Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Pinholes Developed in the SiO2

Material Name: SiO2

Record No.: 160

Primary Chemical Element in Material: Si

Sample Type: Layer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

Note: No data

Reference: Owen Cherry, Fabrication of an Atom Chip for Rydberg Atom-Metal SurfaceInteraction Studies, MSc Thesis, University of Waterloo, Ontario, 2007, p. 109.

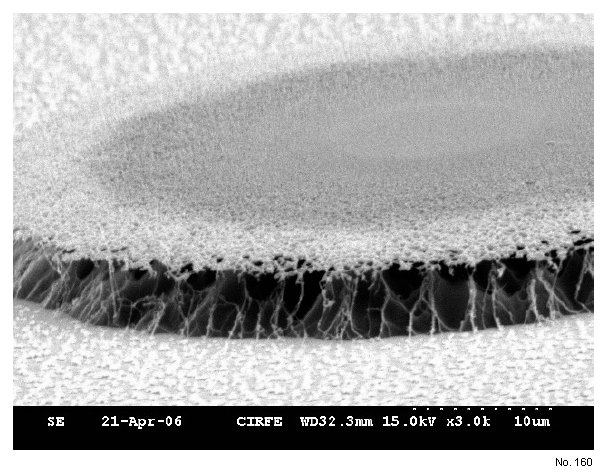

Figure 1: SEM image of a polyimide PI 2611 film etched in O2 using a SiO2 etch mask. During the

etch, pinholes developed in the SiO2, causing a highly undercut film with rough edges. An Al etch

mask consitently gives smooth edges with less undercut.