Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Voids in Solder Ball

Material Name: Solder

Record No.: 168

Primary Chemical Element in Material: (Cu)

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Wet etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

Note: No data

Reference: Sridhar Canumalla, Hee Dong Yang, and Puligandla Viswanadham, Method for Measuring Package to Board Interconnection Shear Strength

for Area Array, Fine Pitch Packages, ISTFA 2002, Proceedings of the 28th International Symposium for Testing and Failure Analysis, 3-7 November 2002, Phoenix Civic Center, Phoenix, Arizona, pp. 377-384.

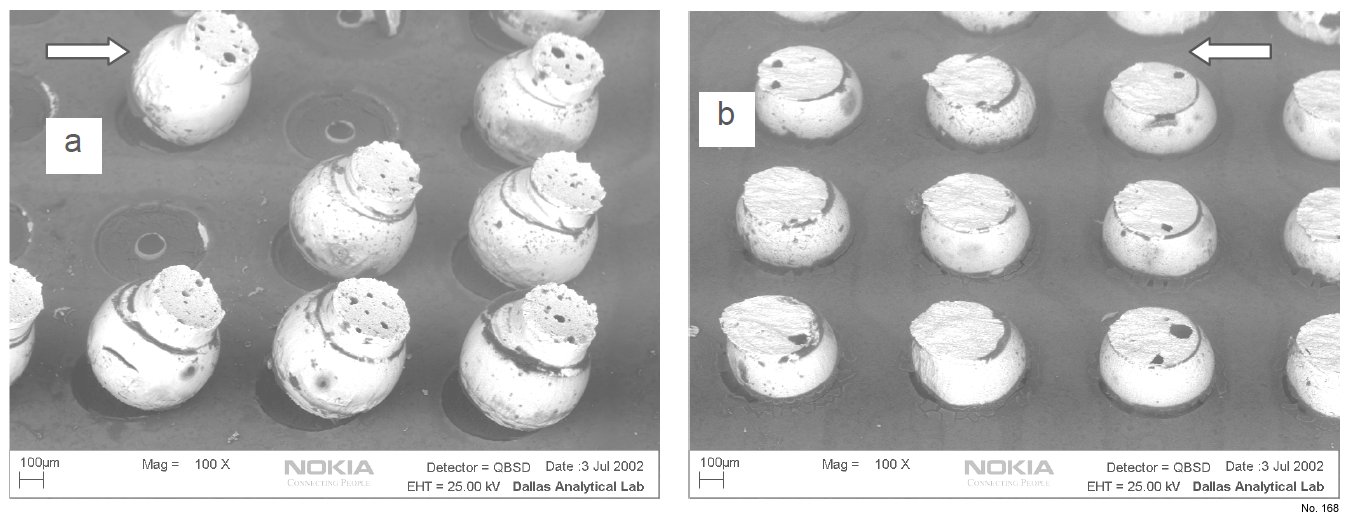

Figure 1: Scanning electron micrograph showing the location of the predominant fractures in a) C1 and b) C2.

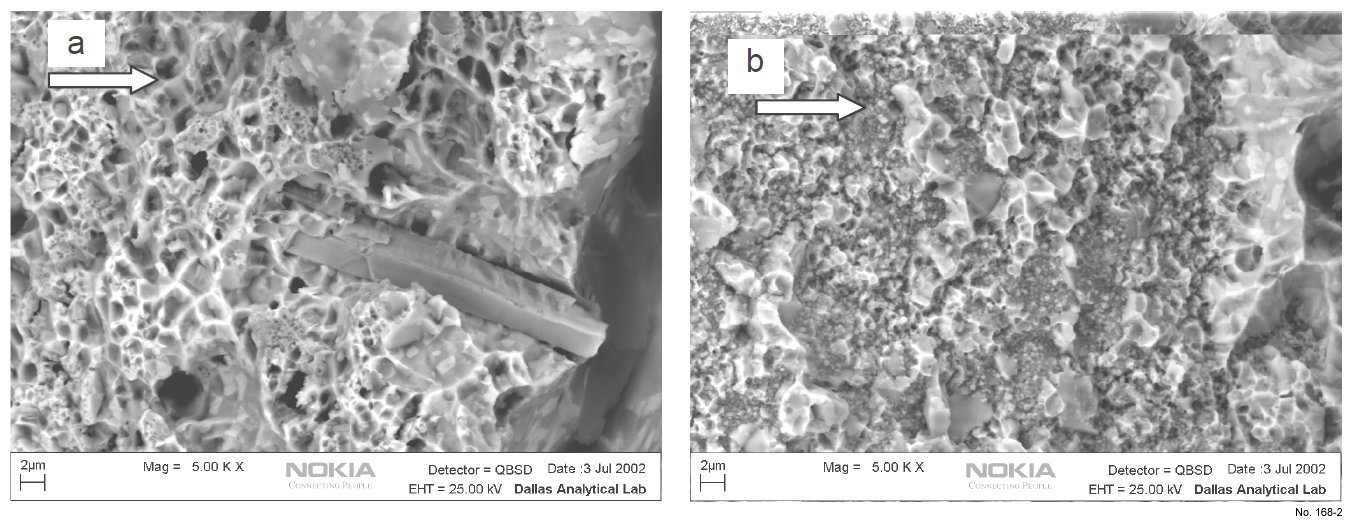

Figure 2: Dimples on a) solder ball side b) component pad side of a C1/S3 sample. These equiaxed dimples signifying

ductile fracture under a locally tensile stress field are observed on both sides of the fracture surface Arrows show the

direction of shearing force.