Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Kirkendall’s Voids

Material Name: Solder

Record No.: 173

Primary Chemical Element in Material: Cu, Sn

Sample Type: Wafer

Uses: No data

Etchant Name: None

Etching Method: No data

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

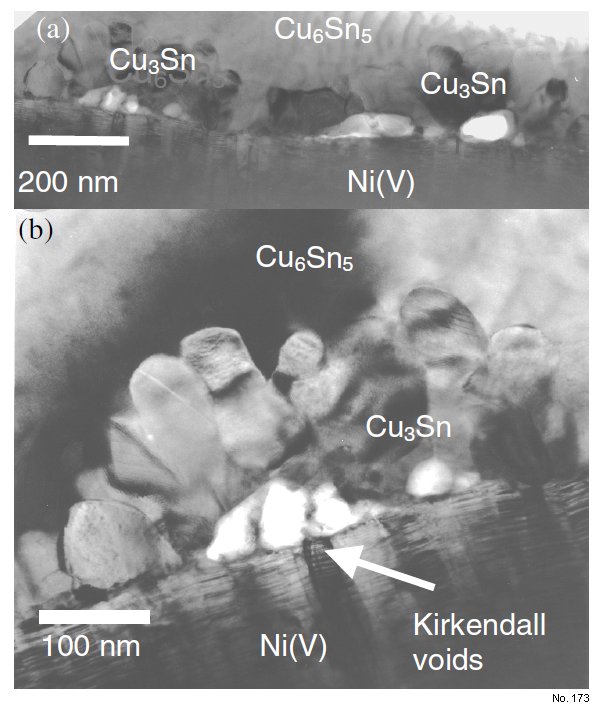

Note: Cross section TEM (XTEM) on the UBM pad

without solder showed the original Cu coating

thickness is about 500 nm. In the as-received

sample (which has already been reflowed once),

Cu layer has reacted to form Cu6Sn5 and Cu3Sn

compounds. The Cu3Sn phase is small grains

aggregated at the Ni(V) interface and mostly

within large Cu6Sn5 grains. Kirkendall voids are

accompanied and wrapped by Cu3Sn phase, as

shown in Fig 1. As reported previously, the

concave nature of the Cu6Sn5/Cu3Sn interface

strongly suggested the reaction is going toward

the Cu6Sn5 phase. Samples after reflow up to

10X did not show any major change in

microstructure. Both Cu6Sn5 and Cu3Sn

remained after 10 reflow cycles.

Reference: Chih-Hang Tung, et al., Microstructure Studies of Under Bump Metallization Systems

Using Transmission Electron Microscopy, ISTFA 2002, Proceedings of the 28th International Symposium for Testing and Failure Analysis, 3-7 November 2002, Phoenix Civic Center, Phoenix, Arizona, pp. 505-511.

Figure 1: Cross section TEM on the as reflow Ni(V) UBM system showing Cu6Sn5, Cu3Sn intermetallics, and Kirkendall’s voids.