Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Unfilled Contact

Material Name: No data

Record No.: 178

Primary Chemical Element in Material: No data

Sample Type: Wafer

Uses: No data

Etchant Name: None

Etching Method: No data

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

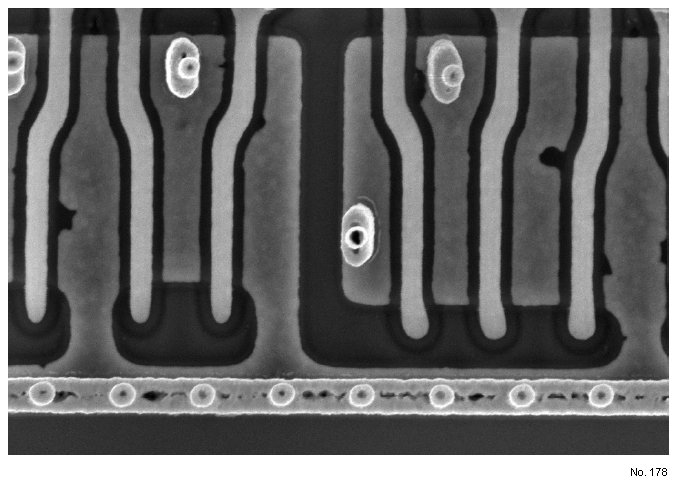

Note: Figure 1 shows a SEM photograph of the

defect found on the unit with successful FA. The

defect was an unfilled contact, with an intact liner.

This defect was not found by inline inspection

because all contacts are unfilled at the time of the

inspection, therefore at that inspection layer, the

contact would not have looked defective. Defects such as this help to explain a low OHR, however,

continued physical FA efforts are ongoing and will

be needed to improve the OHR. Because the OHR is

a direct measure of inline inspection capability and

thus the short loop yield enhancement capability, it is

perhaps the single most important result from the

logic mapping process.

Reference: Brady R. Benware, Driving Baseline Yields on ASICs using Logic Mapping, ISTFA 2002, Proceedings of the 28th International Symposium for Testing and Failure Analysis, 3-7 November 2002, Phoenix Civic Center, Phoenix, Arizona, pp. 579-586.

Figure 1: SEM picture of an un-filled contact defect obtained through PFA.