Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

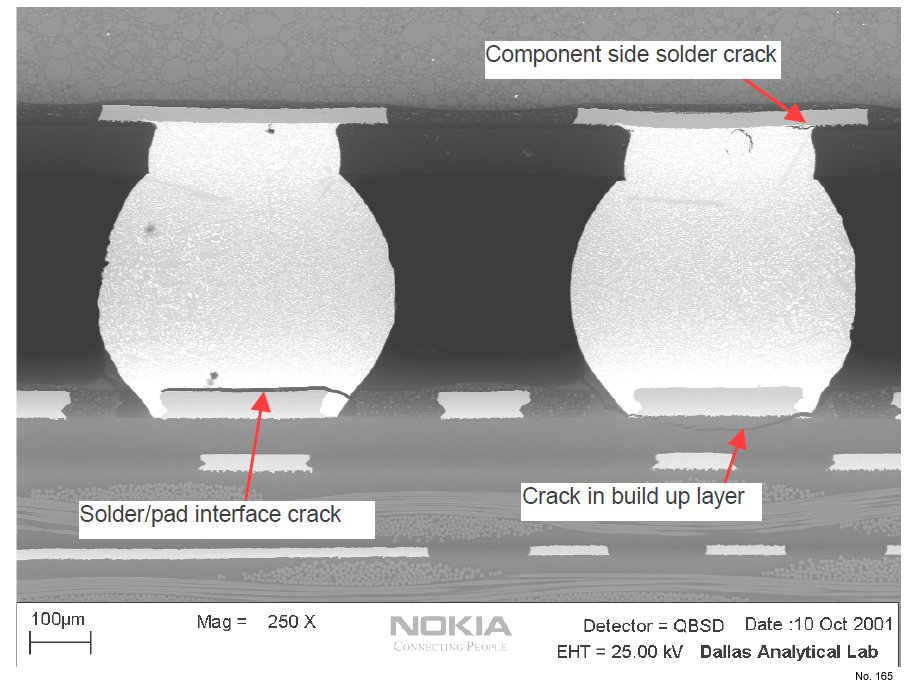

Solder/Pad Interface Crack

Material Name: Solder

Record No.: 164

Primary Chemical Element in Material: (Cu)

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Wet etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

Note: No data

Reference: Sridhar Canumalla, Santosh Shetty and Nael Hannan, Effect of Corner Underfill Voids on Chip Scale Package (CSP)

Performance under Mechanical Loading, ISTFA 2002, Proceedings of the 28th International Symposium for Testing and Failure Analysis, 3-7 November 2002, Phoenix Civic Center, Phoenix, Arizona, pp. 361-370.

Figure 1: Image of an improperly underfilled sample that failed in the simulated end use test is representative of the

population. Cracks were observed under the pad, at the solder/pad interface and in the solder near the component.