Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Chalcogenide Glasses (ChG)-Ge23Sb7S70 - Dry Etching

Material Name: Chalcogenide glasses (ChG)-Ge23Sb7S70

Recipe No.: 8515

Primary Chemical Element in Material: Ge

Sample Type: Thin film

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

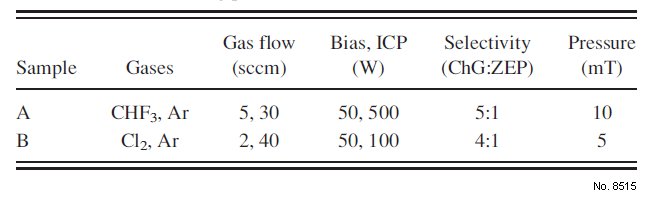

Etchant (Electrolyte) Composition: Plasma etching was performed using a Unaxis

Shuttleline inductively coupled plasma reactive ion etcher

(ICP-RIE). Two different etching recipes based on CHF3 and

Cl2 were investigated in order to determine the best performance

(see Table 1). Both samples A and B were etched by

approximately 290 nm at a temperature of 20 C. Sample A

had a thickness of 600 nm, and sample B was 650 nm thick.

After etching, the samples were coated with a benzocyclobutene

(BCB) polymer cladding to protect the surfaces from

contamination and to reduce scattering from the sidewalls.

The curing of the polymer was performed in a nitrogen oven

at a maximum temperature of 220 C.

Procedure (Condition): Fabrication started with standard solvent cleaning of

100-mm diameter silicon wafers with 2 µm of thermal oxide

grown on the surface. Electron-beam deposition was used to

produce the ChG films on the surface of the silicon dioxide.

This deposition method has been previously reported,11 and

is further investigated here under different deposition conditions.

The deposition was performed at a rate of about 1 nm/a) s, starting with 1.1 cm2 cylindrical rods of bulk glass with the composition Ge23Sb7S70. Bulk Ge23Sb7S70 glass was fabricated

by traditional melt quenching techniques A film approximately 630-nm-thick was deposited on the surface of the wafer.

Note: No data

Reference: Jeff Chiles, et al., Low-loss, submicron chalcogenide integrated photonics with chlorine

plasma etching, APPLIED PHYSICS LETTERS 106, (2015), pp. 111110-1 - 111110-4.

Table 1: Plasma etching parameters.