Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

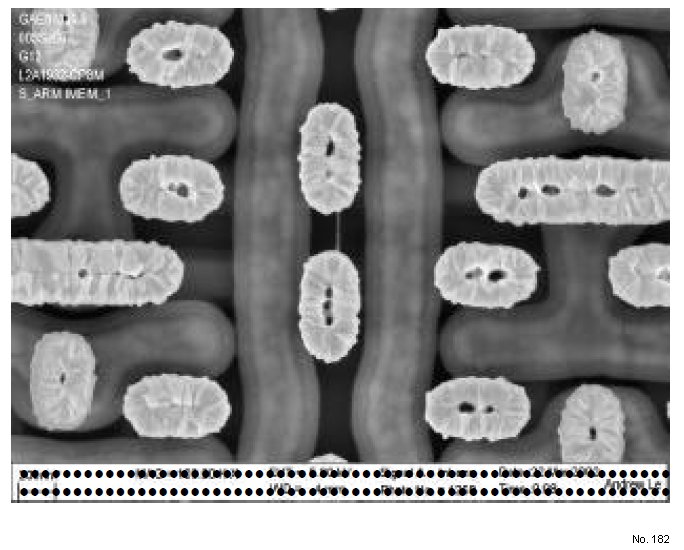

Tungsten Stringer Between Center Contacts

Material Name: Solder

Record No.: 182

Primary Chemical Element in Material: Cu

Sample Type: Wafer

Uses: No data

Etchant Name: None

Etching Method: No data

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

Note: Figure 1 is photograph of a Tungsten

stringer defect discovered in failure analysis of a

minV(DD) outlier for a LSI Logic ASIC. The FA chip

was screened as an SPP outlier of the wafer’s intrinsic

minV(DD) distribution. This is an outlier from the

first step of the feed-forward minV(DD) test.

Reference: W. Robert Daasch, Parametric Variation or Defects?

Statistical Post-Processing Analysis of Wafer-Sort Data, ISTFA 2002, Proceedings of the 28th International Symposium for Testing and Failure Analysis, 3-7 November 2002, Phoenix Civic Center, Phoenix, Arizona, pp. 703-712.

Figure 1: Failure Analysis of a minV(DD) outlier. Defect is the Tungsten stringer between center contacts.