Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

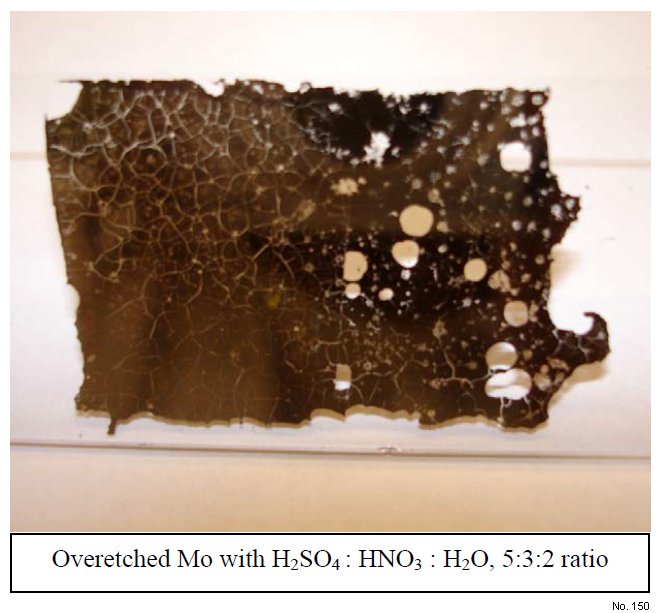

Overetched Mo with H2SO4 : HNO3 : H2O, 5:3:2 Ratio

Material Name: Mo

Record No.: 150

Primary Chemical Element in Material: Mo

Sample Type: Thin film

Uses: Etching

Etchant Name: None

Etching Method: Wet etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

Note: Because there was no pre-made

solution for molybdenum wet etching,

several recipes had to be tested. The

first recipe involved a combination of

H2SO4, HNO3, and water. The problem

with this solution was that the etching

was too fast and too strong (at a ratio

of 5:3:2, respectively), and the first

couple attempts showed that the

solution actually penetrated through

the photoresist layer. Even when the

concentration of H2SO4 and HNO3

were diluted by adding more water, the

etching was still too fast for the

purposes of this experiment.

After multipletries,a reasonable etch ratio was found: 30 mL H3PO4, 18 mL HNO3, 10 mL CH3COOH, 65 mL H2O. The etch rate for this solution was approximately ~40 Å/s.

Reference: Jim Tai, Sputtering, Electrical Conductivity and Wet Etching of Molybdenum Films, 2007, https://w3.pppl.gov/ppst/docs/tai.pdf.

Figure 1: Overetched Mo with H2SO4 : HNO3 : H2O, 5:3:2 ratio.