Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Defect in Digital Micromirror Device

Material Name: Silicon

Record No.: 118

Primary Chemical Element in Material: Si

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

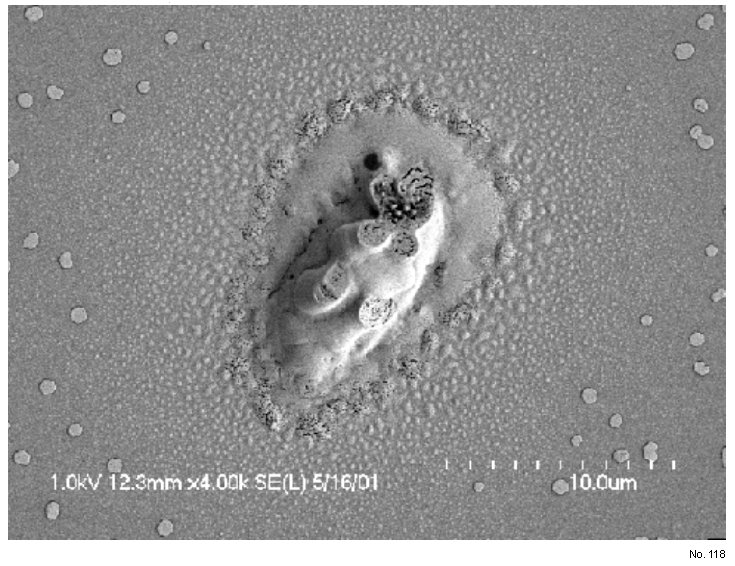

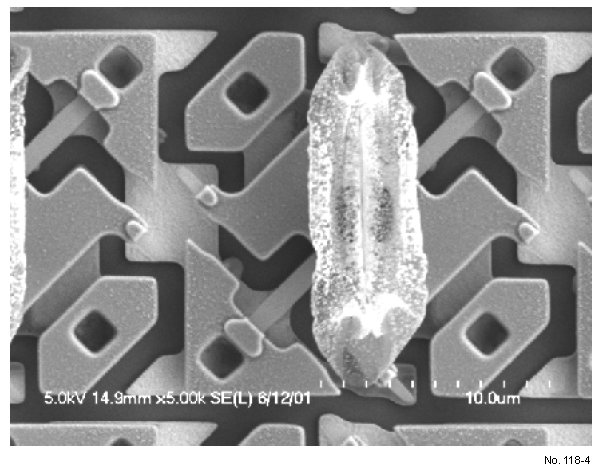

Note: Figure 1 shows just such

trapped carbon-based material that caused the final

image to be less than acceptable. As light travels

through the window, a shadow of the material is cast upon the surface of the mirrors. This shadow is also

transmitted back to the window in reflection, and

therefore is a problem in at least two occurrences. If

the window is observed using a directional light

source that is approaching the unit at an angle

similar to that used in the actual application, a pair

of dark or bright spots will be observed. The window must be removed mechanically before

further analysis is possible within the device. This is

accomplished using methods dependent upon the

type package used. Grinding through seam welds is

the most common method. Extreme care must be

taken to prevent grinding into the operational cavity,

as this will distribute metal particles freely

throughout that cavity and cloud the analysis.

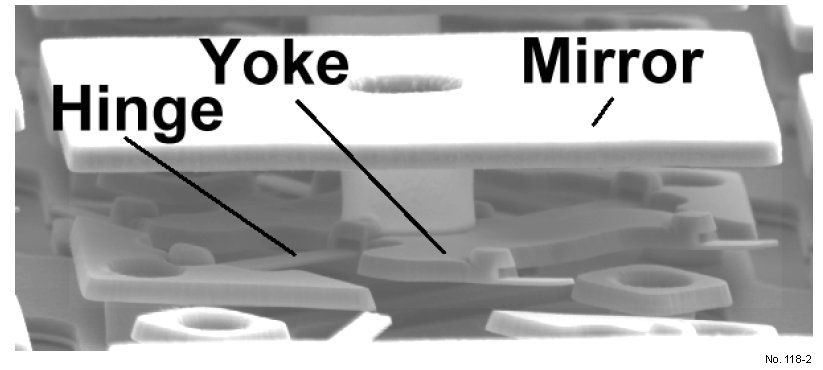

The superstructure required to build a DMD is a 3-D

array of metal and hollow space. Fig. 2 shows this

as seen from an extreme viewing angle.

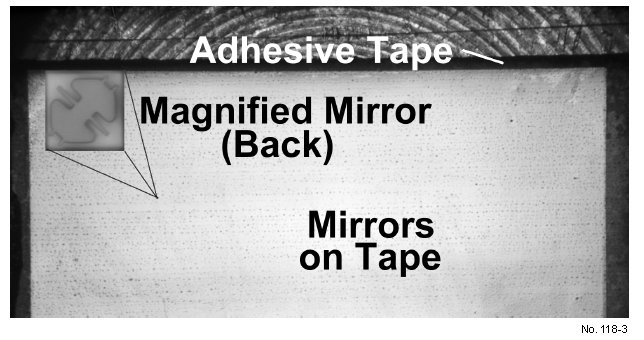

Removal of the mirrors can be carried out by several

methods, but the most common method is exquisite

in its simplicity. Common transparent adhesive tape

is applied carefully to the surface of the mirrors with

a light amount of pressure, then removed in one

motion. With the tape come the mirrors, breaking

the hinges in the process. The view of the

substructure surface is now unobstructed, and on

the tape we removed are all of the mirrors and yokes

available for inspection in an inverted position as in

Figure 4. This image shows the entire area of mirrors removed

using the tape, and an expanded view of a single

yoke/mirror assembly. This is the view offered by

inspecting the rear of the mirrors, usually with a low

accelerating voltage in a Field Emission SEM.

This allows us to inspect the lower surfaces of both

the yokes and mirrors. If reasonable care is taken,

no damage of the substructure surface is observed.

Removal of only the mirrors without damaging the

yokes requires a bit more finesse, and also an

isotropic dry etch. While this is still a global

approach much like the transparent tape method, it

will fold the mirrors and leave the yoke assembly

available for inspection and analysis. This approach

is seen in Figure 6. Similar results are obtainable

using a laser-cutting tool for removing one or more

mirrors. There is some variation in laser power

between units, and therefore each setup must be

worked with to obtain the optimum power and spot

size for single pulse laser mirror removal.

Reference: Cary Davis,Wes Mahin, and Becky Holdford, Failure Analysis of the Digital Micromirror Device, ISTFA 2002, Proceedings of the 28th International Symposium for Testing and Failure Analysis, 3-7 November 2002, Phoenix Civic Center, Phoenix, Arizona, pp. 291-294.

Figure 1: Carbon material which has dried on the

surface of the window.

Figure 2: Typical pixel as seen from extreme viewing

angle.

Figure 4: Tape after mirror removal.

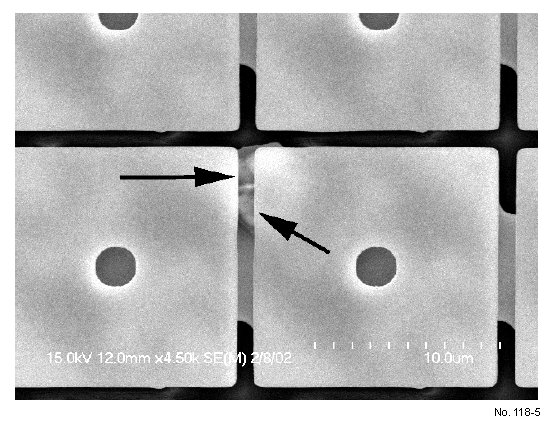

Figure 5: View of material trapped behind the mirror

imaged using High Acceleration Imaging.

Figure 6: Mirror reduced using RIE isotropic etch.