Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

GaAs - Wet Etching

Material Name: GaAs

Recipe No.: 10345

Primary Chemical Element in Material: Ga

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Wet etching

Etchant (Electrolyte) Composition: Several wet chemical digital etching techniques were

attempted to determine one that provided consistent and

reproducible results. An important step in the etching

process is to completely separate the chemicals used for

each part of the digital etch step (oxidation step and oxide

etching step). That is, it is necessary to completely rinse the

H2O2 before applying the acid, and vice versa. Residue of

either H2O or acid on the GaAs wafer will mix with the

next application of acid or H2O2 and provide a normal acid:

H2O2 etchant that destroys the controlled, self-limiting digital

etching process. Because H2O2 and many acids contain

water, the use of deionized water (DI H2O) was selected to

provide the necessary rinsing between each step. To prevent

dilution of the chemical agents, an N2 blow dry is used

to remove any water remaining after rinsing.

A new method was developed to provide separately

fresh oxidizing and etching solutions to the sample during

each etch step to minimize chemical cross contamination.

Since contamination due to incomplete rinsing must be

eliminated to maintain the digital etching chemistry, a

photoresist spinner was modified to perform the digital

etching procedure. The modification of the photoresist

spinner consisted of replacing exposed metal parts (wafer

chuck, vacuum shaft, and spinner baseplate) with oxidizer

and acid resistant high density polypropylene machined

to original specifications. With the spinner, fresh oxidizing

and etching solutions can be sprayed from above onto the

sample during each etch step. The spinning motion removes

the applied solution quickly, and allows the application

of a continuously fresh stream of solution. DI H2O

rinsing of the wafer can also take place while spinning,

providing a continuously fresh water stream to remove the

oxidizing and etching solutions. In this manner, fresh solutions

of H2O2, acid, and DI H2O are applied to the sample

during the digital etch, thereby eliminating cross contamination

between H202 and the acid.

Process development has demonstrated that successful

digital etching requires the use of uncontaminated oxidizing

and etching solutions with complete rinsing between

the oxidizing and acid etching steps. Spin rinsing with

fresh DI H20 for 15 s at 1000 rpm was found to be sufficient

to remove both the oxidizing and etching solutions

from the wafer before applying the next solution in the digital etch process. However, it was determined that spinning

the wafer during applications of the oxidizing and

etching solutions was not necessary, as soaking the wafer

during these steps was determined to be sufficient. The

measured digital etch rates of this soak and spin rinsing

method are equivalent to those obtained using the continuous

spin technique. Soaking is desirable because it provides

a large reservoir of solution to perform the necessary

oxidation and etching without depleting the solution.

Because these experiments were performed manually, the

static chemical soak and spin rinsing technique was used

to maintain repeatability and reproducibility, as it was

difficult to insure complete coverage with manual spraying,

whereas a static flood was easy to accomplish and

maintain during the given soak times. The digital etching

experiments conducted in this work used a combined

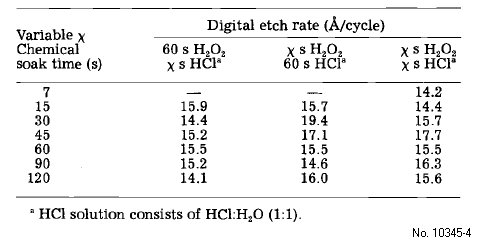

chemical soak and spin rinsing procedure as outlined in Table 1.

Procedure (Condition): No data

Note: A new room temperature wet chemical digital etching technique for GaAs is presented which uses hydrogen peroxide

and an acid in a two-step etching process to remove GaAs in approximately 15 A increments, In the first step, GaAs

is oxidized by 30% hydrogen peroxide to form an oxide layer that is diffusion limited to a thickness of 14 to 17 A for time

periods from 15 to 120 s. The second step removes this oxide layer with an acid that does not attack unoxidized GaAs.

These steps are repeated in succession until the desired etch depth is obtained. Experimental results are presented for this

digital etching technique demonstrating the etch rate and process invariability with respect to hydrogen peroxide and

acid exposure times.

Reference: Gregory C. DeSalvo, et al., Wet Chemical Digital Etching of GaAs at Room

Temperature, Journal of The Electrochemical Society, 143 (11), 1996, pp. 3652-3656.

Table 1: Experimental procedure used to perform a single wet chemical digital etching cyde.

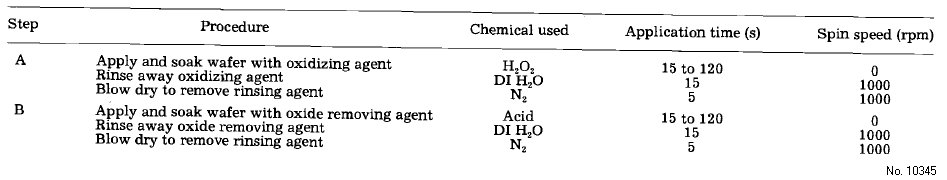

Table 2: Digital etch rate dependence on acid or base using a 10 cycle digital etch step repetition with 1 min acid soaks and

1 min H202 soaks.

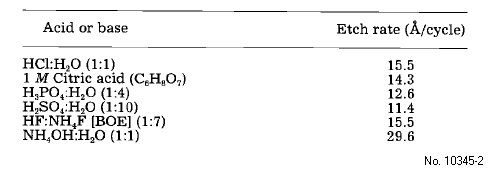

Table 3: Digital etch rate dependence on the number of digital etch cycles performed using 1 min HCI:H20 (l:1) soaks and 1 in H202 soaks.

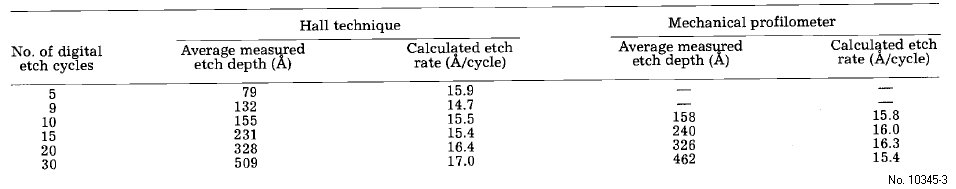

Table 4: Digital etch rate dependence on digital etch soak time

using a ten cycle digital etch repetition.