Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

InP Layer - Dry Etching - Demo Record

Material Name: InP

Recipe No.: 9890

Primary Chemical Element in Material: InP

Sample Type: Layer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: See the Table 1.

Procedure (Condition): No data

Note: In this paper we present a novel single-step RIE process for InP membrane optical waveguide etching. The optimization of the

process is focused on the sidewall verticality and surface roughness of the etched profile. Significant improvement on the etched

profile is achieved for the first time in a single-step RIE process. Loss measurement on fabricated membrane waveguides etched with

the proposed RIE process results in a record low waveguide propagation loss (2.5 dB/cm).

Reference: Yuqing Jiao, et al., Vertical and Smooth Single-Step Reactive Ion Etching Process

for InP Membrane Waveguides, Journal of The Electrochemical Society, 162 (8) E90-E95 (2015).

Other our software: Metal Etchants v.5.0

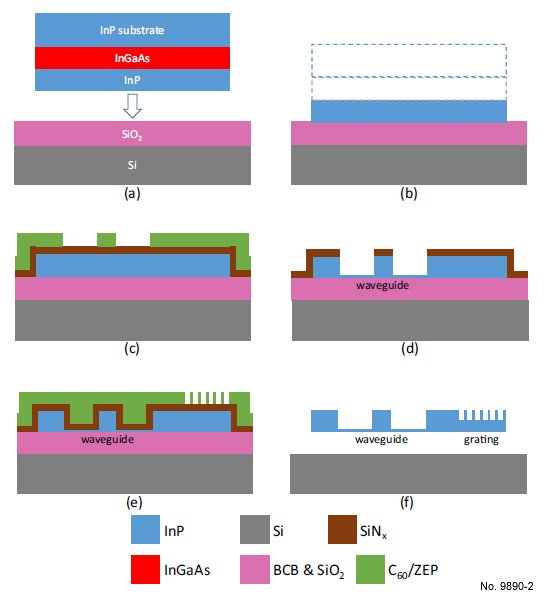

Figure 1: The fabrication process for InPmembrane

waveguides. (a) wafer bonding (b) InP substrate and

InGaAs sacrificial layer removal (c) 1st EBL for

waveguides (d) Waveguide etching (e) 2nd EBL for

gratings (f) Final device after grating etching.

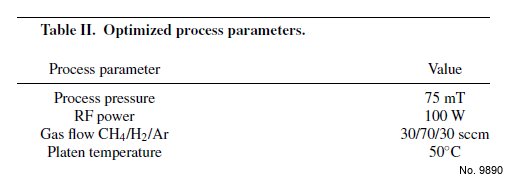

Table 1: Optimized process parameters.