Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Missing Metal Pillars

Material Name: Silicon

Record No.: 117

Primary Chemical Element in Material: Si

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

Note: Smaller technologies and increasing chip

functionality has resulted in tightly packed devices

and more stacked metal layers. For technologies

between 0.25 µm and 0.14 µm, stacking packed

metal layers required the combination of Tungsten

plugs as interconnection and the utilization of

Chemical Mechanical Polishing (CMP). “Pillar”,

however, is a small metal line, which allows interlevel

connections between Tungsten plugs. The

size and shape of the pillar can be a yield limiting

issue. The process of identification and resolution

of the missing metal pillar included yield analysis,

electrical and physical failure analysis, root cause

analysis and the engineering coordination of photo

engineering, etch process engineering, CMP

engineering, integration engineering, and inline

inspection. Resolving the missing pillar issue has

proven to have significant contribution to yield.

Reference: Dat Nguyen, et al., Missing Metal Pillar Failure Analysis-A Plug Technology Issue, ISTFA 2002, Proceedings of the 28th International Symposium for Testing and Failure Analysis, 3-7 November 2002, Phoenix Civic Center, Phoenix, Arizona, pp. 267-272.

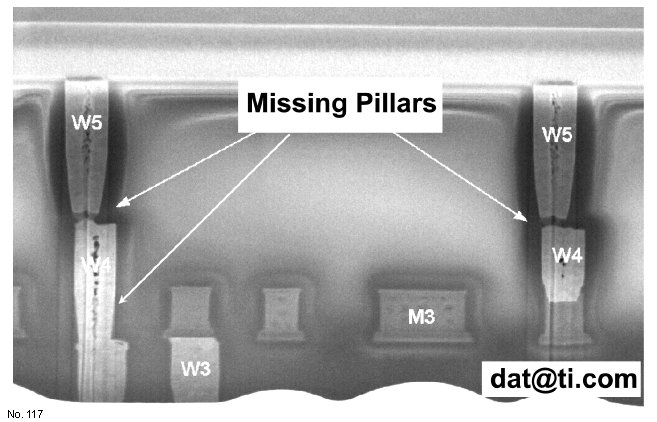

Figure 1: Fault isolation found missing metal pillars.

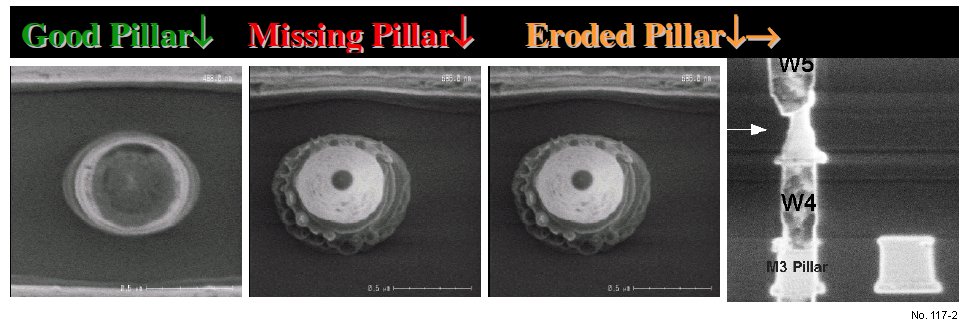

Figure 2: Pillar patterning and metallization.