Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

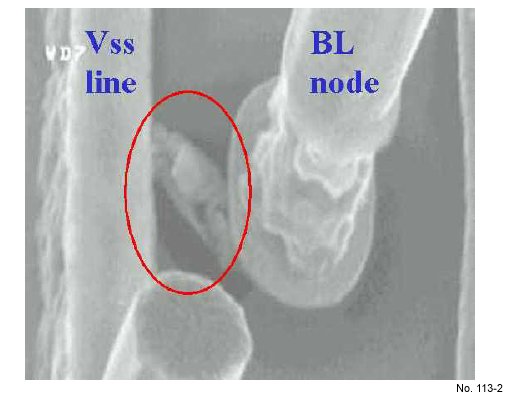

Metal Residue Between BL and VSS-Line II

Material Name: Silicon

Record No.: 113

Primary Chemical Element in Material: Si

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

Note: The device is 0.18 µm process technology, 6-level

metal (4-6 layers are dummy layers) design 2Mb

synchronous SRAM with a single column failure.

The device presents high IDD leakage of 700~800

µA under 2.0V constant voltage.

Experiment shows that OBIRCH cannot find the

fault site from front-side since dummy metal layers

block the laser from the metal layers below. Nikawa

Et al. reported in 1993 that the minimum

temperature could be detected by Hamamatsu

Photonics (emission system) was estimated to be

about 180°C. It is considered to be thermal

radiation. Therefore, the temperature of metallic

short type of defect, which provided leak path, may

have the possibility to reach closely 180°C or higher.

To gain the advantage of front-side analysis,

Hamamatsu photo emission microscope (Phemos

200, a dedicated emission system) was tried to

localize fault site even though it is not expecting to

detect metallic short type of defect.

Reference: Cheng-Piao Lin, Cheng-Chun Ting, Chin-Hsin Tang, Cheng-Hsu Wu, Chih-Ming Kuo,

Yung-Sheng Huang, Application of Various Fault Localization Techniques to Different

Types of 6T-SRAM column Failures, ISTFA 2002, Proceedings of the 28th International Symposium for Testing and Failure Analysis, 3-7 November 2002, Phoenix Civic Center, Phoenix, Arizona, pp. 259-265.

Figure 1: Front-side photoemission image.

Figure 2: SEM image of photoemission located

metal residue between BL node and VSS-line.