Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Misalignment

Material Name: TiN

Record No.: 122

Primary Chemical Element in Material: Ti

Sample Type: Layer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

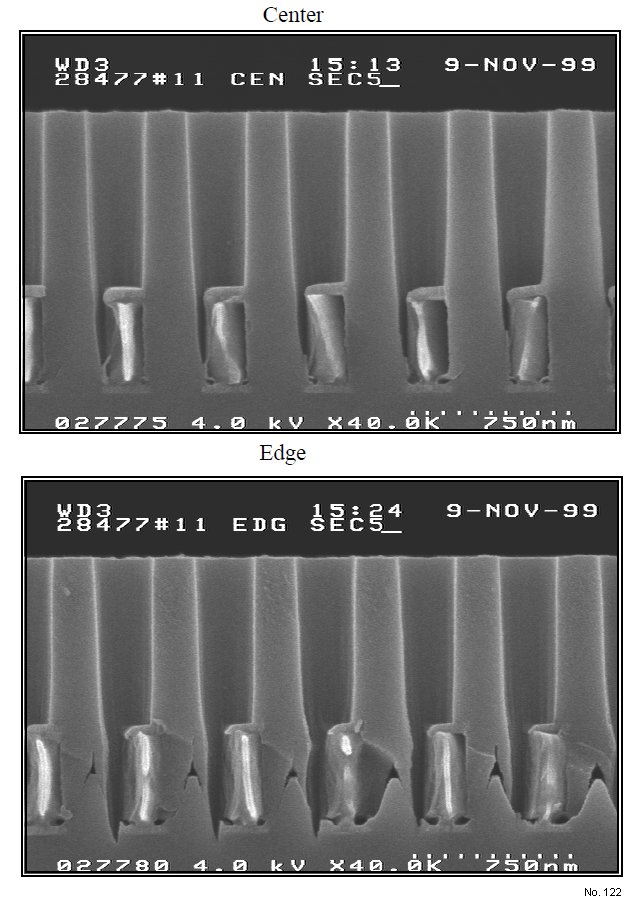

Note: Baseline Recipe: The baseline recipe for the “Stop on TiN” process is set up as the following:

SPARC etch step, Main Etching step. It is also called one step etching process since the

over etching is included in the Main Etching step.

During Main etching step, higher chuck temperature, lower power are explored to

get higher selectivity of oxide to TiN in the beginning of development work. In addition,

the thickness of TiN layer is doubled to have bigger etching process margin. Figure 1

shows the cross-sections of “Stop on TiN” baseline process. The via etching process is

stopped on the TiN layer successfully and the via profile is shaped straightly. The TiN gauging is around 12 nm/14 nm (center/edge) and equals 10% to 20% of the TiN

thickness. The CD bias is less than +/-0.01 µm that is very similar with the BT process.

40% to 50% over-etch without etch stop is obtained from the cross-section SEM pictures

on 18 kA wafers. Much higher selectivity of oxide over TiN is up to 32:1 during the

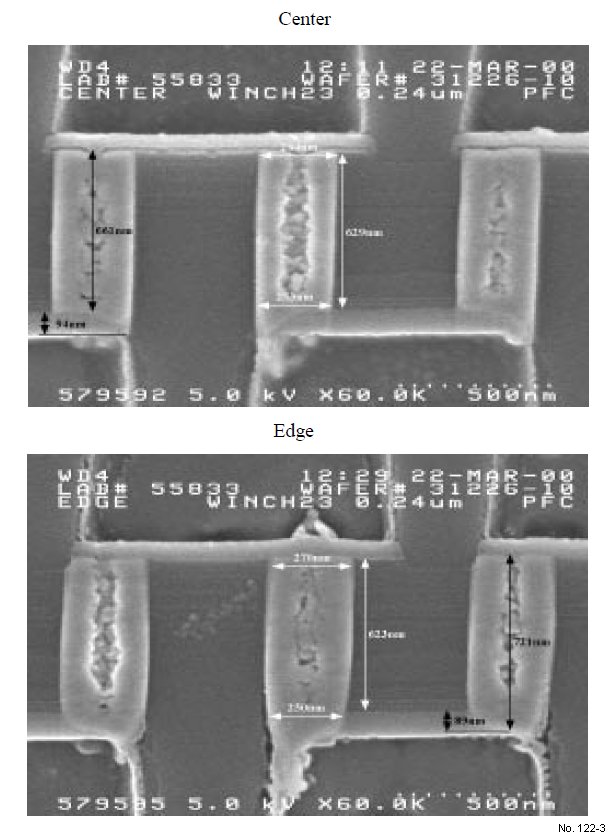

baseline process. It is very interesting to find another issue relative to the process margin

of the photolithography step after the wafer is etched with the baseline etch recipe. The

TiN layer is broken through at the corner of the vias due to the misalignment of the vias.

The chance for the failure of EM is increased dramatically as the break-through process

did before. Figure 2 shows the cross-section SEM pictures for the misalignment vias

after etching and PR strip. Figure 36 shows the cross-section SEM pictures for the same

misalignment vias after W plugs deposited. Both of them obviously indicated that the

misalignment issue should be addressed before the lots go to via etch step. This problem

is solved smoothly after the photo engineers adjust the process margin and reset up the

speciation of the misalignment.

The special experiment is completed to check the etch rate of TiN during main

etching. The method used in here is to have the difference of TiN gauging be divided by

the difference of etch times. At first, some special mechanical wafers need to be prepared

for the experiments. The bare Si wafers are used in here to reduce the development cost.

The 1000 Å TiN layer is deposited on the Si wafers instead of standard TiN thickness.

Then the wafers go through the standard Via Zone Test (VIAZT) routing to have the

regular dielectric layer deposition and the standard photolithography process. The

advantage of these mechanical wafers is that they are very similar with the actual VIAZT

wafers except thicker TiN layer. The more accurate data can be collected on these wafers.

Finally, one mechanical wafer is etched by using the baseline “Stop on TiN”

process, another mechanical wafer is etched one more extra minute compared to the

previous wafer. The difference of TiN gauging can be read accurately from the crosssection

SEM pictures of these two wafers by using the PCI software. The etch rate of TiN

can be calculated by the quotient of the difference of TiN gauging over one minute. The

final TiN etch rate is about 150 Å/min which is very slow compared to the etch rate of

oxide during the main etching. The selectivity of oxide over TiN is obtained after the etch

rate of oxide is divided by the etch rate of TiN.

Reference: JUAN JUAN WANG, ADVANCED PLASMA-ETCHING PROCESSES FOR DIELECTRIC MATERIALS IN VLSI TECHNOLOGY, PhD Thesis, UNIVERSITY OF FLORIDA, 2002, pp. 64-68.

Figure 1: Cross-sections of “Stop on TiN” baseline process.

Figure 2: Cross-sections of “Stop on TiN” baseline process for the misalignment vias

after etching.

Figure 2: Cross-sections of “Stop on TiN” baseline process for the misalignment vias

after W plugs deposited.