxide/hydroxide on top of N-polar surface. Cross-sectional transmission electron microscopic

analysis served as ultimate proof that these hillocks were not related to underlying threading

dislocations.

Reference: W. Guo, R. Kirste, I. Bryan, Z. Bryan, L. Hussey, P. Reddy, J. Tweedie, R. Collazo, and Z. Sitar, KOH based selective wet chemical etching of AlN, AlxGa1-xN, and GaN crystals: A way towards substrate removal in deep ultraviolet-light emitting diode, Applied Physics Letters 106, 082110 (2015); doi: 10.1063/1.4913705.

Figure 1: 1. SEM micrographs of N-polar AlN (a) and GaN (b) etched in 0.18

mol/L KOH solutions at 70 C for 60 min.

Figure 2: Optical microscope image of an Al0.6Ga0.4N LPS with 10 µm stripes

before (a) and after KOH etching (b).

Figure 4: Etch selectivity (AlN/AlxGa1.xN) as a function of Al composition

under KOH (0.09 mol/L, 50 C) etching condition.

Figure 3: Cross-sectional SEM images

of AlN LPS before (a) and after (b)

etching under 0.09 mol/L KOH solution

at 50 C for 6 min; Al0.6Ga0.4N

LPS before (c) and after (d) etching

under 0.09 mol/L KOH solution at

50 C for 6 min.

Figure 5: Cross-sectional TEM images

of AlN ((a) and (b)) and GaN ((c) and

(d)) for two diffraction conditions after

KOH etching for 30 min. No correlation

between the hillocks and dislocations

is observed.