Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

InAs/GaSb - Wet Etching

Material Name: InAs/GaSb

Recipe No.: 10347

Primary Chemical Element in Material: In, Ga

Sample Type: Layer

Uses: Etching

Etchant Name: None

Etching Method: Wet etching

Etchant (Electrolyte) Composition: This study focuses on the sidewall roughness

and crystallographic orientation selectivity of

mid-wave and long-wave InAs/GaSb SL photodiodes

while wet etching with etchants based on

H3PO4/H2O2/H2O/C6H8O7. The etching of InAs

and GaSb bulk materials is also examined in this work.

After photolithography of the MWIR and

LWIR materials, a chemical solution based on

H3PO4/H2O2/H2O/C6H8O7 was used for wet etching,

where the phosphoric acid (85%), hydrogen peroxide

(30%) and citric acid (100.0%) solutions were

mixed in different proportions. Prior to wet etching,

the samples were cleaned by acetone, absolute ethyl

alcohol and deionized water to remove organic impurities,

with a subsequent cleaning in hydrochloric acid

(3.5%) to remove the surface oxides. The samples were

then rinsed in deionized water and dried with N2 gas.

The etching rates varied for the different solutions,

and the sidewall angles and roughness also varied.

To understand the mechanisms of InAs/GaSb SLs

wet mesa etching, the InAs and GaSb materials were

etched separately by using H3PO4/H2O2/H2O and

H3PO4/H2O2/H2O/C6H8O7 solutions in varying proportions

for InAs and GaSb substrates, respectively.

To analyze the process of chemically etching InAs/GaSb SL photodiodes under various conditions,

we vary the proportions of the four wet chemical

etchant components including H3PO4, H2O2, C6H8O7

and H2O, and observe the roughness of the mesa sidewalls

and the etch depth (i.e., etching rates) via scanning

electron microscopy (SEM). The sidewall roughness

can be observed via the SEM images, while they

cannot be used to measure the roughness. However,

the sidewall roughness can be inferred from the surface

roughness after etching, and the results of data

from atomic force microscopy (AFM) and the SEM

images also verify this relationship.

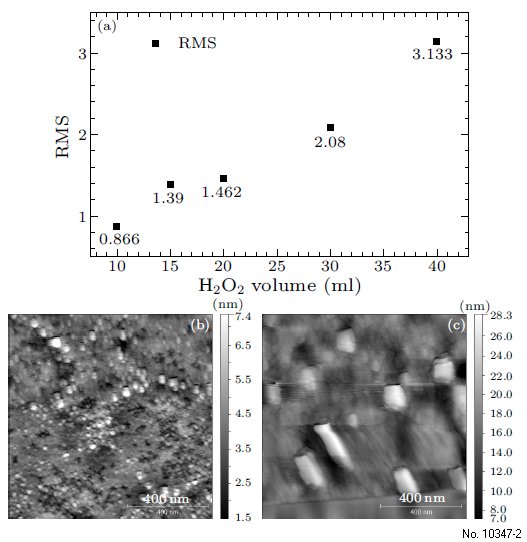

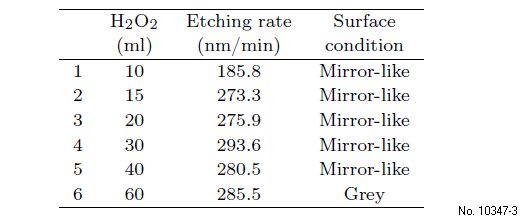

Firstly, we focus on the MWIR and study the role

of hydrogen peroxide in the etchant, where the etching

rates and the surface roughness are given in Table

2 and in Fig. 1(a). It can be seen that, when the hydrogen

peroxide reaches a threshold value, it cannot

influence the etching rate. Instead, after the hydrogen

peroxide reaches its threshold value, the sidewall

roughness increases with the proportions of hydrogen

peroxide. Figure 1(b) shows an AFM image of the

surface exhibiting the greatest and least amount of

roughness.

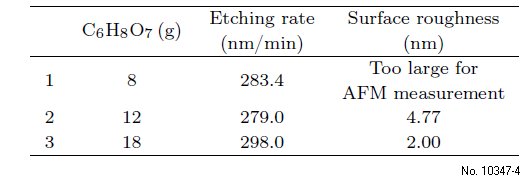

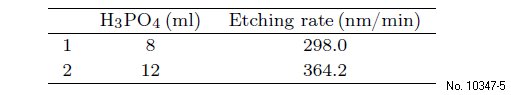

Next, the roles of citric acid and phosphoric acid in

etching the MWIR are studied, and the etching rates

and sidewall images are given in Tables 3 and 4. It

can be seen that the final etching rate is more correlated

with the phosphoric acid and that increased

smoothing of the sidewalls and surface occurs with

increasing the proportions of citric acid. The corresponding

experiments examining the variation of the etchant components on the LWIR InAs/GaSb SLs exhibit

the same variational tendency in the etching

rates and roughness values as those seen in the MWIR

InAs/GaSb SLs.

The presence of complex MPO4 (i.e., InPO4,

GaPO4, AsPO4 and SbPO4) and oxides on the surface,

however, can strongly deteriorate the mesa surface

sidewalls, thus citric acid is used to increase

the smoothness of the sidewalls. After the experiment,

we obtain an optimized chemical solution

(C6H8O7:H3PO4:H2O2:H2O=0.75 g:1 ml:0.6 ml:2 ml)

for MWIR InAs/GaSb SLs with an etching rate of 200 nm/min, which produces much smoother sidewalls

than the previous etchant (citric acid solution

:H3PO4 :H2O2 :H2O=1ml : 1ml : 2 ml : 20 ml, citric

acid solution=C6H8O7 :H2O=1g : 1 ml).

In addition, the results of the InAs and GaSb materials

show that InAs etchants without citric acid also

produce sidewalls with excellent performances, and

the GaSb etching requires a more highly concentrated

solution than that previously used for InAs/GaSb SLs.

Therefore, if we increase the amount of InAs in the

SLs, we can reduce the amount of citric acid and, likewise,

if the amount of GaSb is increased, an etchant

with a higher concentration is needed.

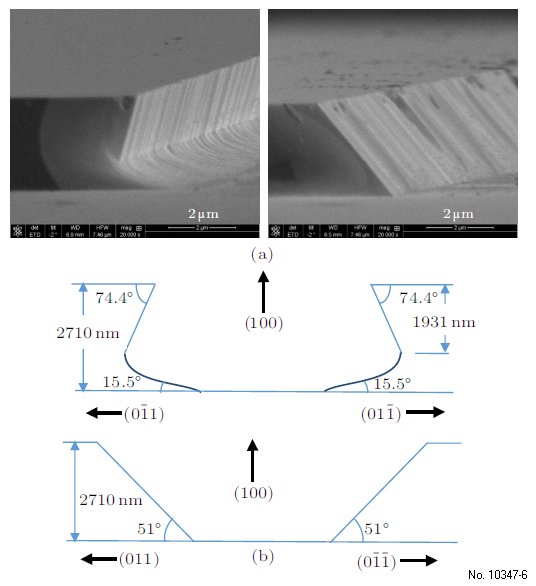

There is an obvious anisotropy seen in the etching

profile of InAs materials, and in an attempt to

reduce this anisotropy we tried different (100) substrates

and etchants based upon H3PO4/H2O2/H2O,

shown in the SEM image in Fig. 3(a). Although the

angles and turning positions vary, the etching profiles

are all in the same situation as that shown in Fig. 3(b).

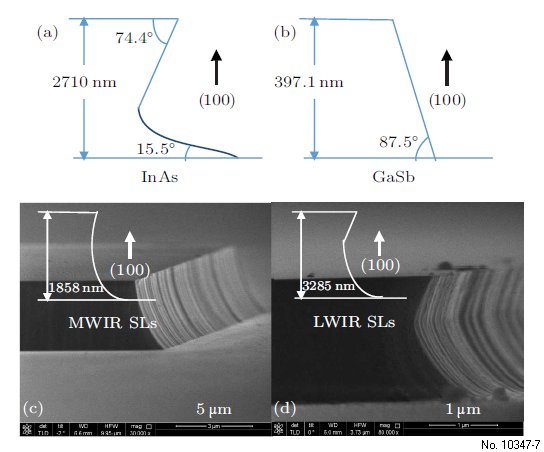

We now compare the four different kinds of materials

including InAs, GaSb, MWIR SLs and LWIR

SLs, whose profiles are shown in Fig. 4, where it can be seen that, even in the same crystallographic orientation,

wet chemical etching of InAs and GaSb has

markedly different profiles. From the SEM profiles of

the MWIR and LWIR SLs, we can see that the profile

of each InAs/GaSb SLs corresponds to that of its

most prevalent component. For example, LWIR SLs

with more InAs have the profile most similar to that

of InAs bulk materials.

Procedure (Condition): No data

Note: The roughness and the crystallographic orientation selectivity of etched antimonide-based infrared materials are

examined and are used to optimize the chemical mesa etching process of the InAs/GaSb superlattice photodiode

with the goal of reducing the dark current. The etchant used is based on phosphoric acid (H3PO4), citric acid

(C6H8O7) and hydrogen peroxide (H2O2). The roughness of the mesa sidewalls and etching rates are compared

and used to find an optimized etchant.

Reference: HAO Hong-Yue, et al., Wet Chemical Etching of Antimonide-Based Infrared Materials, CHIN. PHYS. LETT. Vol. 32, No. 10 (2015) pp. 107302-1 - 107302-4.

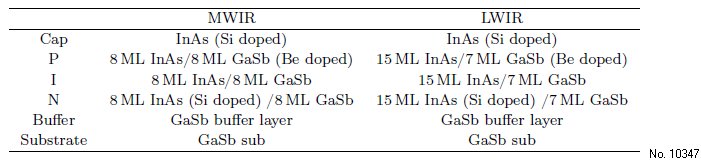

Table 1: The structures of MWIR and LWIR InAs/GaSb photodiodes.

Figure 1: (a) Surface roughness materials in different

etchants. (b) AFM image of the surface.

Table 2: Etching rate with different volumes of hydrogen peroxide.

Table 3: Etching rate and surface roughness with increasing

the citric acid.

Table 4: Etching rate in etchants with different phosphoric

acids.

Figure 3: Nonisotropic of InAs wet etching shown by (a)

SEM images and (b) plots.

Figure 4: Profiles of (a) InAs, (b) GaSb, (c) MWIR SLs and

(d) LWIR SLs in the (011) crystallographic orientation.