Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

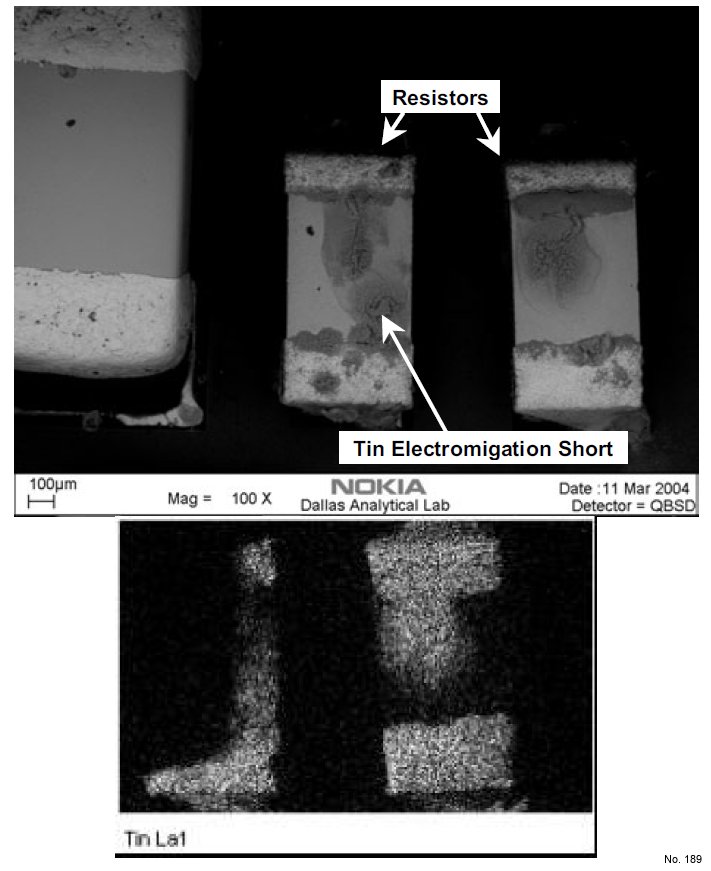

Tin Electrochemical Migration

Material Name: Sn

Record No.: 189

Primary Chemical Element in Material: Sn

Sample Type: Bulk

Uses: No data

Etchant Name: None

Etching Method: No data

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

Note: Tin electrochemical migration mechanism is similar to that

of Cu, but is much more prevalent because Sn constitutes a

major portion of several commercial solder compositions

such as 62SnPb2Ag, 10SnPb, Sn3.5Ag0.7Cu, etc. In

addition, exposed Sn is more widespread on an assembled

PWB as compared to Cu. The particular example shown in

Figure 1 is from a test vehicle that failed upon exposure to

damp heat testing. In this case, the potential difference

between the terminals of a resistor with Sn termination

resulted in the migration of Sn from the cathode towards the

anode. It can be seen from the EDX elemental maps (Sn)

that one of the resistors is shorted.

Reference: Sridhar Canumalla and Puligandla Viswanadham, Board Level Failure Mechanisms and Analysis in Hand-held Electronic

Products, Richard J. Ross (Editor), Microelectronics Failure Analysis, Desk Reference, Sixth Edition, ASM International, 2011, pp. 23-33.

Figure 1: Tin electrochemical migration on a resistor with

pure tin termination.