Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

PDMS - Dry Etching

Material Name: PDMS

Recipe No.: 10352

Primary Chemical Element in Material: No data

Sample Type: Layer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: The PDMS used throughout the study was Sylgard 184

from Dow Corning Corp, Midland, MI. The elastomer was

mixed in a 10:1 ratio with its curing agent and then placed in

a desiccator for at least 45 min to remove the bubbles created

during mixing. Samples were then made by either spinning

the polymer on precleaned glass slides and curing at 90 °C,

or by pouring it into plastic weighing dishes and curing at low heat.

The wet etch experiments were performed using a solution

of tetrabutylammonium fluoride (C16H36FN) in

n-methyl-2-pyrrolidinone (C5H9NO), 3:1 (v/v) NMP:TBAF,

both supplied by Sigma-Aldrich. The surface of the PDMS

was first coated with copper or aluminum either by sputtering

or electron-beam evaporation. Rectangular windows

were then etched in the metal masking layer using standard

photolithographic processing and wet etching. The PDMS

was then immersed in the solution and gently agitated during

the etch. Agitation was required due to the relatively slow

etch rate, and the need to replace etchant at the surface, as is

commonly done in the laminar flow etch process described

by Takayama et al.3 The substrates were periodically removed

from the etchant, rinsed with isopropanol and water,

dried with nitrogen, and examined under the microscope in

order to monitor the etch progress. Results of this approach

are shown in Fig. 3 and discussed in the following section.

Dry etching experiments were performed in an Oxford

Plasma Technology mP 80 parallel plate reactor equipped for

reactive ion etching. Oxygen (O2) and tetrafluoromethane

(CF4) gases were supplied by Messer, MG Industries, Malvern,

PA. All samples used for etch rate determination were

etched for 60 min while the CF4/O2 ratio, total gas pressure,

and RF power were varied (see Table 1). The surface of each

sample was partially masked with Kapton tape prior to etching

in order to create a distinct step feature that could be

measured using a Dektak 3030 stylus profilometer. The step

height was also measured using a Leitz Ergolux optical microscope

with a calibrated reticle. Each sample was cross

sectioned and laid flat on a microscope slide to obtain a side

view of the etch profile. Several cross sections were taken for

each sample and the average step-height value was used.

Procedure (Condition): No data

Note: A fluorine-based reactive ion etch (RIE) process has been developed to anisotropically dry etch the

silicone elastomer polydimethylsiloxane (PDMS). This technique complements the standard

molding procedure that makes use of forms made of thick SU-8 photoresist to produce features in

the PDMS. Total gas pressure and the ratio of O2 to CF4 were varied to optimize etch rate. The RIE

recipe developed in this study uses a 1:3 mixture of O2 to CF4 gas resulting in a highly directional

and stable etch rate of approximately 20 mm per hour. Selective dry etching can be performed

through a photolithographically patterned metal etch mask providing greater precision and

alignment with preexisting molded features. The dry etch process is presented in this article along

with a brief comparison to recently reported wet etch approaches.

Reference: J. Garra, et al., Dry etching of polydimethylsiloxane for microfluidic systems, J. Vac. Sci. Technol. A 20(3), May.Jun 2002, pp. 975-982.

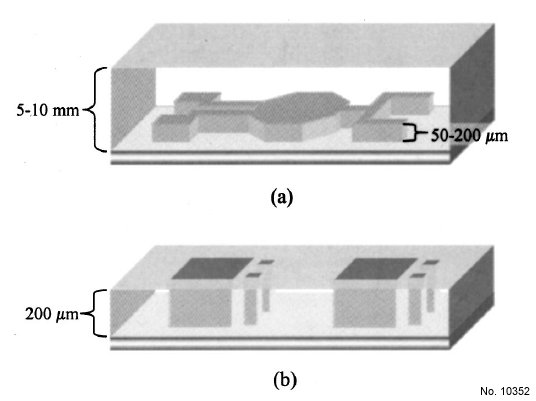

Figure 1: (a) Thick PDMS layer cast in SU-8 mold. The SU-8 features are

patterned in the surface of the PDMS. (b) The PDMS cast in the SU-8 mold

has the same thickness as the SU-8 itself. The mold features extend through

the membrane.

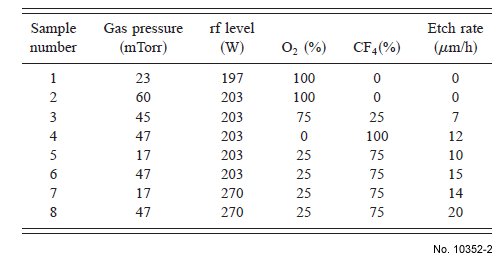

Table 1: Dry etch data for PDMS at varying pressures and gas ratios. All

etches were performed for 60 min.

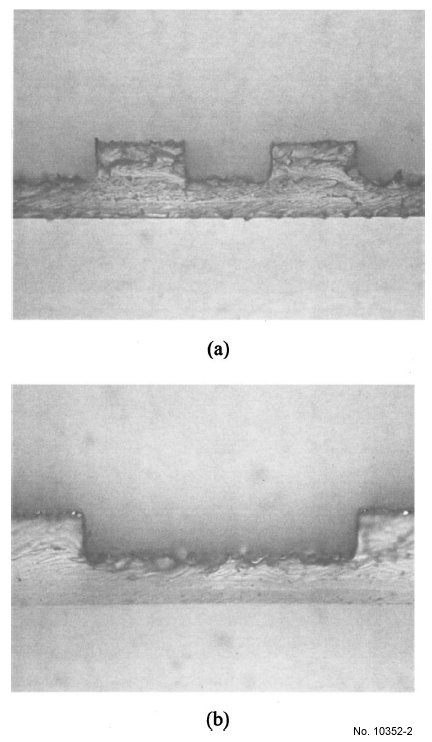

Figure 2: Cross sections of two different structures, (a) and (b), etched in

PDMS as seen under the optical microscope at 203 magnification. The twin

structures in (a) are roughly 140 µm wide and 60 µm high. The rectangular

etch cavity in (b) is 350 mm wide and 60 mm deep. The measurement reticle

is not visible in the pictures.

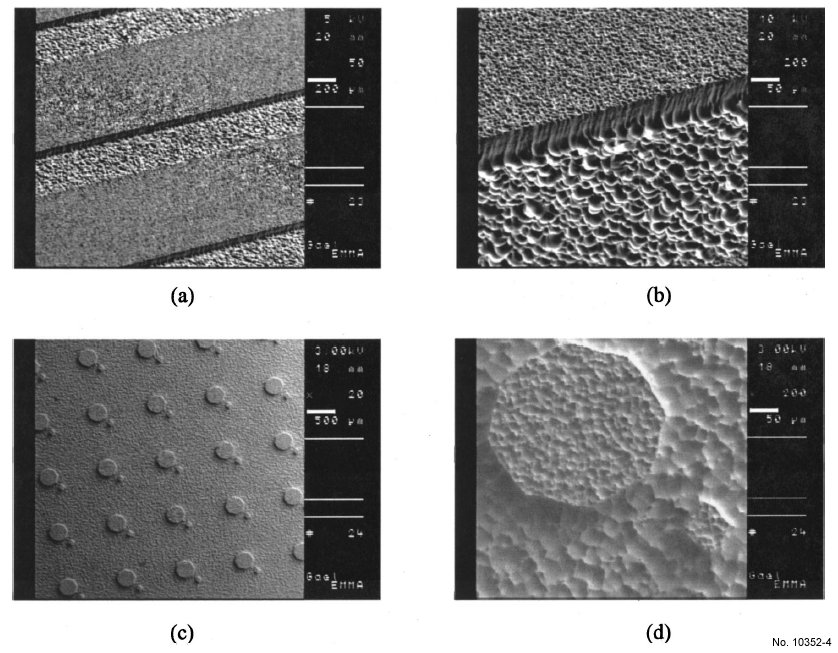

Figure 3: Two different patterns were etched into the PDMS samples through lithographically defined aluminum masking layers to show how dry etching can

be used to bulk micromachine structures in the surface of PDMS. The first structure, shown in (a) and at increased magnification in (b) consists of a series of

parallel channels 350 µm wide and 70 µm deep. The second structure, shown in (c) and again in (d) is an array of octagons (300 µm wide) and rhombuses

(45 µm wide) raised 70 µm from the bottom surface. The micrographs show the roughness characteristic of the etched PDMS surface.