Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Si, Ge, and Ge:P - Dry Etching

Material Name: Si, Ge, and Ge:P

Recipe No.: 10354

Primary Chemical Element in Material: Si, Ge

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

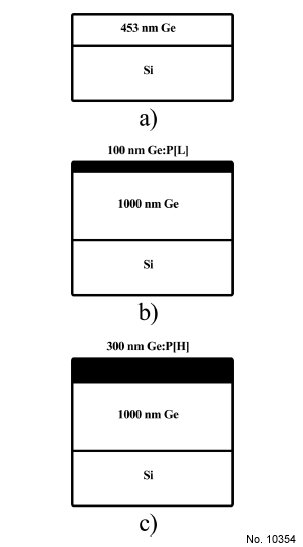

Etchant (Electrolyte) Composition: In this experiment, 100mm diameter, low-doped (1–10 Ohm x cm) Si(001) substrates were used and Ge and Ge:P layers

grown on the Si substrates. Growth was performed by

reduced pressure chemical vapor deposition in an ASM

Epsilon 2000 reactor using germane (GeH4), where the specific

growth properties and material properties of these

layers have been previously reported.1 The doping concentrations

of the final Ge layer were 1 x 10 exp(18) cm(-3) (herein

referred to as “lightly doped,” Ge:P[L]) and a 3 x 10 exp(19) cm(-3)

(referred to as “heavily doped,” Ge:P[H], respectively.

a) Schematic diagrams of the samples are presented in Fig. 1.

The investigation was performed on small (7 x 7 mm2)

pieces of the grown wafer where photolithography was performed

using a 1.8 µm S1813 photoresist, a Karl Suss MJB4

mask aligner, and MF-319 developer to create mesas of photoresist

of width 8 µm, and 8 µm spacing, and 2mm long,

alighted along the <1 1 0> direction. Samples were cleaned

by deionized water and then dried with nitrogen.

The apparatus for dry etching used in this work was the

Corial 200 IL operating at a frequency of 13.6 MHz and using

gas sources of SF6 (99.999%), O2 (99.9995%), and He

(99.999%) as a temperature control gas to a handle wafer,

upon which the sample was placed. All fabrication equipment

used was housed and operated in a class 100 clean room. The

RIE process parameters were: working pressure of 20 mTorr,

RF power 100 W, and total gas flow of 30 sccm. A cooling system was used to keep the handle wafer at a constant temperature

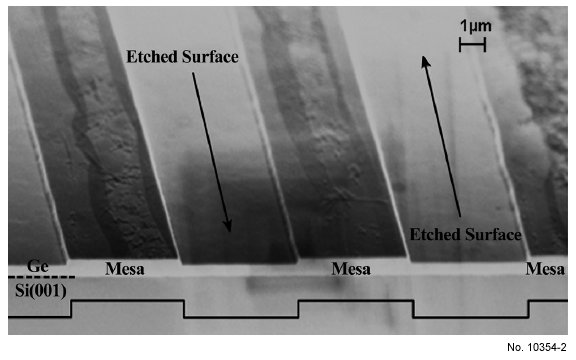

of 20 C throughout the etch process. Surface steps were measured using an Ambios XP-100

step-profilometer. After RIE, the mesa height was measured

postresist removal, an example of which is shown in Fig. 2.

The mesa step without resist measured the vertical amount

of material removed and in conjunction with the etch time

this determining the etch rate. To investigate the results of

anisotropy, samples were then cleaved along h1 1 0i directions

across the mesas so that their cross-sections could be

examined by secondary electron microscopy (SEM) using an

accelerating voltage of 5 kV and a Zeiss Supra InLens backscattered

electron detector.

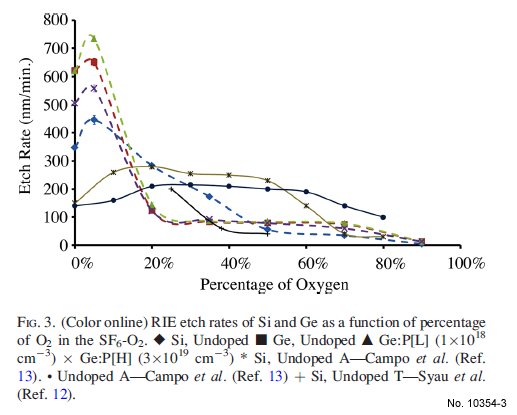

Figure 3 shows the measured etch rates versus O2 dilution

(%O2). A sharp rise in etch rate is observed for all samples

when O2 was introduced into the SF6 up to% O2 of 5%, and

then fell as the O2 dilution was increased beyond this value.

Specifically, the Si etch rate declines linearly as %O2

increases from 5% to 50%, and then has a slow linear reduction

up to 90%. Ge and Ge:P etch rates rapidly decline as %O2 increases to 20%, above which the etch rate levels off

and remains roughly constant up to 70%O2, approaching

zero at 90%. The effect of doping level upon the etch rate is

more significant at lower O2%, where the etch rate of the

lighter doped Ge:P[L] is higher than the intrinsic Ge (i-Ge),

which are both higher than that of heavily doped Ge:P[H].

Where O2>20%, the etch rate of all types of Ge samples

are similar and does not show any differences. Overall, the

O2 content has a larger influence on etch rate compared to

doping level when O2 content is more than 20%, whereas

doping effects are more prevalent with O2 content below 20%.

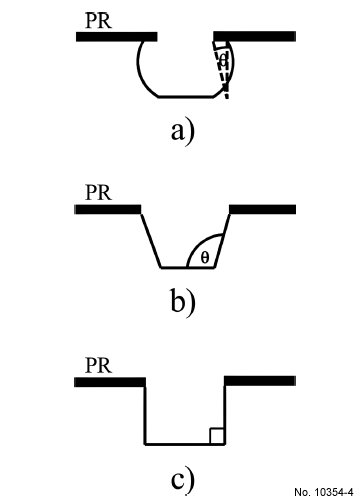

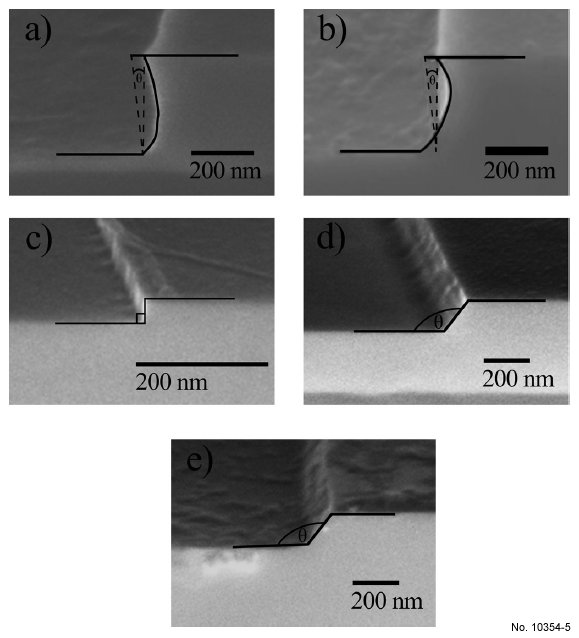

Sidewall profile

Our definition for the etch sidewall profile and the associated

measured angle11 are shown in Fig. 4. The samples are

patterned on the h110i directions and are cleaved using

standard cleaving techniques perpendicular to the mesa

direction. The etched mesas are analyzed by SEM and anisotropic

etching is evident for all samples, where images of the

sidewalls are shown in Fig. 5 and are presented graphically

in Fig. 6. When the Si and Ge sidewall angles are compared,

it is observed that there is no significant difference. The perfect

anisotropic mesa, where theta=90 deg., is achieved with

%O2¼20%. This is the critical concentration beyond which

the angle changes from acute to obtuse; these observations

are consistent with a transition between plasma-to-sputter--

dominated etching, the isotropic profile being caused by

plasma etching and anisotropic profile through physical

etchting.

Reactive ion etching of Si, Ge, and Ge:P has been studied,

using an SF6-O2 gas mixture. The etch rate rises sharply as

small amounts of O2 (up to 5%) are added to a pure SF6 etch

and then decreases when the O2 content is increased further.

The etch rate of Ge and Ge:P is significantly increased over

Si for O2 content in the ranges 0% to 12% and >46%, indicating

that well-controlled selective etching is achievable

simply by varying O2 flow rates. Perfectly perpendicular

sidewalls are also clearly evident close to 20% O2 content,

again allowing excellent etching control. Future work could

usefully investigate the depth of trenches with vertical sidewalls

that could be made using this processing condition. In

summary, adding O2 to SF6 for RIE applications enables significant

advantageous and well controllable variations in the process.

Procedure (Condition): No data

Note: The impact of the O2 content in SF6-O2 gas mixtures on the etch rate and sidewall profile of silicon

(Si), germanium (Ge), and phosphorous doped germanium (Ge:P) in reactive ion etching has been

studied. The characteristics of etch rate and sidewall profile are greatly affected by the O2 content.

Below 50% of O2 content, a large variation in Ge etch rates is found compared to that of Si, but for

O2 content above 50% the etch rates follow relatively the same trend. Lightly doped Ge shows the

highest etch rate at a O2 concentration up to 20%. Sidewall angles range from a minimum of 80. to

a maximum of 166., with O2 concentration of 20% yielding perfect anisotropic mesa etch. Also at

this O2 concentration, reasonable Si/Ge selectivity is possible. These observations indicate that by

adjusting the O2 concentration, precision plasma etching of Si, Ge, and Ge:P is possible.

Reference: Wongwanitwattana, Chalermwat, Shah, Vishal Ajit, Myronov, Maksym, Parker, Evan H.

C., Whall, Terry E. and Leadley, David R.. (2014) Precision plasma etching of Si, Ge,

and Ge:P by SF6 with added O2. Journal of Vacuum Science & Technology A: Vacuum,

Surfaces, and Films, Volume 32 (Number 3). Article number 031302. ISSN 0734-2101.

Figure 1: Schematics of samples: (a) Ge (undoped layer); (b) Ge:P[L] (1 x 10 exp(18) cm(-3); and (c) Ge:P[H] (3 x 10 exp(19) cm(-3).

Figure 2: Ge mesa pattern using RIE, removed photoresist (PR) (still have residual PR).

Figure 3: (Color online) RIE etch rates of Si and Ge as a function of percentage

of O2 in the SF6-O2.

Figure 4: Mesa profiles produced by anisotropic and isotropic etching

(PR= photoresist): (a) Isotropic, (b) partially anisotropic, and (c) perfect

anisotropy.

Figure 5: SEM images of the surface morphology of Ge mesa after dry etching

with SF2-O2 of various O2 percentages: (a) 0%, (b) 5%, (c) 20%, (d) 50%,

and (e) 70%.

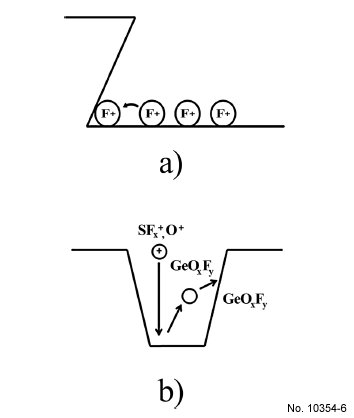

Figure 7: Proposed etch mechanism: (a) the Fþ ions find the site of least potential

energy, the step and therefore etch slightly laterally. (b) GeOxFy is sputtered

from the bottom surface and redeposited onto the sidewall.