Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Sub Surface Cu Voids

Material Name: Copper

Record No.: 110

Primary Chemical Element in Material: Cu

Sample Type: Layer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

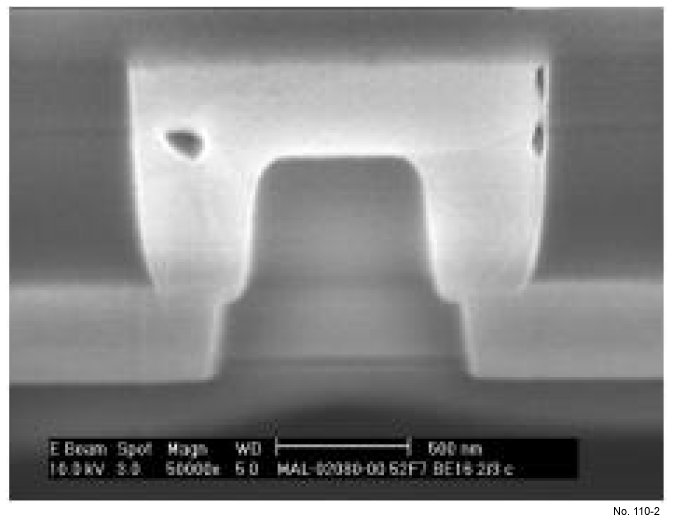

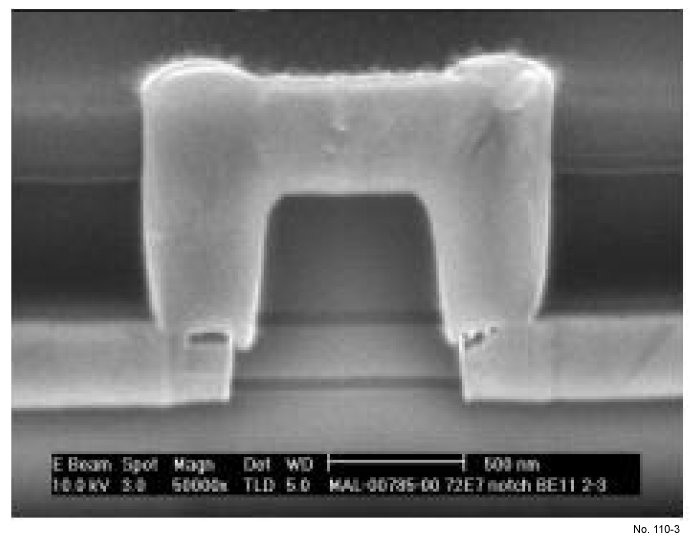

Note: Copper voiding is major headache in the megafab

production of IC's. Copper can form as many as four

different types of voids, necessitating constant vigilance and tight process

control. FIB sectioning of void test structures is a destructive

but effective method to monitor process induced

voids. See Figures (14-16) below. Sub surface Cu voiding is particularly hard to detect

because it neither visible to "top view" KLA-like

inspections and rarely results in a full electrical

opens. Thus slower and destructive techniques are

required to monitor the process. Passive FIB voltage

contrast is especially helpful with well-designed test

structures.

Reference: Bryan Tracy, Materials Analysis and Process Monitoring in MegaFabs, ISTFA 2002, Proceedings of the 28th International Symposium for Testing and Failure Analysis, 3-7 November 2002, Phoenix Civic Center, Phoenix, Arizona, pp. 69-75.

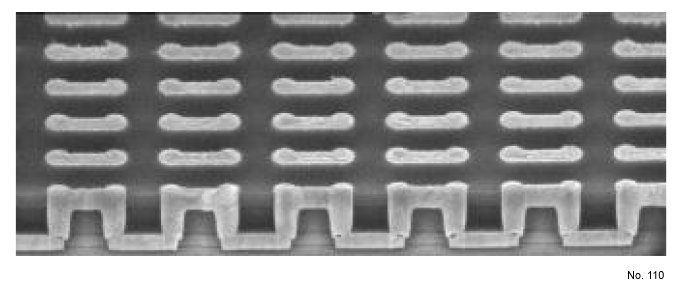

Figure 1: SEM of a M2/M1 via void test structure.

Figure 2: Bulk and via sidewall voids.

Figure 3: Cap interface voids.