Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

SiO2, Si3N4, Si - Dry Etching

Material Name: SiO2, Si3N4, Si

Recipe No.: 8518

Primary Chemical Element in Material: Si

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

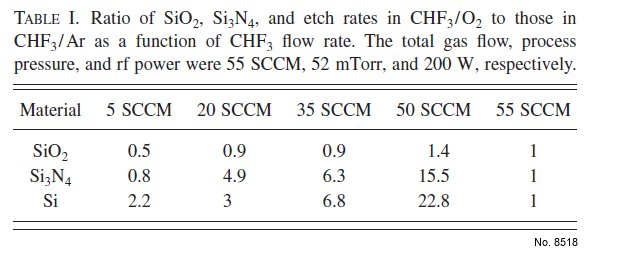

Etchant (Electrolyte) Composition: RIE was performed in an Oxford PlasmaLab80 system

using CHF3 plasma with the addition of either O2 or Ar. The

process pressure was 55 mTorr and the total gas flow rate

was kept constant at 55 SCCM (SCCM denotes cubic centimeter per minute at STP). Samples were placed on the watercooled

(23–24 °C) bottom electrode that was powered by a 13.56 MHz rf generator. The parallel upper and lower electrodes

are 240 mm in diameter. In this study, the exposure time, gas flow ratio, or rf power was varied at any one time.

The rf powers reported are forward powers, as the measured reflected power was insignificant. Experiments were performed

using either O2 or Ar additives to the CHF3 plasma. The etch rate of dielectrics were measured on single-sided

polished Si wafers that were either oxidized thermally (SiO2) or had received Si3N4 by low-pressure chemical vapor deposition.

The thickness of dielectric layer etched for a fixed time was determined using reflectance measurements. The

etch rate of Si was determined by etching mesas on patterned surfaces, followed by measurement with an alpha-step stylus profilometer. See the Table 1.

Procedure (Condition): For studying RIE-induced defects, we used both p- and

n-type Si wafers from boron- and phosphorus-doped float zone (FZ) ingots.

Note: No data

Reference: C. Gatzert, et al., Investigation of reactive ion etching of dielectrics and Si in CHF3/O2

or CHF3 /Ar for photovoltaic applications, J. Vac. Sci. Technol. A 24(5), Sep/Oct 2006, pp. 1857-1865.

Table 1: Ratio of SiO2, Si3N4, and etch rates in CHF3/O2 to those in CHF3 /Ar as a function of CHF3 flow rate.