Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

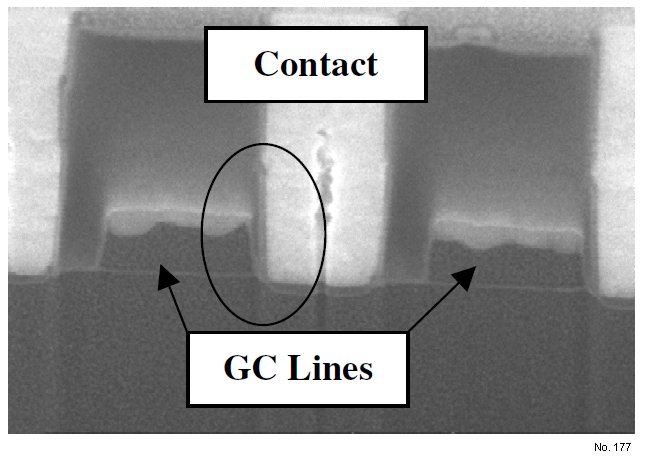

Gate Conductor (GC) Short

Material Name: No data

Record No.: 177

Primary Chemical Element in Material: No data

Sample Type: Wafer

Uses: No data

Etchant Name: None

Etching Method: No data

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

Note: Liquid crystal hotspot analysis and emission

microscopy were employed to localize the defect, but

no significant information could be gleaned from

these methods. As a result, detailed circuit layout

review coupled with layer by layer deprocessing and

cross-sections were used to isolate the fail. Cross-sections

in the suspect area showed that certain

isolated gate lines were much wider than expected,

resulting in a substantial loss of alignment margin,

and thus a high probability of contact to GC shorts,

see figure 1.

Reference: Luis Andrade, Timothy Bynum, Richard Doyle, Brian Flaherty, David Grammer, Chris Jacobs,

Mark Luzar, Eric McDaniel, Dave Ricks, Randall Stanley, Tom Taylor, Targeted Defect Analysis for Yield Improvement, ISTFA 2002, Proceedings of the 28th International Symposium for Testing and Failure Analysis, 3-7 November 2002, Phoenix Civic Center, Phoenix, Arizona, pp. 571-577.

Figure 1: Cross-section image showing a contact to gate conductor (GC) short.