Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Voids - Germanium

Material Name: Germanium

Record No.: 149

Primary Chemical Element in Material: Ge

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

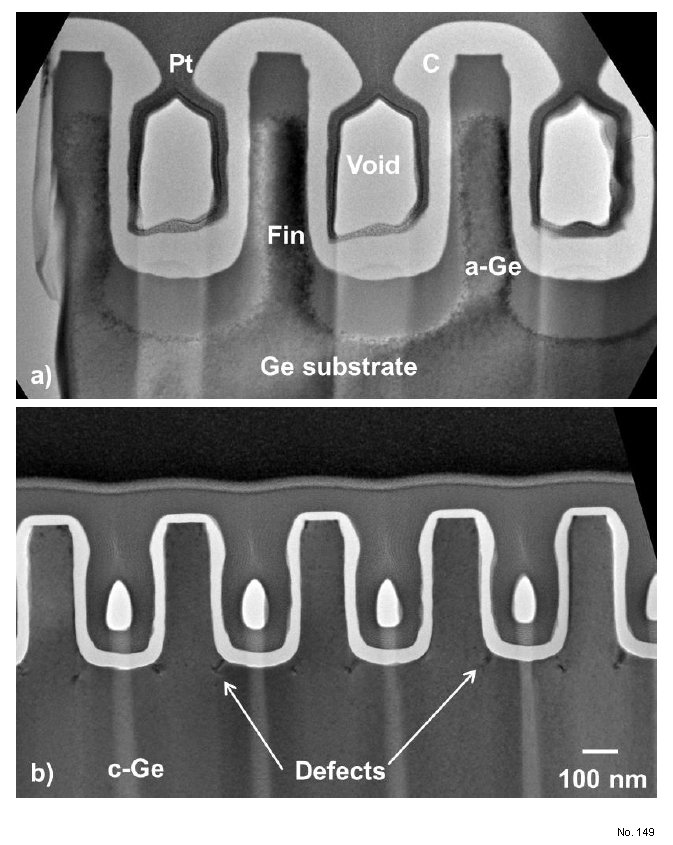

Note: Figure 1 a) shows a TEM image from an array of wide Ge fins where the top

120 nm of the structures was amorphized due to the implantation. In this part of the

experiment the fins are approximately 450 nm tall and 105 nm wide. Narrow fins

with 20-25 nm width were completely amorphized under the same implant

conditions. In the following, bright-field TEM images homogeneous gray regions

are amorphous Ge and dark features are defects. The shown images are a

representative selection of a larger set of images. The intrinsic Ge recrystallization

rate is ~ 2 nm/s for 400 °C anneal, therefore after 3 minutes all the Ge is

expected to be recrystallized. Fins are partially amorphized on the top and in the

trench. Deposited carbon and platinum layers are also seen in the image. Figure 1 b) illustrates the fins after a 400 °C 3 min anneal where SPE is complete.

Reference: Maryam Shayesteh, Novel Processes, Test Structures and Characterisation for Future Germanium Technologie, PhD Thesis, NationalUniversityof Ireland, Cork, 2014, p. 117.

Figure 1: XTEM image of Ge fins, a) partially amorphized after implant. b) Although SPE is

complete, defects and twin boundaries are generated.