Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Gate Oxide Defects

Material Name: Silicon

Record No.: 184

Primary Chemical Element in Material: Si

Sample Type: Wafer

Uses: No data

Etchant Name: None

Etching Method: No data

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

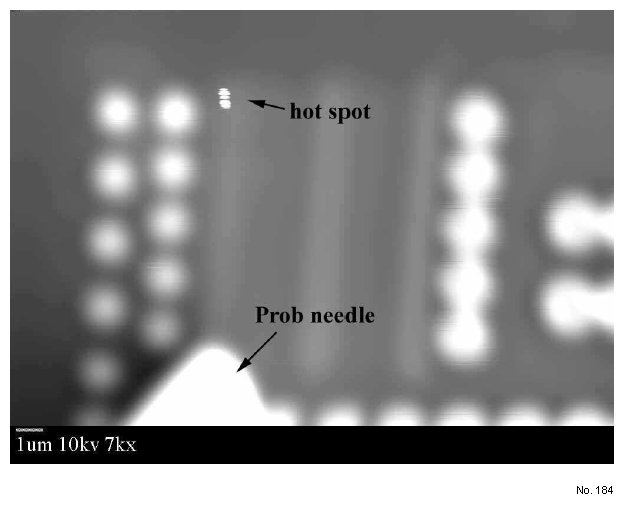

Note: Figure 6 shows the EBIC hot spots

at the upper left side of the image.

Combining a large viewing area and high

resolution, PTEM can be used for defect

searching and final observation. Figures 7, 8 and

9 show three PTEM images, each of them

addressing a different failure mechanism.

The first image reveals a particle on the silicon

substrate and the damage that particle caused.

The particle and the damaged area show different

contrast. Comparing this image with the XTEM

image in Figure 10, it can be seen that the PTEM

in this instance is better able to determine the

size and shape of the defect. The XTEM, on the

other hand, gives us a better perspective on its

exact position relative to the field oxide edge.

This type of defect is due to Kooi oxide, and is a

silicon-nitride residue on the silicon substrate.

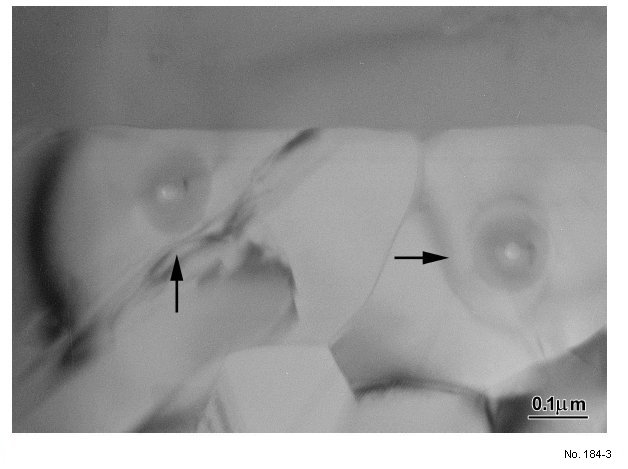

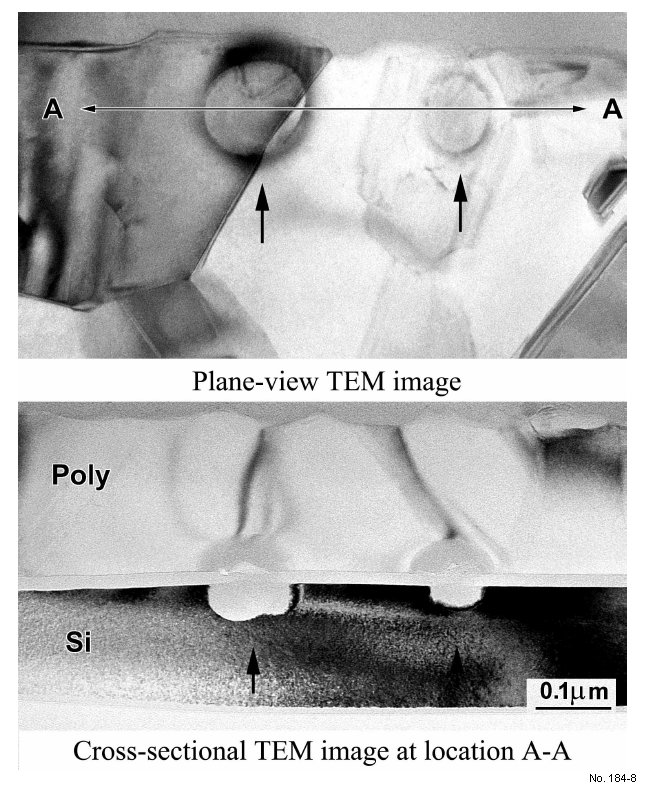

The second PTEM image shows two gate oxide

pinholes. Keeping in mind that bright contrast in

the TEM means low atomic density, the bright

spot at the center of each pinhole indicates a

“hollow” core, and the dark ring indicates the

damaged substrate and poly. Examining the

image closely, in actuality we observe two

concentric rings. In the XTEM image we will

learn that one ring demonstrates the damaged

area in substrate and the other indicates the

damage are in poly. Again, the large area view of

the PTEM approach is useful for such multidefects

cases such as gate oxide damage

resulting from ESD events.

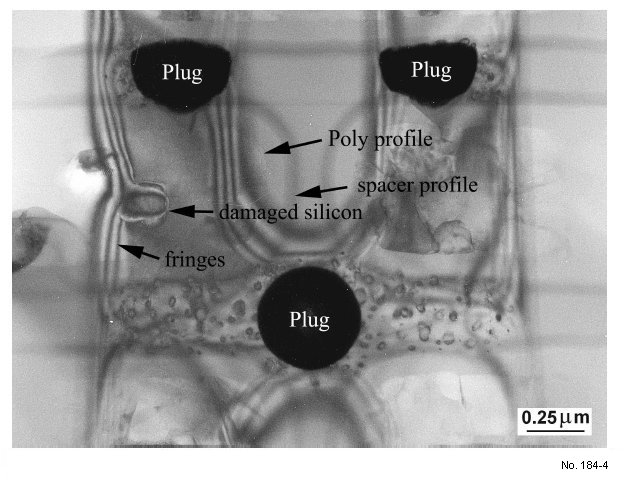

Figure 9 shows a crystal originated pit (COP).

These are imperfections in the silicon crystal,

and may result not only in yield but also

reliability failures, as the inferior quality gateoxide

locally breaks down over time.

The TEM fringe patterns can be interpreted as

thickness contours. In this image, the H-shaped

fringes delineate the active areas. A nodule like

defect can be seen at the edge of the gate. The

polysilicon gates and nitride spacer profiles can

also be observed as light “shadows” in the

image, while the high density tungsten plugs are

entirely opaque and thus readily discernible.

Although PTEM is great for searching and

finding the defect, localizing it on the silicon

plane, and measuring its total size and density,

Fab and R&D engineers typically prefer xsectional

views through the defect, which

provide precise layer and compositional

information. Figures 10, 11 and 12 are XTEM

images corresponding to each of the three defect

types discussed in figures 7, 8 and 9.

These images clearly demonstrate the layer that

defect is located in, and the damage it caused.

In Figure 10, the particle is on the silicon

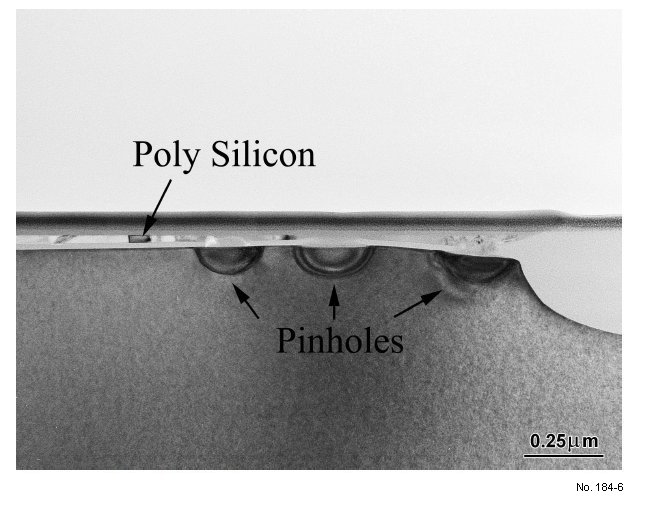

substrate. Figure 11 shows the gate oxide

pinholes. The sample was parallel lapped and the

defect was located with EBIC (figures 5 and 6).

Because the sample has to be lapped down to the

poly layer to allow for a probe needle to touch it,

this sample has very thin poly layer. In this

image we can see the damage on silicon

substrate but not in poly.

With the XTEM approach in figure 13, the poly

was preserved, and the damage on both poly and

substrate can clearly be seen, corresponding to

the dark rings in the PTEM image.

Such a combination of an initial PTEM to

localize the defect, followed by an XTEM

through the defect, can be thought of as a type of

“three-dimensional” TEM, recently discussed in

the literature [10][11]. It solves the problem

having to guess at the defect position during

XTEM, but comes at a price – working with an

already very thin sample, which must now be

thinned along the other dimension.

The FIB has been used to prepare such samples

[9]. However, the beam damage that the FIB can

induce often results in poor TEM contrast.

Mechanical polishing of the PTEM sample to

form an XTEM sample solves this problem, but

requires exceptional skill. Figure 13 is such a

manually prepared sample.

The above results indicate three failure

mechanisms resulting in gate-oxide breakdown.

Each of them has distinct root cause. One is

residue-related and attributable to processing;

one is starting material related and attributable to

crystal defect (COPs); the last is test and

handling related and comes about as a result of

ESD damage. While traditional chemical

etching and decoration approaches would have

concluded “gate-oxide defect,” the underlying

real root cause would not have been clearly

identified, as it was using the above described

techniques.

Reference: Nathan Wang, Sabbas Daniel, TEM Direct Observation of Gate Oxide Defects, ISTFA 2002, Proceedings of the 28th International Symposium for Testing and Failure Analysis, 3-7 November 2002, Phoenix Civic Center, Phoenix, Arizona, pp. 765-769.

Figure 6: An EBIC image showing the hot spots

at end of poly line.

Figure 7: A PTEM image showing a residue in

the silicon substrate under the poly gate, causing

leakage current.

Figure 8: A PTEM image showing the gate oxide

pinholes on USB device.

Figure 9: A PTEM image showing a crystal

originated pit in an SRAM device.

Figure 10: A XTEM image showing the bird’s

beak residue causing gate leakage.

Figure 11: XTEM image showing the gate oxide

pinholes in the USB device.

Figure 12: XTEM image showing the crystal

originated pit in an SRAM device.

Figure 12: A three-dimensional TEM image

showing gate oxide pinhole.