Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Poor Salicide Coverage

Material Name: Silicon

Record No.: 164

Primary Chemical Element in Material: Si

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Wet etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

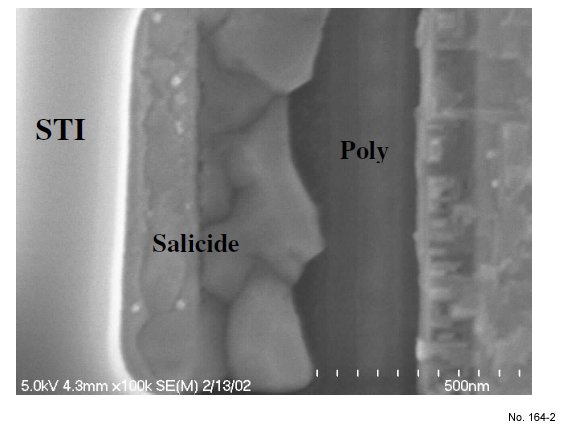

Note: While developing a new salicide for a CMOS

manufacturing process, this technique proved to be

helpful in solving some initial yield problems.

Front-side analysis was difficult because floating

away the metal layers with HF often destroyed the

salicide before it could be inspected. The backside

technique, however, allowed selective removal of

the bulk silicon without compromising the layer of

salicide. Once the bulk silicon was removed,

islands of shallow trench isolation (STI) remained.

The layers of salicide and the gate oxides located between the STI layers remained intact. The

selectivity of the TMAH left the salicide

undamaged as seen in Figures 1 and 2.

Reference: Seth Prejean, Victoria Bruce, Joyce Burke, CMOS Backside Deprocessing With TMAH / IPA as a Sample

Preparation Procedure for Failure Analysis, ISTFA 2002, Proceedings of the 28th International Symposium for Testing and Failure Analysis, 3-7 November 2002, Phoenix Civic Center, Phoenix, Arizona, pp. 370-323.

Figure 1: Backside of transistor with poor salicide

coverage.

Figure 2: Non-uniform salicide grain formation

from the backside.