Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Failure Modes IKnduced by Tin Whiskers

Material Name: Whiskers

Record No.: 170

Primary Chemical Element in Material: Sn

Sample Type: Bulk

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

Note: No data

Reference: Jocelyn P. Siplon, et al., Tin Whiskers On Discrete Components: The Problem, ISTFA 2002, Proceedings of the 28th International Symposium for Testing and Failure Analysis, 3-7 November 2002, Phoenix Civic Center, Phoenix, Arizona, pp. 421-434.

Figure 1: A few examples of pure tin-plated components that have exhibited tin whisker growth, courtesy of

NASA-Goddard.

Table 1: Equipment failure modes induced by tin whiskers.

Table 2: Reported field problems induced by tin whiskers.

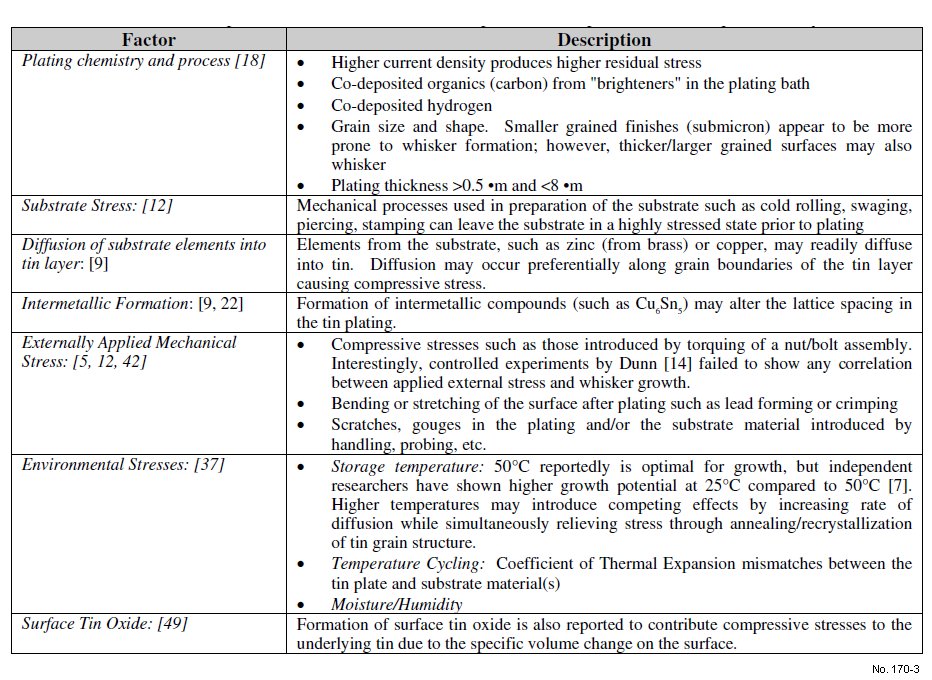

Table 3: Factors reported to contribute to the development of compressive stress in plated tin layers.

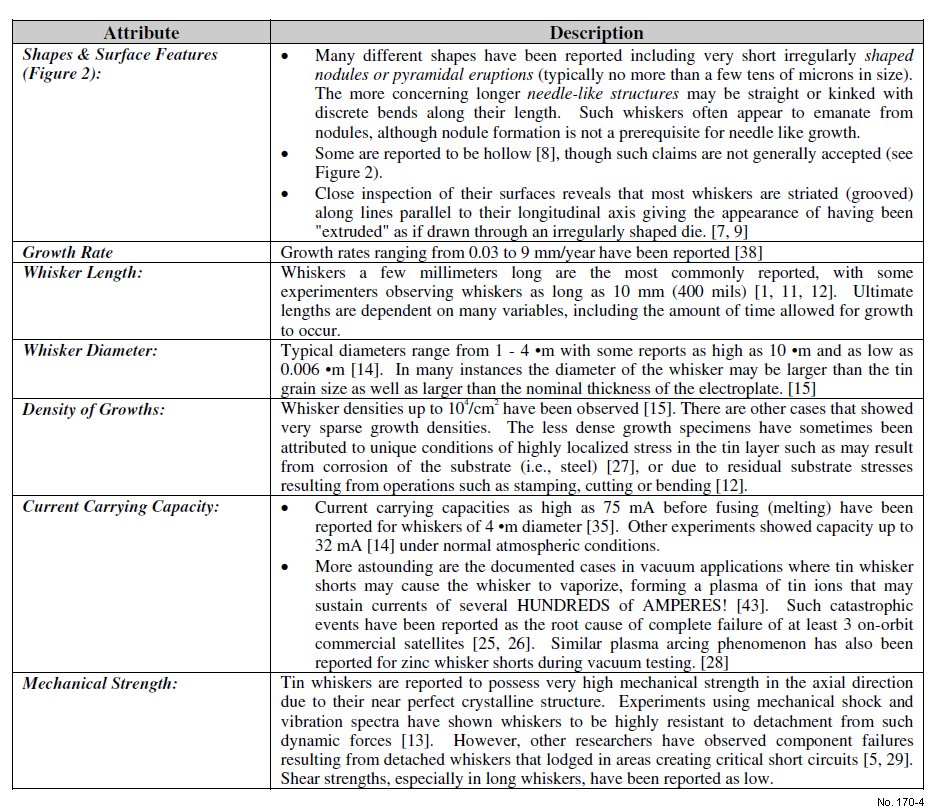

Table 4: Common tin whisker attributes.

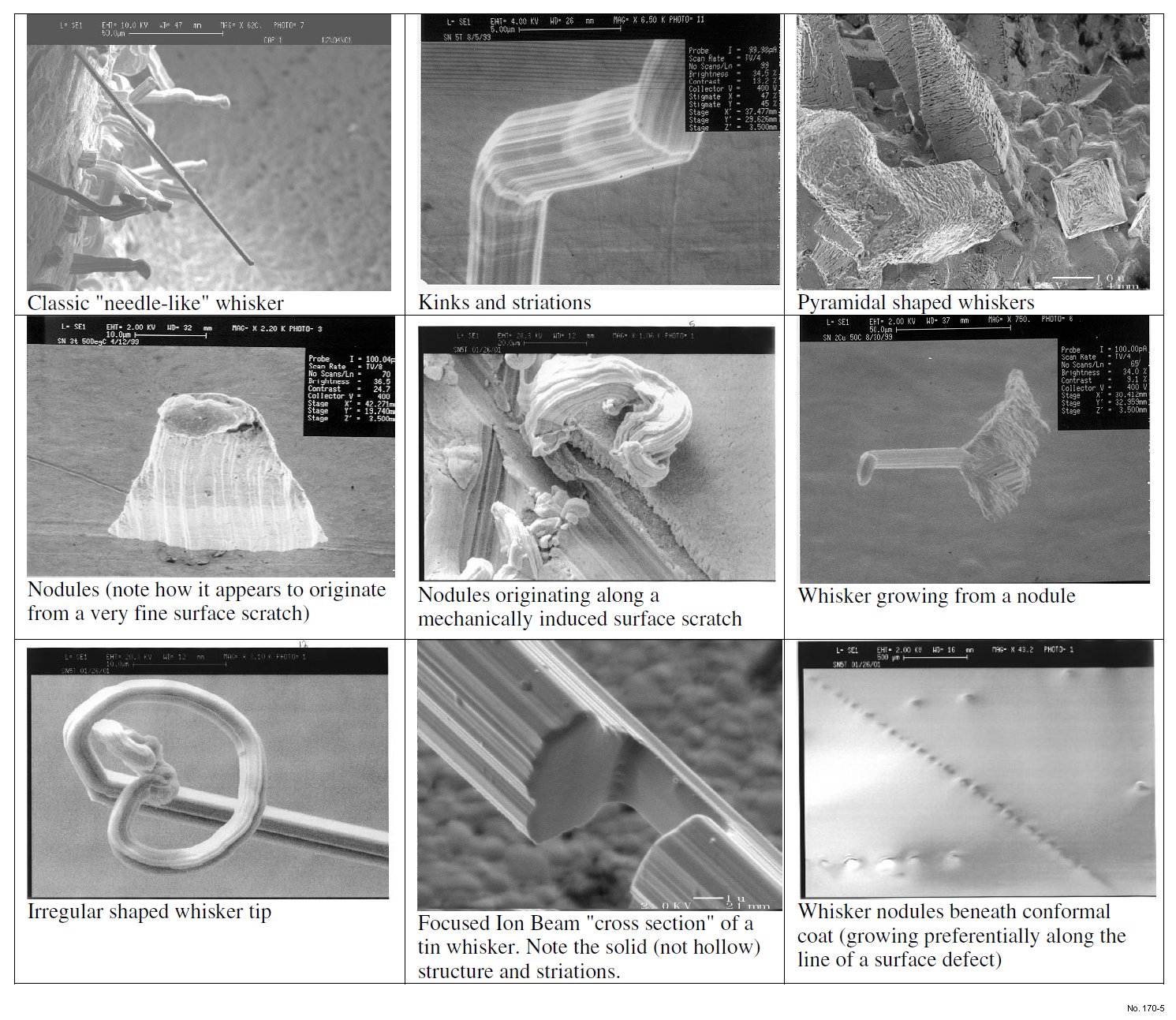

Figure 2: Whisker Shapes (courtesy of NASA Goddard and The Aerospace Corporation).

Figure 3: Tin whiskers/nodules on commercial-grade ceramic capacitor after 554 thermal cycles.

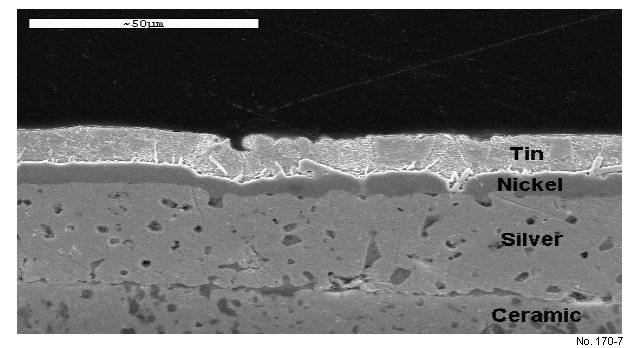

Figure 4: Cross-section of commercial-grade ceramic capacitor with pure-tin termination finish.

Figure 5: Whiskers on MIL-grade pure-tin plated ceramic capacitor after 100 thermal cycles.