Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

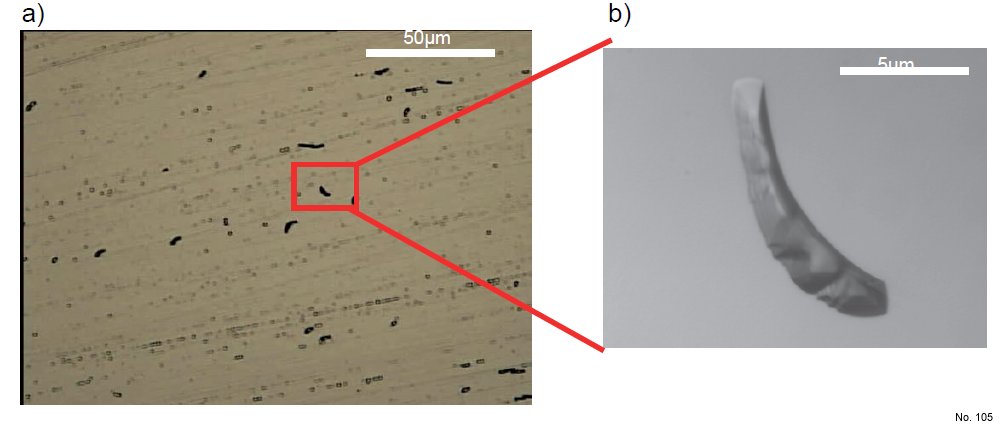

Subsurface Damage Caused by Coarse Grinding

Material Name: Silicon

Record No.: 105

Primary Chemical Element in Material: Si

Sample Type: Wafer

Uses: Grinding

Etchant Name: None

Etching Method: Grinding

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

Note: Coarse grind and fine grind surfaces which are etched for about 60 seconds in 20 wt-

% and 60 °C KOH are shown in Figs 1a and 1b. On the etched surface, it can see

cracks caused by coarse grinding which are enlarged in KOH etching. KOH etchant

penetrates into the cracks and etches the surrounding silicon much faster because in

the crack there are many other crystal planes to attach which etch much faster than

the (100) surface plane. This phenomenon can be seen when the fine grind removal

is too shallow and the subsurface damage caused by coarse grind is not removed

totally in the fine grind process step.

Reference: Petteri Kilpinen, KOH anisotropic silicon

etching for MEMS accelerometer fabrication, PhD Thesis, Aalto University, 2014, pp. 48-49.

Figure 1: Fine-grind silicon surface, preferential etched with KOH (20 wt-% and 60

°C) for 60 s, which still has subsurface damage caused by coarse grinding.