Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Tungesten - Dry Etching

Material Name: Tungesten

Recipe No.: 10353

Primary Chemical Element in Material: Ti

Sample Type: Layer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: Three different etching equipment are used.

1. A Cobrain swafer--Power, at 25 kHz frequency, is applied

at the lower electrode leaving the upper electrode

grounded in the RIE mode, or at the upper electrode leaving

the lower electrode floating in a PE mode.

2. A Tegal HRe-system--Permanent magnets are placed

around the cylindrical wall and above the upper electrode.

The upper electrode is always grounded. It is possible to

apply power at 13.56 MHz at the wall os the reactor (PE

mode) or at the lower electrode (RIE mode).

3. A few experiments were performed using MATRIX 303 equipment--A remote plasma is created in the upper

part of the reactor, while the wafer is placed in the lower

part, on a heated chuck. Both parts of the reactor are divided

by a grid made of aIumina.

Procedure (Condition): No data

Note: No data

Reference: Patrick Verdonck, et al., Analysis of The Etching Mechanisms of Tungsten in

Fluorine Containing Plasmas, J. Electrochem. Soc., Vol. 142, No. 6, June 1995, pp. 1971-1976.

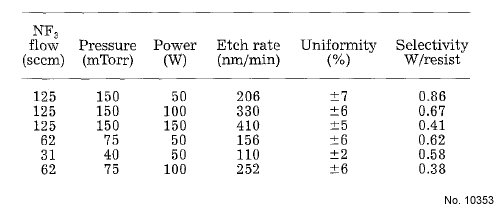

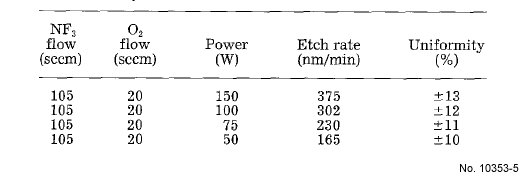

Table 1: Tungsten etch rates, uniformities, and selectivities

toward resist as a function of pressure and power

in the SWAFER reactor in RIE mode.

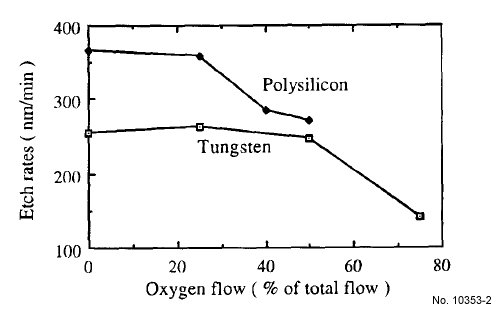

Figure 1: Tungsten and polysilicon etch rates as a function of oxygen

flow, for NF3-O2 plasmas in the RIE mode, at 150 mTorr pressure, and

50 W power in the SWAFER reactor.

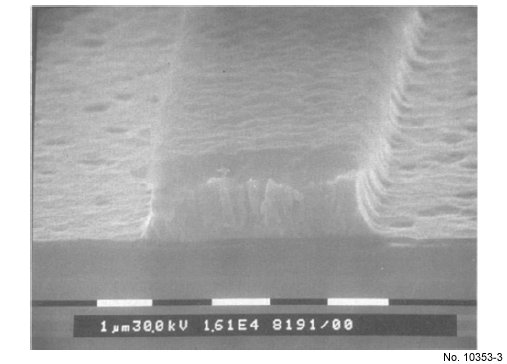

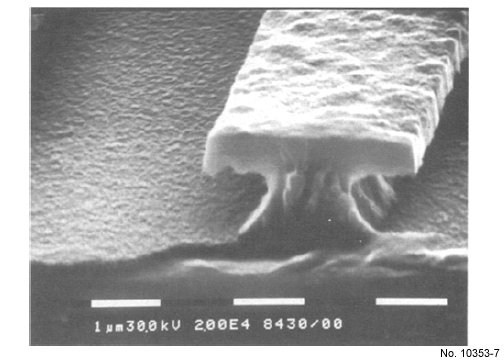

Figure 2: Tungsten profile after RIE etching with a pure NF3 plasma

using a PECVD oxide mask.

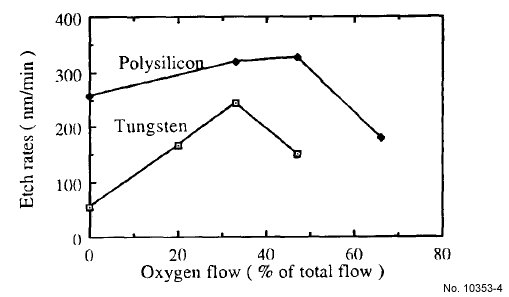

Figure 3: Tungsten and polysilicon etch rates as a function of oxygen

flow, for NF3-02 plasmas in PE mode, at 150 mTorr pressure and

50 W power in the SWAFER reactor.

Table 2: Tungsten etch rates and uniformities as a function

of power in the SWAFER reactor in PE mode.

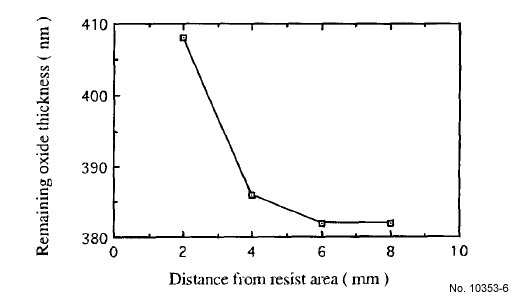

Figure 5: Remaining PECVD oxide thickness as a function of distance

from a large resist area after a PE mode etching with a NF3-O2

plasma in the SWAFER reactor.

Figure 6: Tungsten profile after PE mode etching with a NF3-O2

plasma, using a PECVD oxide mask.

Figure 7: Tungsten and polysilicon etch rates as a function of oxygen

flow and etching mode. Total flow, 96 sccm: pressure, 10 mTorr:

power, 400 W in the TEGAL HRe-reactor.

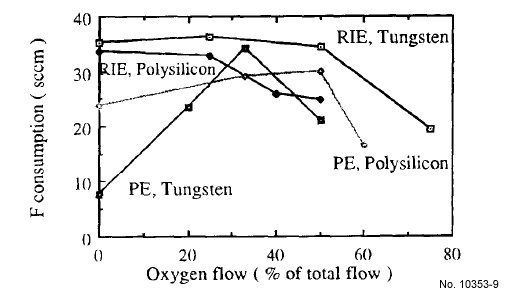

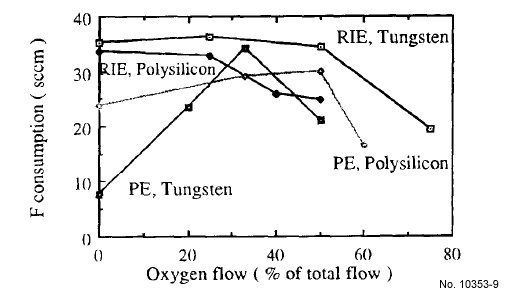

Figure 8: Fluorine consumption for tungsten and polysilicon etch processes

as a function of oxygen flow and etching mode in the SWAFER.

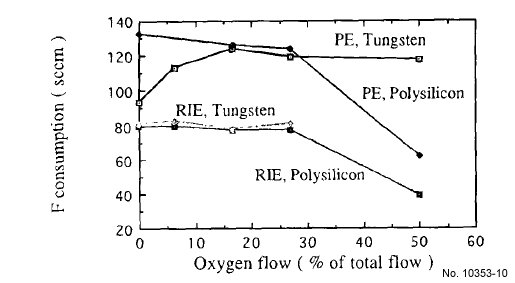

Figure 9: Fluorine consumption for tungsten and polysilicon etch processes

as a function of oxygen flow and etching mode in the Tegal HRe-.