Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Process Defect

Material Name: Solder

Record No.: 166

Primary Chemical Element in Material: (Cu)

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Wet etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

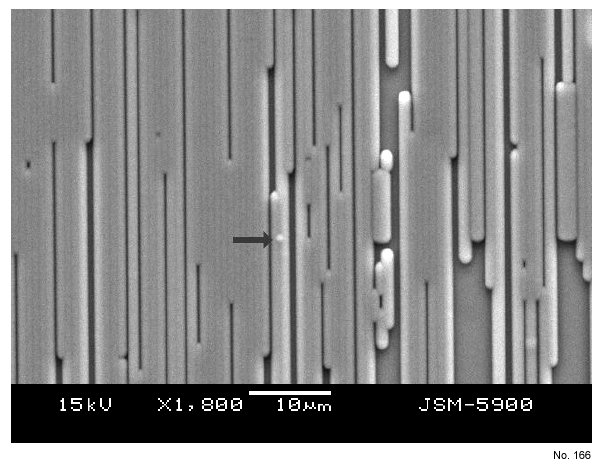

Note: A top view SEM image of the process defect is shown

in Figure 8. This SEM image was rotated by 90 degree

comparing to the microscopic image as shown in

Figure 6.

Reference: William Xia, Leakage Isolation of Mixed-Signal Devices at Operating Modes, ISTFA 2002, Proceedings of the 28th International Symposium for Testing and Failure Analysis, 3-7 November 2002, Phoenix Civic Center, Phoenix, Arizona, pp. 371-376.

Figure 7: As a comparison to device B, the same

area was shown (as pointed by an arrow) from a

known good device (without the process defect as

observed in device B).

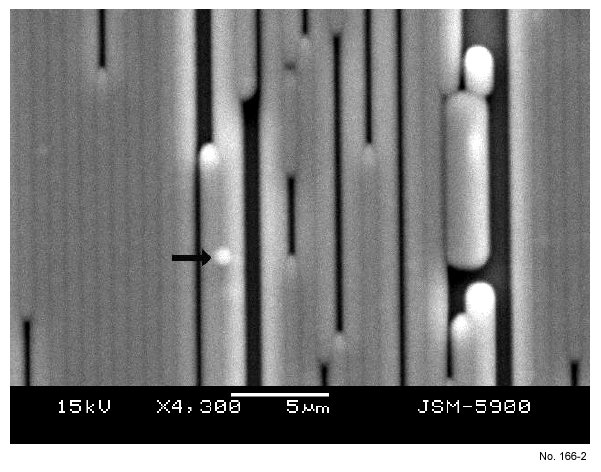

Figure 8: SEM photo of the process defect (as

pointed by an arrow) at the emission site for

device B). This SEM photo was rotated by 90

degree comparing to the microscopic image (in

Figure 6).

Figure 9: A closer look of the process defect at the

emission site for device B (as pointed by an

arrow), which was located between the two

narrowly spaced metal lines.

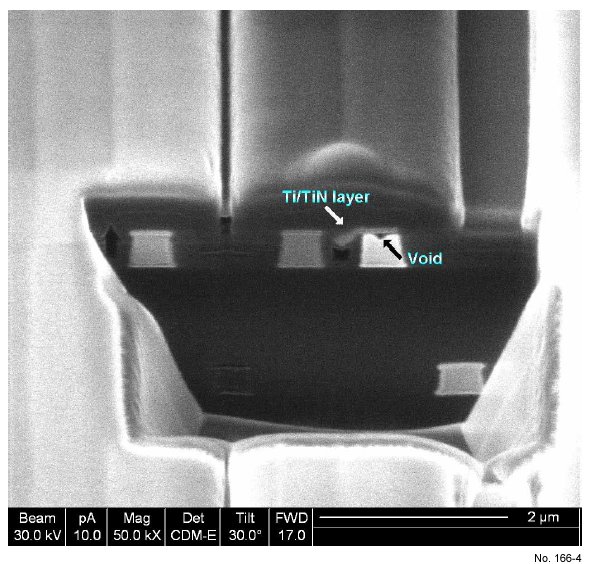

Figure 11: SEM image of the FIB cross-section at

the small process defect between the two adjacent

metal lines revealed a thin Ti/TiN barrier metal

stringer over the two narrowly spaced metal lines

and a void in aluminum metal under the Ti/TiN

layer (as pointed by the arrows).

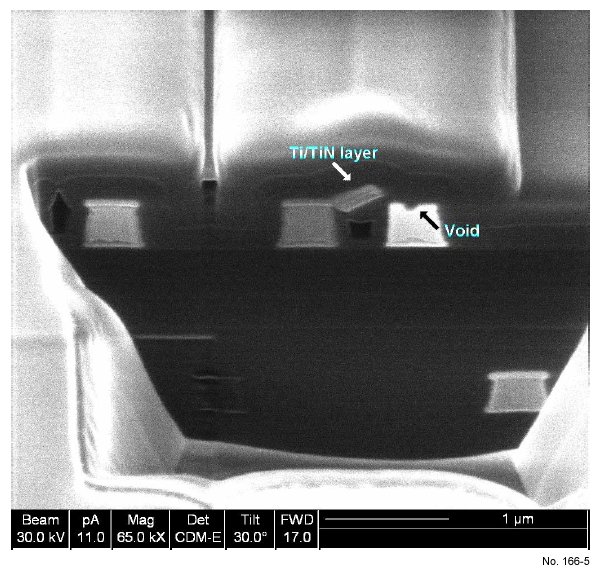

Figure 12: The Ti/TiN metal stringer was found to

extend over to the adjacent metal line on the left

side (as pointed by an arrow) as further FIB crosssectioning

was performed across the small process

defect.