Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Breakdown in Vertical Gate Oxide

Material Name: Silicon

Record No.: 119

Primary Chemical Element in Material: Si

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Wet etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

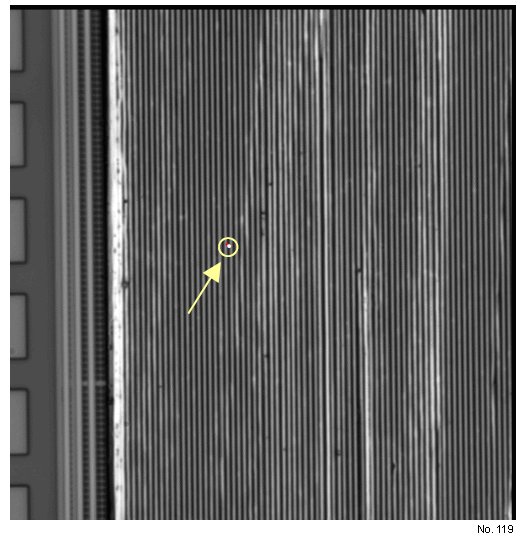

Note: The stress leakage current data does not provide any

location information of the failing transistors. The

PFA flow has to start with localization of the gate

oxide breakdown site. The widely used

photoemission microscopy is used here along with

electrical probing to narrow down the failure site

within some (3-5) transistors along one word line.

Figure 5 shows a photoemission image example.

The sample preparation starts from delayering the

array to the bit line level using mechanical polishing

and etching. Reactive ion etching (RIE) is then used

to remove the dielectric between the bit lines. RIE

etching is necessary here in order to make the word

lines visible in the FIB tool. Alternatively the sample

can be delayered to the word line level, but the area

of interest must be capped with metal to avoid any

damage of the polysilicon within the gate during the

following wet etch. With the limited number of

samples that were processed so far the second

approach resulted in better quality SEM images. The

next step is to remove materials on both sides of the

word line connecting the failing cell through FIB

milling.

A Micrion 9000 FIB was used to perform two crosssections

on both sides of the wordline, as shown in

Figure 6. The figure shows a cross-sectional view of

a vertical transistor cell. This cross section is not part

of the here described preparation flow for the vertical

transistor. It illustrates were the cross-sections which

are used for the vertical transistor remove material

(hatched areas) in order to access the vertical gate

oxide. Figure 6 shows also the range where the actual

cross section can be located (arrow). This range is

about three times as wide as the minimum feature

size since it is only necessary to cut in between two

vertical gates. The remaining silicon is removed by a

wet etch. The material removal was performed with a

step mill followed by a single pass mill, both using a

100pA beam current. The milling box size was in the

range of 3ìm by 3ìm. Since the space between two

trenches is 3 times the minimum feature size (range

of successful cross-section), this cross-section

operation is believed to be applicable down to 110nm

minimum feature size without problems. The final

stage of the preparation is to remove the silicon

surrounding the trenches so that the gate oxide is

exposed for SEM examination. Chemical solution

HNO3:HF (100:1) wet etch was used. Typical etch

time is between 5 and 20 seconds depending on the

location of the FIB cuts. The etch process can be

done in iterations with SEM inspection to find the

exact etch time. The exposed oxide surfaces were

shown to be able to sustain several seconds of

overetching without any visible damages. Past

experience with this etch proofed to be selective

enough and very reliable to expose thin oxides from

Silicon. Figure 7 shows the sample after wet

etching. The vertical transistors along one wordline

are completely exposed. Since multiple transistors

along one wordline can easily be exposed, an exact

prelocalization of the failing transistor is not required

in this direction. Perpendicular to the wordline the

location information is crucial for the success of the

described preparation technique since adjacent word

lines are removed.

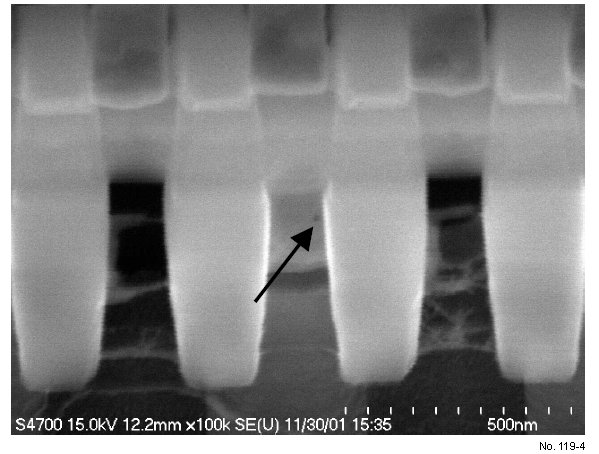

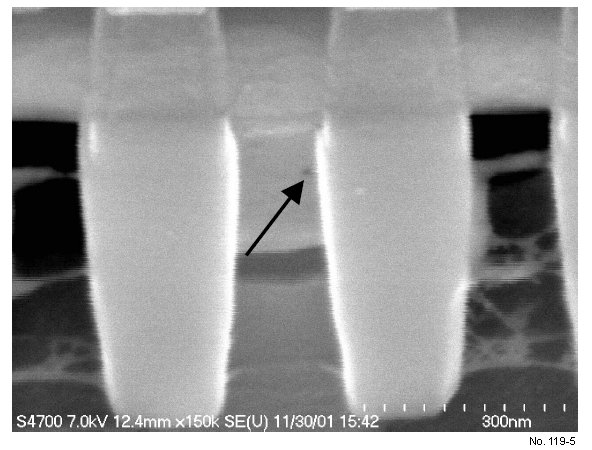

Figure 8 and Figure 9 show a pinhole in the vertical

gate oxide exposed after the described sample

preparation. The gate oxide breakdown spot is not

correlated to any interfaces, which provides

important information for further process

improvements. The dark decoration of the failing gate oxide is

caused by an etch-out effect. The HNO3:HF (100:1)

wet etch reached the gate poly-silicon through the pinhole and etched out some of the poly-silicon

around the pinhole within the gate – leaving a cavity

there. This cavity reduced the secondary electron

emission rate and thus caused the darker appearance

of the failing gate. This is a typical result as expected

for intrinsic gate oxide fails.

Reference: Michael W. Ruprecht, et al., Sample preparation for vertical transistors in DRAM, ISTFA 2002, Proceedings of the 28th International Symposium for Testing and Failure Analysis, 3-7 November 2002, Phoenix Civic Center, Phoenix, Arizona, pp. 307-311.

Figure 5: Photo emission image of gate oxide

breakdown in DRAM array. The emission spot is

visible inside the circled area.

Figure 6: Cross-section of vertical access transistor in

DRAM array.

Figure 7: Exposed vertical transistors after wet

chemical etch.

Figure 8: Breakdown in vertical gate oxide.

Figure 9: Higher magnification of gate oxide

breakdown shown in Figure 8.