Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Ti, SiOx, Si3N4, W, SiC Etch Rates - Wet Etching

Material Name: Ti, SiOx, Si3N4, W, SiC

Recipe No.: 10355

Primary Chemical Element in Material: Ti, Si, W

Sample Type: Wafer, layer

Uses: Etching

Etchant Name: None

Etching Method: Wet etching

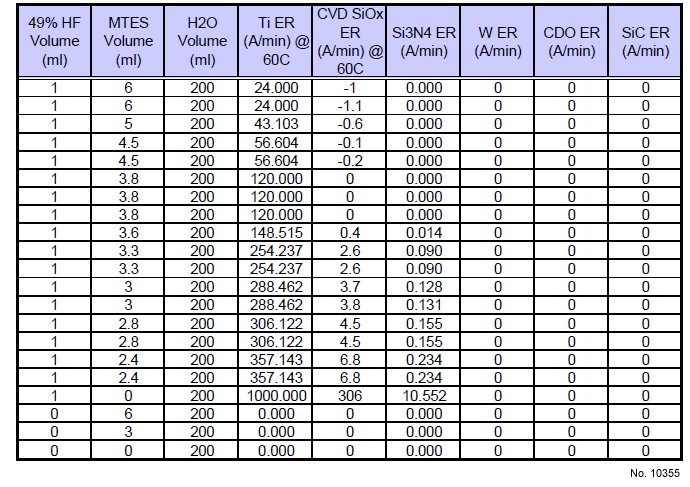

Etchant (Electrolyte) Composition: The etch rate investigation results as a function of volumes are illustrated in

table 1. All experiments were performed at 60 °C. To demonstrate synthesis and

etch rate control and reproducibility, synthesis was carried out in duplicates and etch

rate experiments were performed in triplicates. A temperature of 60 °C was chosen

due to its beneficial enhancement from a cleanability, and etch rate robustness

perspectives. Etch rate is directly proportional to temperature. In addition, 60 °C is a

practical temperature that can be implemented for high volume manufacturing.

Procedure (Condition): No data

Note: No data

Reference: Nabil George Mistkawi, Fundamental Studies in Selective Wet Etching and Corrosion Processes for

High-Performance Semiconductor Devices, PhD Thesis, Portland State University, 2010, pp. 117-118.

Table 1: Etch rates as a function of formulation constituents concentrations.