Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Wafer Spinning Rate

Material Name: Silicon

Record No.: 124

Primary Chemical Element in Material: Si

Sample Type: Wafer

Uses: Contamination

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

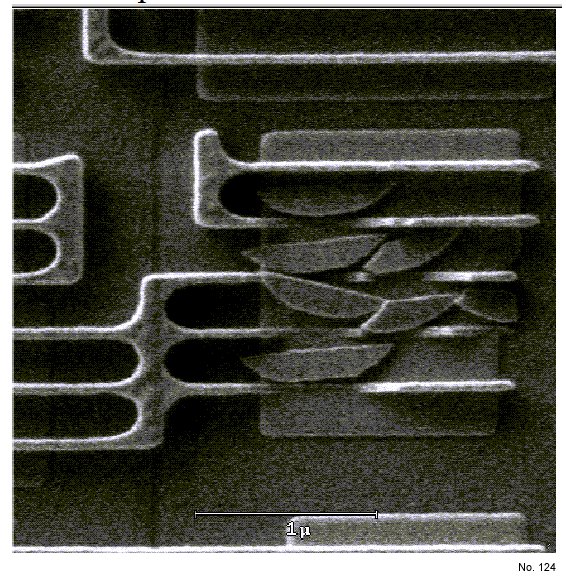

Note: In addition to blocking ion paths into target surfaces, the arrival of

particles onto the surface of rapidly moving wafer s can cause serious impact damage to fine

featured IC device structures (Fig.1). For 200 mm wafers on a spinning wheel with a 1200

mm radius to the wafer center and a 1250 rpm rotation rate, the lateral wafer motion is ~83 m/s.

The impact of a part icle on <0.25 µm wide poly Si lines is sufficient to shatter the structures,

with the extent of damage increasing for smaller device dimensions.

Reference: Michael I. Current, Heiner Ryssel, Chapter 12, Ion Beam Purity and Wafer Contamination, ResearchGate, 2018, https://www.researchgate.net/publication/330357088, pp. 31-32.

Figure 1: Damage to 100 nm wide poly Si lines from particle impacts on a wafer

spinning at ~83 m/s on a spinning wheel end station.