Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

GaSb - Wet Etching

Material Name: GaSb

Recipe No.: 8508

Primary Chemical Element in Material: Ga

Sample Type: Substrate, bulk

Uses: Etching

Etchant Name: None

Etching Method: Wet etching

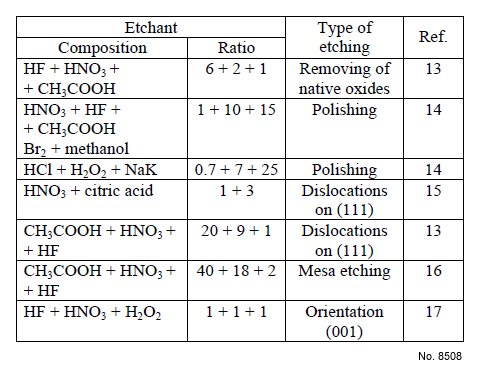

Etchant (Electrolyte) Composition: See the Table 1.

Procedure (Condition): No data

Note: Chemical etchants for GaSb and related compounds are given in Tables 1. Note that InSb, GaSb, and their solid solution require an oxidising agent. Most often HNO3 and H2O2 are used for this purpose. Only AlSb has sufficiently ionic character to not require oxidant and to react with HCl. Optimisation of solution composition is necessary for control of reaction method and products. For example, if the ratio of HNO3 to HCl is very large, insoluble antimony tri- or pentoxide forms while all other ratios yield soluble antimony chlorides. For strong acidic solutions addition of complexing agents such as tartaric or citric acid is necessary for prevent solution from total dissociation. Thus, ratios of HNO3 to organic acids must favour the organic acids. HNO3 is at the same time oxidising and etching agents because it oxidises III-V surfaces and etches III – V oxides (Ga2O3 and In2O3), simultaneously leaving the group V oxides (Sb2O3 and As2O3).

Reference: E. PAPIS-POLAKOWSKA, SURFACE TREATMENTS OF GaSb AND RELATED MATERIALS FOR THE PROCESSING OF MID-INFRARED SEMICONDUCTOR DEVICES, Electron Technology - Internet Journal 37/38 (2005/2006), 4, p. 1-34.

Table 1: Chemical etchants for GaSb.